wildbillx8

New Member

i would like to see picts. of what you use to fetch firewood.

Truth is , I was having a blast.

Truth is , I was having a blast. I think i may actually look forward to the snowstorms this year.

I think i may actually look forward to the snowstorms this year.

i would like to see picts. of what you use to fetch firewood.

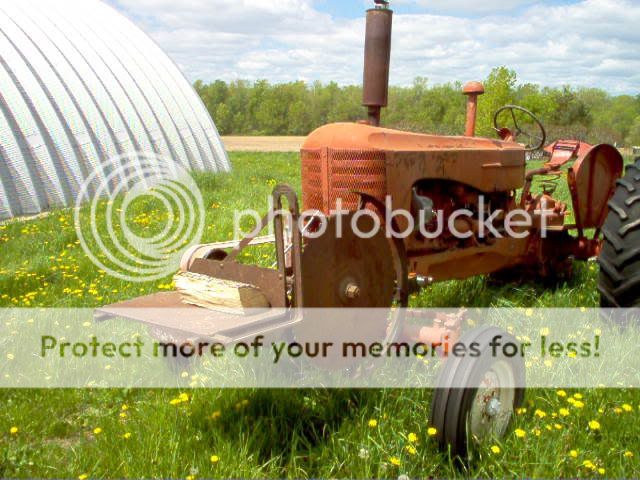

my old beater 800

This is what I use to get my firewood. Oh and I also wanted to show off the bridge I just built in my wood lot!

Oh and I also wanted to show off the bridge I just built in my wood lot!

This is what I use to get my firewood. Oh and I also wanted to show off the bridge I just built in my wood lot!

Oh and I also wanted to show off the bridge I just built in my wood lot!

We started out by making concrete forms out of 3/4" ply wood. Next we dug ledges on the creek bank 24" deep by 18" wide 8' long.Can you elaborate more on the bridge?

Heres two that I use.

I have a bucket that goes in place of the blade

Enter your email address to join: