pioneerman

ArboristSite Operative

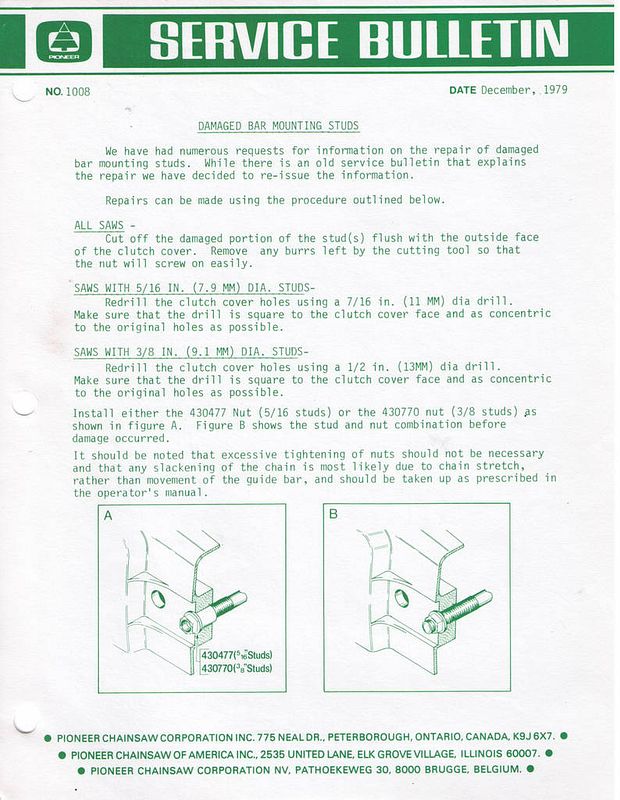

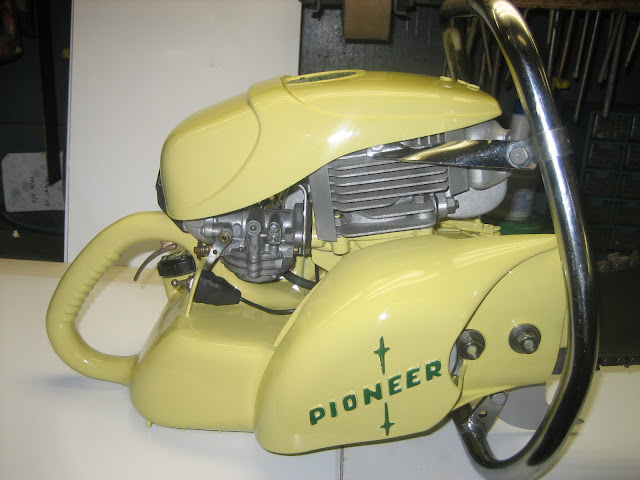

Brian. I haven't taken the bar studs out of any of my saws, but they should turn out counterclockwise. I don't think you have to take the clutch off to get the studs out. Take off the clutch cover, and then double nut the stud that you want to remove. Tighten the nuts against each other and then put a wrench on the lower nut and turn out the stud. On the large frame P series saws the studs are torqued to 18-20 foot pounds so the 1073 is probably less and should turn out easily enough. Let us know how you make out.