jrobie79

ArboristSite Lurker

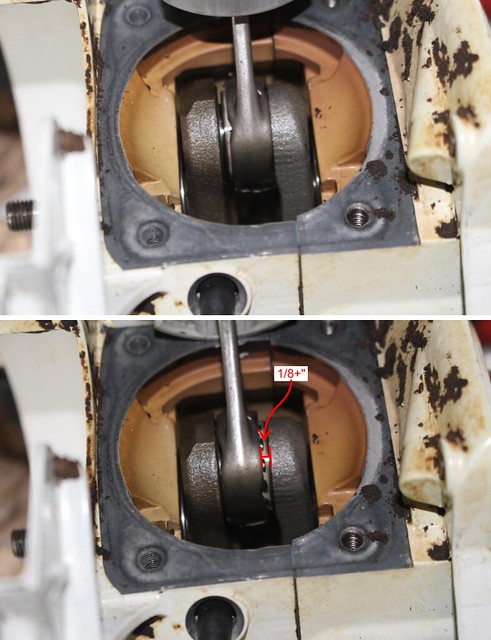

Long time lurker, first post. Been reading a bunch and just picked up a new to me ms361, it is absolutely filthy, so far I've probably picked off, wiped, scraped about a full pound of crap. So i started stripping it to clean it. See below:

Before I started tearing it apart I took a compression reading, and got just under 120psi. Is this acceptable? Haven't run the saw at all so I never took a warm reading:

The Piston looks ok from the exhaust and intake side (I'll get some pictures of that later).

My question is, what should I change while I'm in the process of putting everything back together since it'll be most stripped down? When I work on my car if I have to take a bunch of parts off I might as well swap in new smaller parts (hoses, plastic bits, etc...). I was thinking maybe some seals, rubber bushings, hoses, etc.

I've been using the factory service manual and this forum to take it apart and look forward to my new addiction and bring more active on this forum.

p.s. does anyone offer powder coating services? I'd like to get all the Stihl grey pieces refinished as I'm going to tackle the orange plastic restoration myself.

Before I started tearing it apart I took a compression reading, and got just under 120psi. Is this acceptable? Haven't run the saw at all so I never took a warm reading:

The Piston looks ok from the exhaust and intake side (I'll get some pictures of that later).

My question is, what should I change while I'm in the process of putting everything back together since it'll be most stripped down? When I work on my car if I have to take a bunch of parts off I might as well swap in new smaller parts (hoses, plastic bits, etc...). I was thinking maybe some seals, rubber bushings, hoses, etc.

I've been using the factory service manual and this forum to take it apart and look forward to my new addiction and bring more active on this forum.

p.s. does anyone offer powder coating services? I'd like to get all the Stihl grey pieces refinished as I'm going to tackle the orange plastic restoration myself.