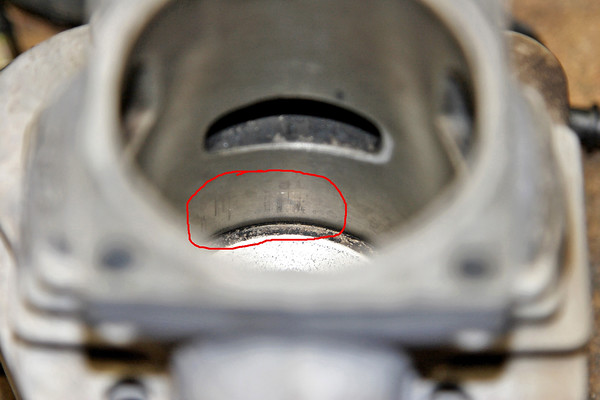

I'm working on a 066 Magnum. Some of the lining has been honed away on the side of the exhaust port. If I were to port this jug, I would go past the missing lining. I'm still concerned about it being too thin though.

Also, there are a few scratches above the exhaust port that didn't hone out. I cannot feel them.

The intake and transfers look good.

I'm guessing the top of the cylinder was over honed in trying to remove the scratches.

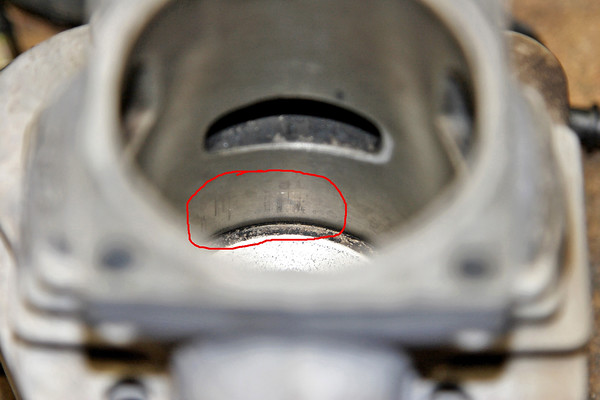

Also, there are a few scratches above the exhaust port that didn't hone out. I cannot feel them.

The intake and transfers look good.

I'm guessing the top of the cylinder was over honed in trying to remove the scratches.

Keep up the good work!

Keep up the good work!