harrygrey382

Addicted to ArboristSite

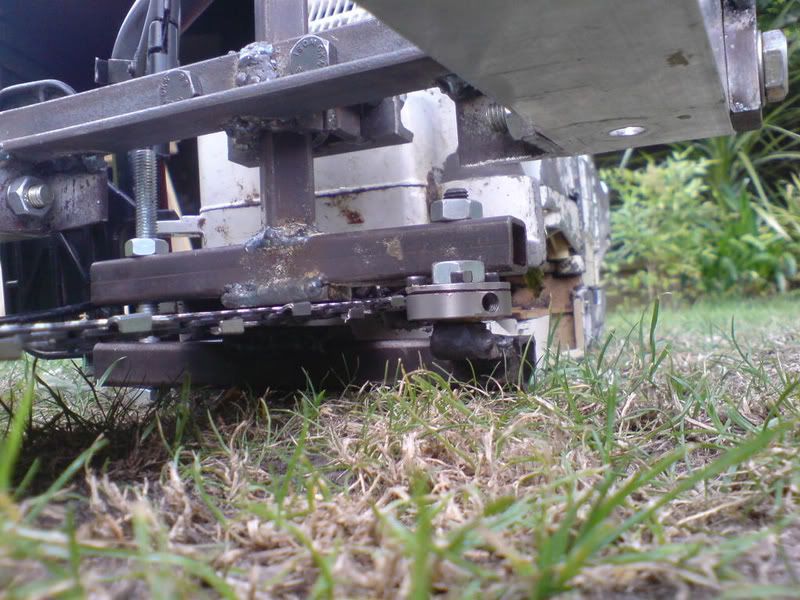

So I got a chance to do some improvements on my DIY Alaskan. First up was a handle - splaying the arms on the uprights wasn't good, not to mention the vibes. So an old bike and table frame came in handy...

Next - a hand throttle. I was planning on copying BobL's BIL throttle set up. Then I decided it might be possible to go in earlier on towards the carb. I got one of those cable clamp bolts (a push bike can take a CSM a long way!) from a brake and threaded it over the throttle arm and put a rubber washer on top. Then ground a groove in a washer to stop the cable moving when tightening the whole lot down. It looks like the cable's fowling in the carb body but it runs totally free.

Then I made a bracket to capture the cable and used a longer bolt to attach it via the front handle mount (cable not tightened here).

Next - a hand throttle. I was planning on copying BobL's BIL throttle set up. Then I decided it might be possible to go in earlier on towards the carb. I got one of those cable clamp bolts (a push bike can take a CSM a long way!) from a brake and threaded it over the throttle arm and put a rubber washer on top. Then ground a groove in a washer to stop the cable moving when tightening the whole lot down. It looks like the cable's fowling in the carb body but it runs totally free.

Then I made a bracket to capture the cable and used a longer bolt to attach it via the front handle mount (cable not tightened here).