Not enough oil or a poor quality oil used

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

opinions on the demise of this Meteor 390 top end - big pic warning

- Thread starter Definitive Dave

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

idiotwithasaw

another row to hoe

They grey on top of the piston leads me to think lean condition. But I am by no means an expert chainsaw coroner. Even though I have brought a few back to life. Lol.

Frank Savage

ArboristSite Operative

Since it seems that intake is not scored, I suppose straightgasing it is not the cause. And the light brown on the squishband plus goldish tint in transfers leads me to think of leaning out. The wash atop of the piston is present even then, it needs leaning out to stop (run outta fuel in the middle of a cut) to have almost nonexistent wash on piston. Had seen one like that when the owner tuned it just to stop four stroking-but with no load and in less than 2 minute run time-then put the poor saw to work.

If the saw pass the vacuum test, then sure an operator error.

If the saw pass the vacuum test, then sure an operator error.

Definitive Dave

wanna-be saw racer, saw hoarder, parts whore

- Joined

- Jul 27, 2013

- Messages

- 2,118

- Reaction score

- 5,086

I intend this as educational and have removed all references to the buyer identity, I have no idea if they are a member here.

They have a little over 150 feedback, had already left me a positive and received one in return.

I initially got an Ebay return request which normally occurs when someone orders the wrong part (or occasionally we ship the wrong part), as below.

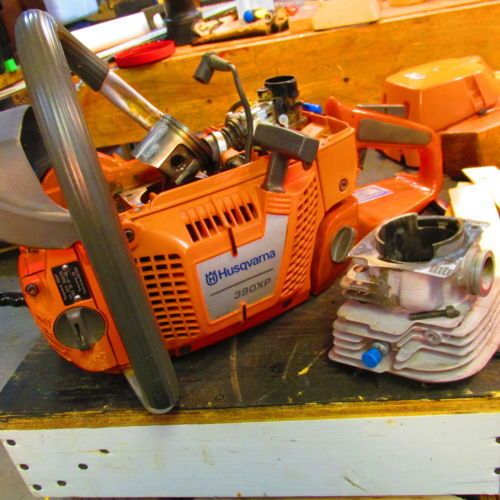

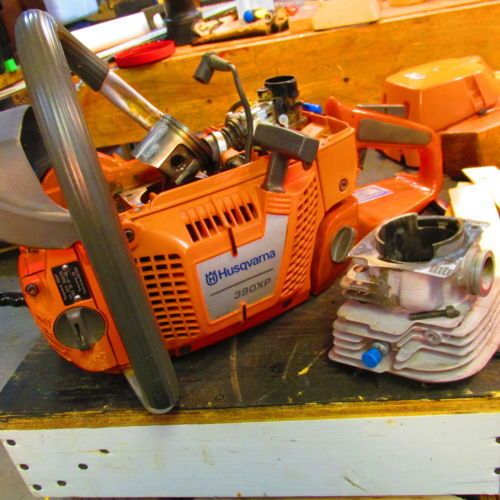

Husqvarna Chainsaw 390XP Meteor Cylinder kit 55mm CC2302 Caber Rings

Item ID:321877873471

Sale price:$130.00

Sale date:Nov-14-15 15:58:53 PST

Return opened:Nov-27-15 05:40:46 PST

Return reason oesn't work or defective

oesn't work or defective

Comments:

Recently I purchased a piston/cylinder set from you to repair my 3 yr old Husqvarna 390XP chainsaw. I installed it this weekend and was surprised to see that it seized up before running 1 gallon of fuel through the saw. I have attached pictures for you to see the mode of failure. The fuel mix was absolutely precise using Husqvarna oil. Please let me know how you wish to proceed.

My response sent to the customer as an Ebay message - cut and paste:

I sent you a return label through Ebay.

I have not seen any other failures on this product.

Did you do a pressure and vacuum test before and after installation?

Why did the original top end fail?

I did not get any pictures with your return request.

I will review the parts when they get here and check with the manufacturer to see how they want to proceed. Meteor has been very good to deal with on the single case in the past where we had a poorly plated product. I anticipate no problems with your return.

I will need documented answers to the questions in this message.

thanks

Dave

Customer response Ebay message - cut and paste:

No pressure test was done on the saw. Originally it was disassembled by a Husqvarna dealer (original seller) who indicated that the failure was due to lack of oil in the fuel mix. I don't have the original piston and cylinder, but I can say that the failure looked somewhat similar to the current problem, but much, much worse. He said that parts alone for the repair would be over $300.00, hence my attempt to purchase the lower cost piston/cylinder from you and do the repair myself. The dealer cautioned against using non-OEM parts.

