crmyers

ArboristSite Operative

Thanks, I'll have to make an order.

All I can say is, WOW, cutting off those tab limiters on the carb helped me to get it running pretty well by just ensuring the screws were out 1 1/4 turns.To add a point to this thread, do not forget that the carb screws often have tabs on them to limit the screws, and they need to be cut off.

I have mine cut off now, but need to run out and attend to some errands, so won't be able to get around to this until later, to see how I can tune it.

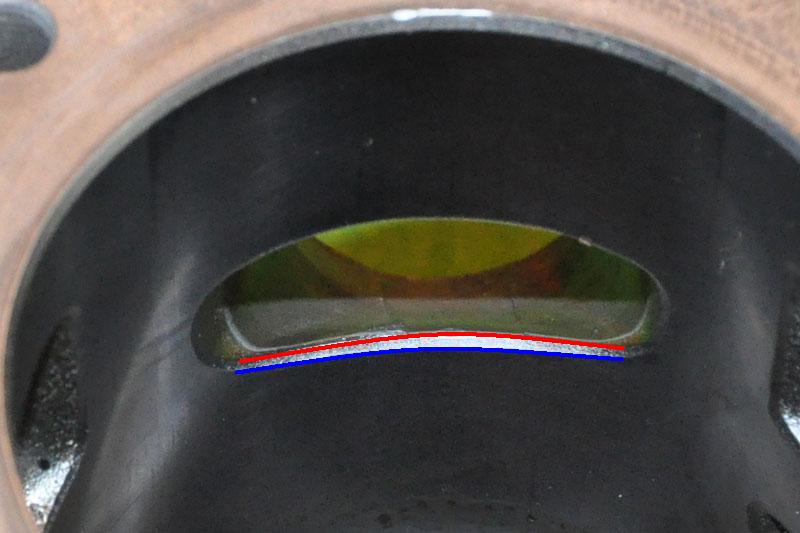

You'll need the piston to know how wide the skirts are and where the ring ends are.

Polished on the exhaust side is fine. On the intake, leave it semi rough. I leave the finish my carbide burr makes.

Enter your email address to join: