I assume your old grinder will now just do raker duty. Did you actually find this jewel east of the Mississippi, or did you have to import it from the west? Ron

It came out of the West. Got a pretty good deal on it, used very little. There were two other grinders for sale, both from the same seller and he wasn't asking very much for them either. PM me and I'll give you the information if you want.

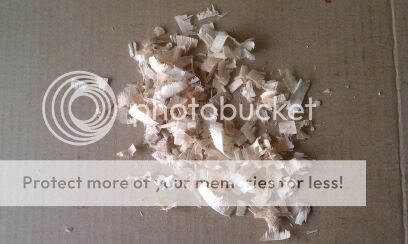

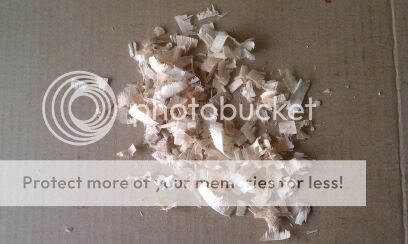

I figured you would like it. Keep playing with the angles and it will self feed pretty good. The wider the side plate also will make big fat chips. Just be careful when you do as it can cut into the tie straps too much and can break them.

When you get the angles where you really like them pick up a blue ceramic stone. It holds its edge better and makes a crisper corner. They're almost double the price of the other stones but worth it.

My practice chain is toast, cut several of the straps! I'm calling Silvey today, the light was broken in transit and the arm being swung to the right doesn't match exactly, its off by about 1/16" requiring me to adjust the chain bar height. I think either the arm bolt needs tightened or worst case the arm is bent. I'm also needing stop pawls as the seller somehow ground them to a point and one of the diamond dressers is missing the wing nut on top.

It came with 3 Silvey grinding wheels an one Madens, who sells the blue one? I noticed they have a little bit of wobble to them, I'm guessing the blue stone is made to tighter tolerance's?

Dennis Cahoon in a post from long ago mentioned that the swing arm could be made to make better chain than most square grinders by slotting the chain bar to prevent it from slipping and allowing movement in only one direction. I'm going to ask him about it. The post mentions he knows a guy that can turn the swing arm into the most adjustable grinder out there or at least the best priced one with full adjust-ability.

I'm sure you and I will talk a few more times, thanks for helping!

Is square grinding something that can be applied to semi-chisel chain or does this only apply to full chisel chain?

Thanks!

I don't think you can square semi-chisel because there is no corner to the cutter.