CoolCat44

ArboristSite Member

just got mine!

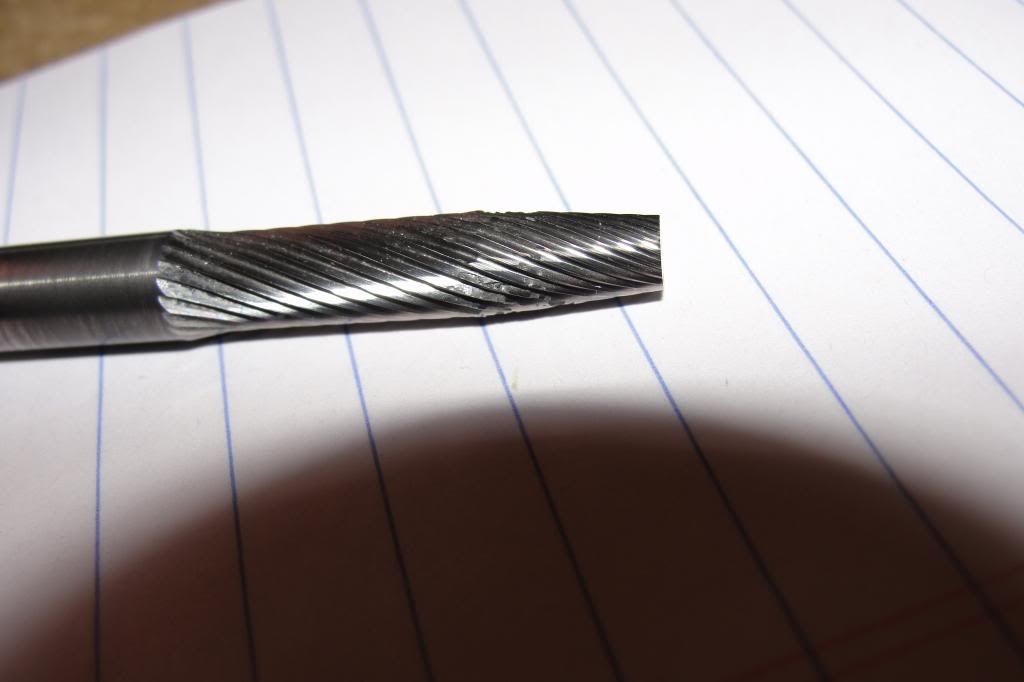

While waiting for delivery, I was keeping aside a couple chain for sharpening, then the Timbeline got here. Finally! What a nice quality tool!

Figuring how to make adjustment for the height, took me a coupe of tries. However, everything else is pretty idiot proof (hope not to insult!?!)

My 2 cents: For post-war chain, I will still be using my file, for end of life and almost worn out, still my good old 13/64 hand file + Stihl guide, but for light touch up Timberline is by far the best tool. And for regular sharpening also Timberline is pretty hard to bet.

Two thumbs up Timberline!

While waiting for delivery, I was keeping aside a couple chain for sharpening, then the Timbeline got here. Finally! What a nice quality tool!

Figuring how to make adjustment for the height, took me a coupe of tries. However, everything else is pretty idiot proof (hope not to insult!?!)

My 2 cents: For post-war chain, I will still be using my file, for end of life and almost worn out, still my good old 13/64 hand file + Stihl guide, but for light touch up Timberline is by far the best tool. And for regular sharpening also Timberline is pretty hard to bet.

Two thumbs up Timberline!