Pictures were sent with the original request. I'll resend them with this communication. I wasn't aware that the return was contingent on your supplier's determination. Please let me know their answer as soon as possible.

My Second response to customer by Ebay message - cut and paste:

no just send it back, I guess I mean I will replace or refund, but my getting made whole by the supplier is based on the dead part, though the picture looks like bad fuel

sometimes the Ebay system does wacky stuff with attached pictures, there were none with the first message and only one with this message though it shows that there should be three pictures

thanks

Dave

I did already pay for a return label through Ebay for you

Reviewing the message later all three pictures were attached to the direct response from the buyer, included here:

They have a little over 150 feedback, had already left me a positive and received one in return.

I initially got an Ebay return request which normally occurs when someone orders the wrong part (or occasionally we ship the wrong part), as below.

Husqvarna Chainsaw 390XP Meteor Cylinder kit 55mm CC2302 Caber Rings

Item ID:321877873471

Sale price:$130.00

Sale date:Nov-14-15 15:58:53 PST

Return opened:Nov-27-15 05:40:46 PST

Return reason

Comments:

Recently I purchased a piston/cylinder set from you to repair my 3 yr old Husqvarna 390XP chainsaw. I installed it this weekend and was surprised to see that it seized up before running 1 gallon of fuel through the saw. I have attached pictures for you to see the mode of failure. The fuel mix was absolutely precise using Husqvarna oil. Please let me know how you wish to proceed.

My response sent to the customer as an Ebay message - cut and paste:

I sent you a return label through Ebay.

I have not seen any other failures on this product.

Did you do a pressure and vacuum test before and after installation?

Why did the original top end fail?

I did not get any pictures with your return request.

I will review the parts when they get here and check with the manufacturer to see how they want to proceed. Meteor has been very good to deal with on the single case in the past where we had a poorly plated product. I anticipate no problems with your return.

I will need documented answers to the questions in this message.

thanks

Dave

Customer response Ebay message - cut and paste:

No pressure test was done on the saw. Originally it was disassembled by a Husqvarna dealer (original seller) who indicated that the failure was due to lack of oil in the fuel mix. I don't have the original piston and cylinder, but I can say that the failure looked somewhat similar to the current problem, but much, much worse. He said that parts alone for the repair would be over $300.00, hence my attempt to purchase the lower cost piston/cylinder from you and do the repair myself. The dealer cautioned against using non-OEM parts.

Pictures were sent with the original request. I'll resend them with this communication. I wasn't aware that the return was contingent on your supplier's determination. Please let me know their answer as soon as possible.

My Second response to customer by Ebay message - cut and paste:

no just send it back, I guess I mean I will replace or refund, but my getting made whole by the supplier is based on the dead part, though the picture looks like bad fuel

sometimes the Ebay system does wacky stuff with attached pictures, there were none with the first message and only one with this message though it shows that there should be three pictures

thanks

Dave

I did already pay for a return label through Ebay for you

Reviewing the message later all three pictures were attached to the direct response from the buyer, included here:

Frank Savage

ArboristSite Operative

I would say that IF he installed the cylinder with the same degree of disassembly as in the last pic, there was an airleak on the bottom of the improperly positioned intake boot-or it may scrape through it over the clamp edge. Needs some experience to correctly instal intake boot onto cylinder with the boot and carb in place with this intake style. A little leak, his usual tune "just shy of too lean" and the result is obvious. For me, his photo with the fresh red-brow-goldish tint and all the scratches being on the left (upper in non-fullwrap gunning cut scenario) just screams too lean to me, with 99+% bet on operator´s (assembler´s ) error.

Just my 0,01

Just my 0,01

Definitive Dave

wanna-be saw racer, saw hoarder, parts whore

- Joined

- Jul 27, 2013

- Messages

- 2,118

- Reaction score

- 5,086

I gotta refund him, not worth arguing or bad blood over a chainsaw part but I can t justify asking Meteor for a freebie on this one, I don't see any evidence of manufacturer error.

Seeing the responses from guys with more wrench time on any particular model than my entire lifetime will see on all models combined is what makes posting here a constant learning experience.

You guys rock!!!

Seeing the responses from guys with more wrench time on any particular model than my entire lifetime will see on all models combined is what makes posting here a constant learning experience.

You guys rock!!!

