User view

I'll defend the 575. I have both the 372 and 575, and put lot of hours on both. Yes, it is a little heavier, but you really don't notice it in the woods. Yes, it does take longer to warm up, but afterwards it will start at idle all day. There may be an issue with the bearings, mine went out (both sides), but not major failure, and the one plastic ball retainer that left the saw did no damage to the top end. Now for the little things I like: The oversize rear handle is really comfortable in my big hands. Sounds stupid, but much less fatigue. (The soft patch on the handle is starting to wear off though) I like the return to a one piece top cover. You are much more inclined to clean the cylinder and not just the air filter. It does have more torque in the cut. There just are not as many chain stalls as the 372. However, neither will hold a power candle next to my 7900, at approximately the same weight and size.

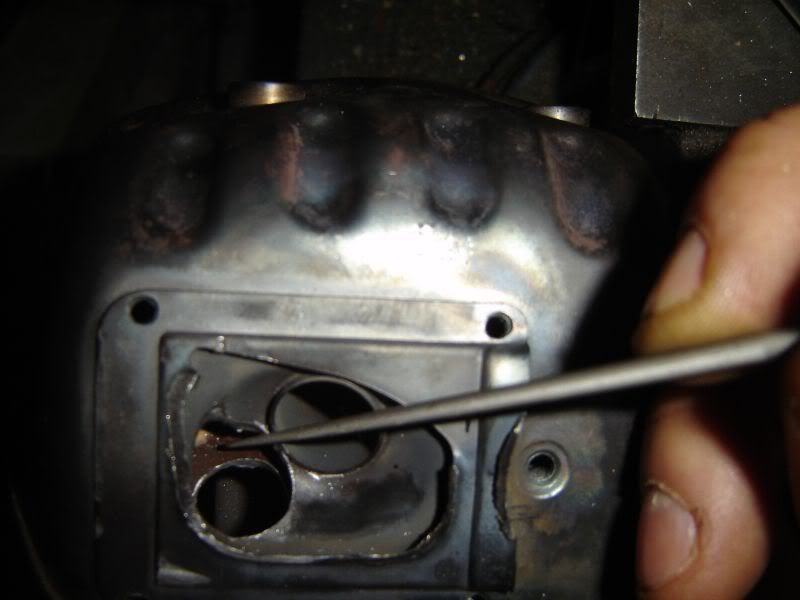

I'm glad to see a venture to mods on the 575. We will all have to learn the nuances of the stratified-charge engines, as this seems to be the coming technology. My saw is bone stock. When I had it apart, I was afraid to start taking on the challenges of the dual air path. I do think the muffler is restrictive, and heavy! The baffle that was drilled through in this tread adds weight and chokes the flow. A Walker-style pipe on the outside would do minimal good without dealing with the baffle. Nice job on this mod. Others??

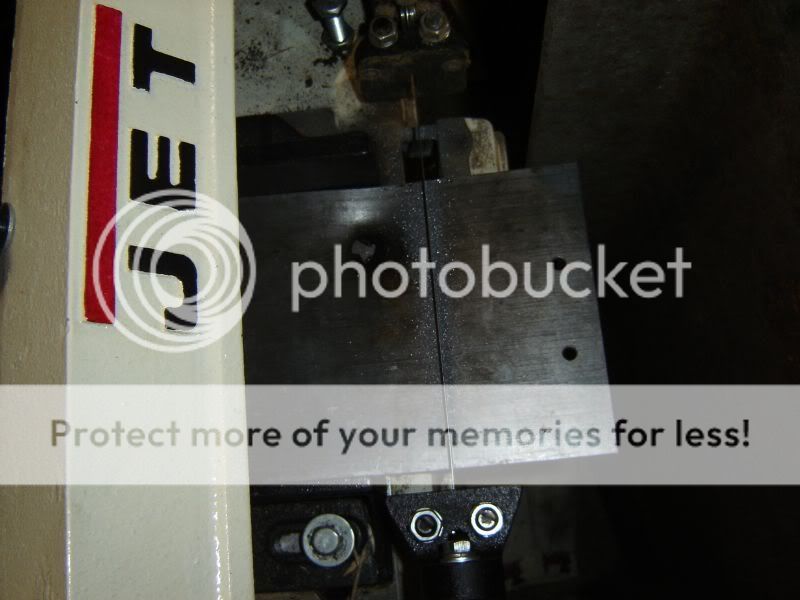

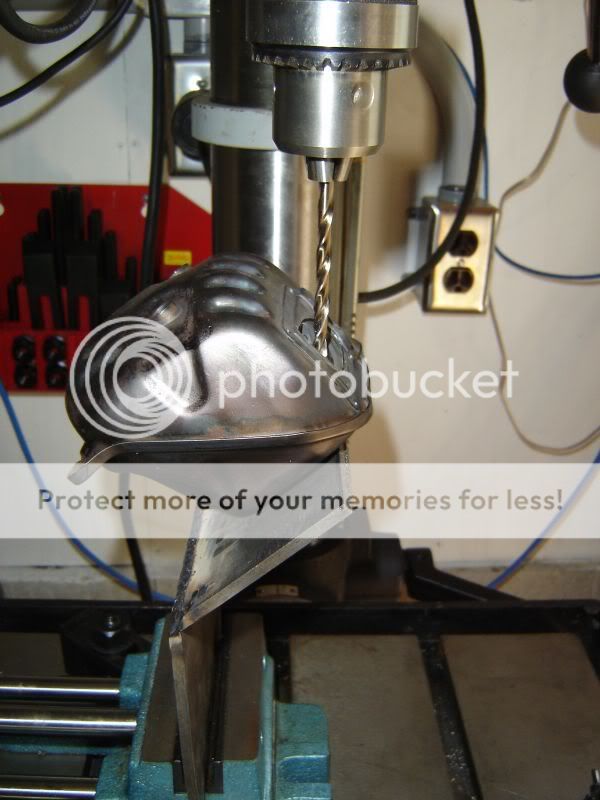

I see you have very good tools.

I see you have very good tools.