Lakeside53

Stihl Wrenching

Be careful Brad.. next you'll have a lathe, a mill, and have way more money in tooling than all your saws forever... LOLOL

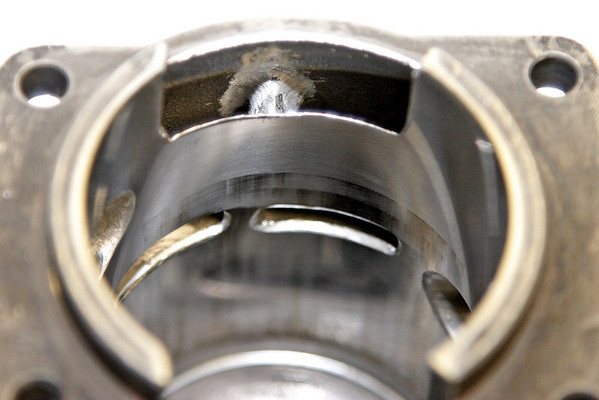

As for you piston.. Make something to hold it in your drill press, spin it fast and just touch emery paper on a ridgid holder (wooden stick) to the outer 1/3 of the top (no need to take off the entire top. Measure as you go...

then go buy a lathe

As for you piston.. Make something to hold it in your drill press, spin it fast and just touch emery paper on a ridgid holder (wooden stick) to the outer 1/3 of the top (no need to take off the entire top. Measure as you go...

then go buy a lathe

My time before was 6.4x If I recall correctly.

My time before was 6.4x If I recall correctly.

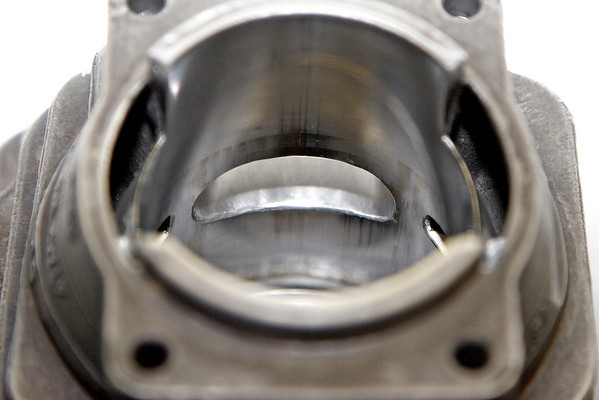

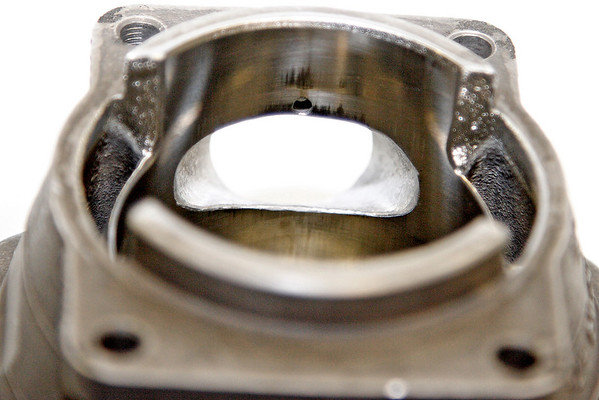

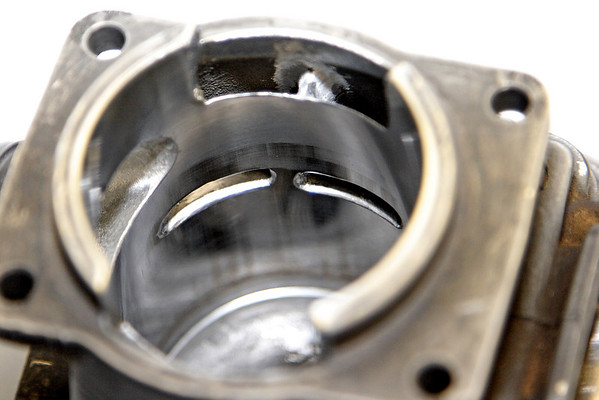

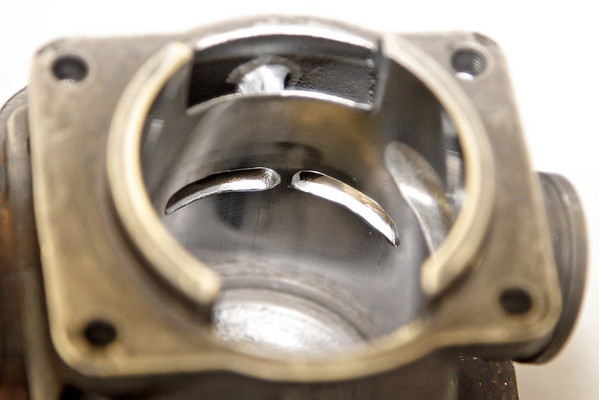

Oh, I pulled the muffler back off too and the piston still looks like new. Another saw has been Snellerized and has become a BS361. Now I just need to get my hands on a 084.

Oh, I pulled the muffler back off too and the piston still looks like new. Another saw has been Snellerized and has become a BS361. Now I just need to get my hands on a 084.