Wife'nHubby

Addicted to ArboristSite

Okay, guys, when I need help I admit it: I need help! (please)

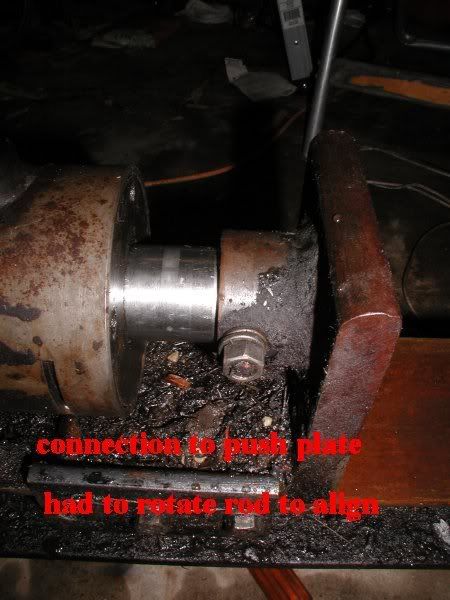

Here's my problem: Last fall hubby's two brothers came out to check out the problem with our splitter (leaking, squirting fluid). They took it apart for me and determined the seals, etc. had to be replaced. I took it to the repair shop and it's all fixed - but not yet reinstalled on the splitter.

The brother's-in-law haven't been back to put it together. One of them has a very valid reason (quadruple heart by-pass surgery) and the other brother-in-law doesn't respond.

So.... here I sit with a repaired cylinder that needs to be re-installed. I know nadda how it came apart but I do remember (somewhat) what it should look like when back together. This is not a name brand splitter, rather (I believe) a homemade job.

If I post pictures of the parts, can someone here give me direction on how to get this put together again? We bought 2 gals of 32 hydraulic oil today because I do know we will need to fill the cylinder, etc. If there is any bull work involved our youngest son can help me but he also knows nothing about hydraulics. Hubby also is here with me but can't help much anymore.

Geez, I really hate to ask for help.....

Shari

Here's my problem: Last fall hubby's two brothers came out to check out the problem with our splitter (leaking, squirting fluid). They took it apart for me and determined the seals, etc. had to be replaced. I took it to the repair shop and it's all fixed - but not yet reinstalled on the splitter.

The brother's-in-law haven't been back to put it together. One of them has a very valid reason (quadruple heart by-pass surgery) and the other brother-in-law doesn't respond.

So.... here I sit with a repaired cylinder that needs to be re-installed. I know nadda how it came apart but I do remember (somewhat) what it should look like when back together. This is not a name brand splitter, rather (I believe) a homemade job.

If I post pictures of the parts, can someone here give me direction on how to get this put together again? We bought 2 gals of 32 hydraulic oil today because I do know we will need to fill the cylinder, etc. If there is any bull work involved our youngest son can help me but he also knows nothing about hydraulics. Hubby also is here with me but can't help much anymore.

Geez, I really hate to ask for help.....

Shari