Tzed250

Addicted to ArboristSite

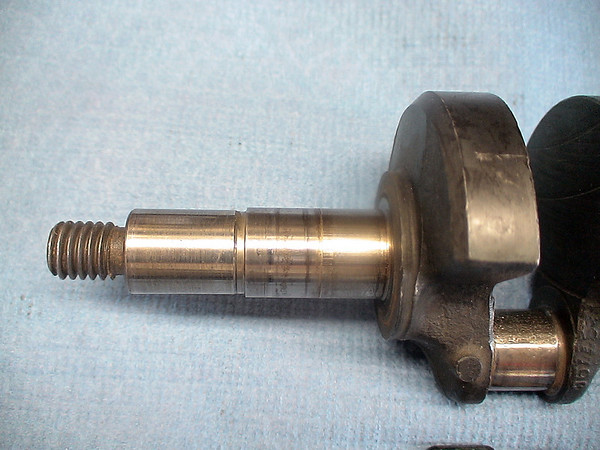

The connecting rod has the greatest amount of leverage on the crank when it is perpendicular to a line drawn from the crank centerline to the rod journal. Longer rods put more force into the crank, and less force as side thrust of the piston into the cylinder wall. The big end journal may not have been heat treated correctly.