Fighting with one of these for a Super 250. No primer, it's the model specific choke carb.

I'm a little stumped. I have a Sugar Creek kit for it, but I can't get it to pass fuel. I am tempted to play around with gasket stacking like Mark did, but of the 6 times I've tried, only once have I managed to get fuel to the pump chamber and beyond and I am unable to identify why it worked that one time. At no time, however, have I been able to make the saw run on anything other than a shot down the bore. Runs like a champ for 4 seconds when I do that! Just enough to tease me. In addition to the gasket stack, I have concern with the fuel filter pressed into the bottom. For now, that part is resting in a carb cleaner dip tank overnight to see what happens. I'll eliminate that problem source if all goes well tomorrow. I can make air go through evey passage on the carb, no blockages I can identify. I have not pulled the welch plugs only because I don't have any... yet?

Getting good with this thing. I can go from spread on the bench to installed test and back out to spread on the bench in under 5 minutes...

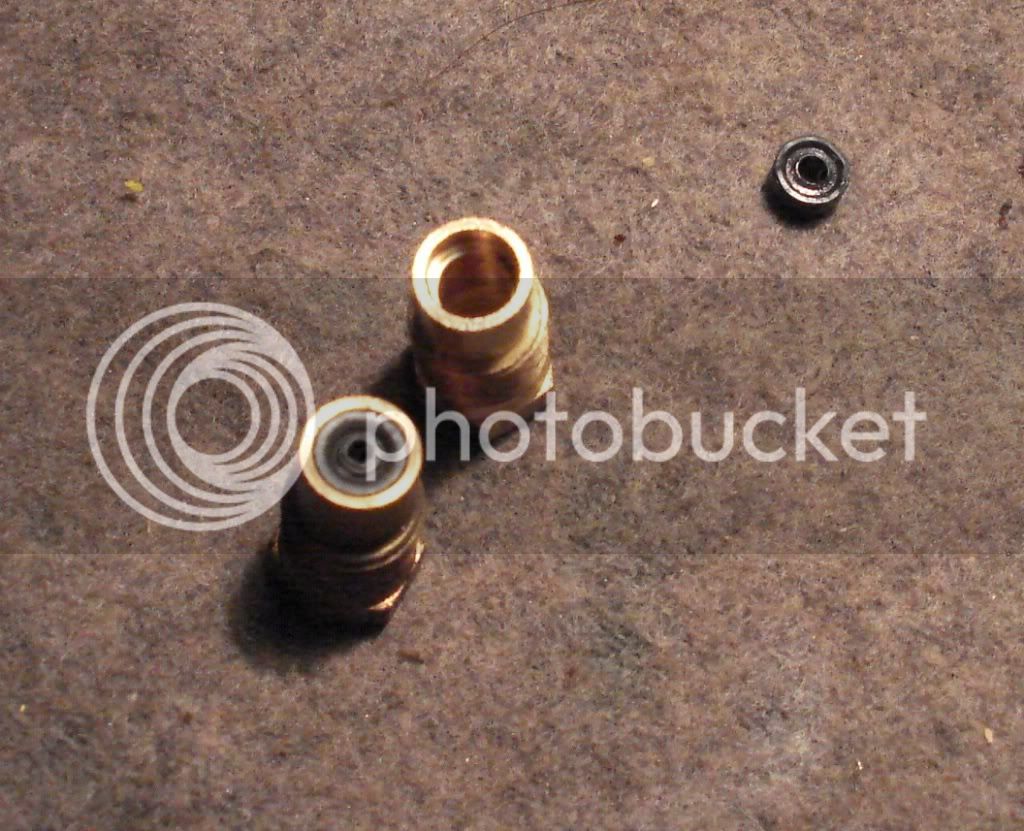

A few pictures. One thing different (besides the choke in place of the primer) is the metering seat is pressed in, not threaded.