KG441c

Keith

It was ran lean no doubt

Does eBay make you do a refund in this instance? If so we all can clearly so it was the assemblers /operators fault . Dave I actually feel sorry for you . I would not refund or replace anything . But you are right from a business stand point . plus we all know you are a great guy !

idiotwithasaw

another row to hoe

I will say this, I rebuilt my 390 with a am top end before meteor made a kit. It was earlier on in my learning process. And I slapped it together and went to use it, ran great, used it to cut down some mulberries that had grown next to the shop not that big 6-12". So I decided to take it and cut a stump. It ran great, till I was halfway through and it just died. I pulled the muff and my heart sank. I was mad cause I went the am route to save money and not have a lot in this build and here I was looking like I was gonna end up with oem money in am parts. I freely admit that when I first assembled it that I didn't pressure check it, but I checked it after it failed and it didn't leak at all. The only thing that I can think of that caused it was that I left the carb settings where they were and didn't refine cause at the time I didn't have a tach and knew way less about tuning a saw than I do now, which is still admittedly questionable. The thing is I was aware of this and fully intended to take it and have it tuned but my itchy throttle finger won out over common sense. So I ordered another am piston, jug cleaned up thankfully, and properly vac/press tested it and had the carb set.

idiotwithasaw

another row to hoe

Haven't had a problem since. I'm still not happy with it, but that's less from performance, than knowing it's not at least an oem cylinder.

idiotwithasaw

another row to hoe

I agree Dave, I wouldn't ask for a refund. I knew the problem was my fault for not being thorough. And I wouldn't expect you to give one either. This guy is a D-bag and the exact reason why I hesitate to sell anything on the bay.

I would either refund him or fight it because he never fixed the reason for the first failure like Beagle said in a previous post. If you send him another topend it will turn out just like the last 2. My guess is a crank bearing going bad and the seal leaking under load or just flat adjusted too lean. Probably limbs with the saw pegged, not the best for a 390 bottom end. CJ

sunfish

Fish Head

As a business man I would also refund it, not replace it. I would use this as a learning process and let him know that this was operator error. If people are replacing scored top ends they need to know to look for air leaks and bad tunes. Send him a link to this thread.

beaglebriar

ArboristSite Operative

Far as I'm concerned once a part has been installed and ran they own it. But that's just me.

Sent from my XT1080 using Tapatalk

Sent from my XT1080 using Tapatalk

Ok lets admit it, lots of us "WERE" mechanics of some sort prior to becoming "saw guys" ...as lots of mechanic know, replace parts and start the engine again to find out what additional parts we need to replace. Rinse, repeat...it pisses mechanics off when they actually have to "PAY" for their dependence on "replacement" rather then "diagnosing" faults...its usually just the "client" who pays. This time the mechanic wants Dave to pay for his education...and not the poor random customer...

No insults are intended here but lots of guys can rebuild a small block chevy in their sleep but can't rebuild a chainsaw 2 stroke engine properly. It may start and run, but how long is the question.

Sucks for Dave as it looks like he is eating this one.

No insults are intended here but lots of guys can rebuild a small block chevy in their sleep but can't rebuild a chainsaw 2 stroke engine properly. It may start and run, but how long is the question.

Sucks for Dave as it looks like he is eating this one.

Frank Savage

ArboristSite Operative

No nics, just wood filings from dirty hands and mess around the carb area, as he was disassembling it. The "nics" are obviously above the cylinder surface and there is no trace of anything on the intake side in Dave´s pics on the first page.

I feel sorry for ya Dave, this realy $uck...

I haven´t ever had a tach. After every disassembly, I just turn the crab pig rich (as that the saw barely runs from being flooded, or stops after 10-15 sec of constant idle because of that), make it run 1-2 min to warm a bit and wash out any possible mess left behind with the oversupply of oil, then lean the saw gradiously to right tune. And always I have tendency to be on the rich side, ie. black-brown residue... (OK, I use oil which leaves about 1/10 of Stihl or Husky oil amount of ash)

I feel sorry for ya Dave, this realy $uck...

I haven´t ever had a tach. After every disassembly, I just turn the crab pig rich (as that the saw barely runs from being flooded, or stops after 10-15 sec of constant idle because of that), make it run 1-2 min to warm a bit and wash out any possible mess left behind with the oversupply of oil, then lean the saw gradiously to right tune. And always I have tendency to be on the rich side, ie. black-brown residue... (OK, I use oil which leaves about 1/10 of Stihl or Husky oil amount of ash)

im talking on the second page pics looks like nicks below the intake . im no pro but when i rebuild i always change atleast the seals if piston is scored check the hoses and change the bearings if i find just a least little bit of roughness in the bearings as the roughness is a sign of being hot before

Similar threads

- Replies

- 8

- Views

- 1K

- Replies

- 2

- Views

- 388