HorseShoeInFork

ArboristSite Operative

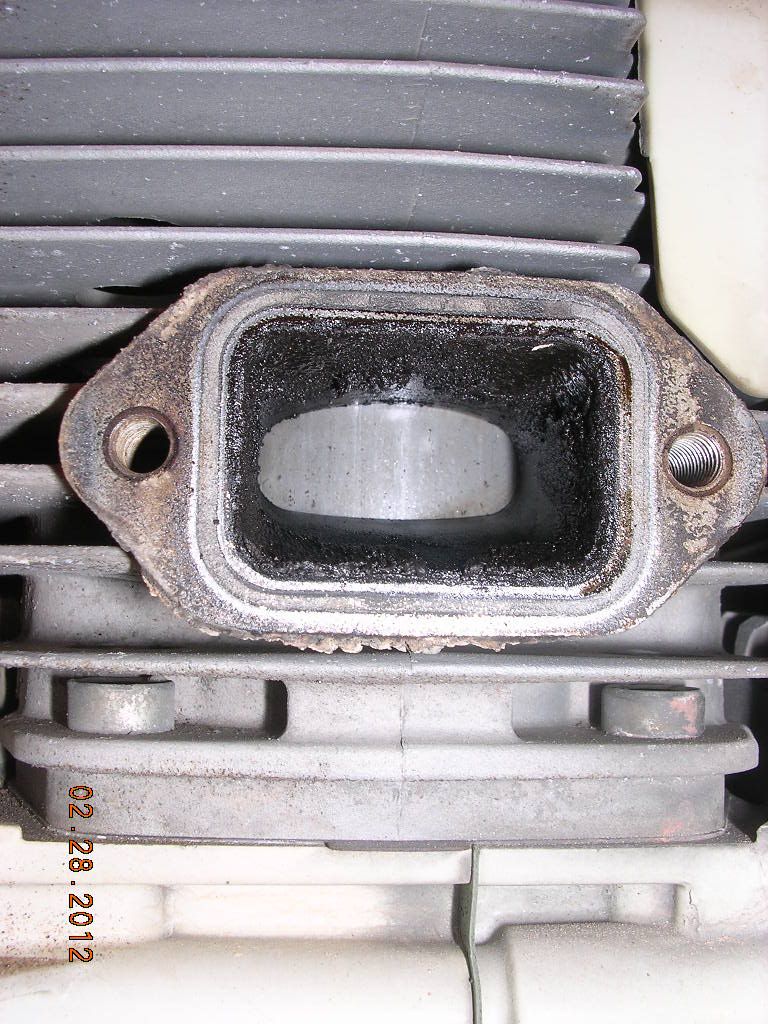

I have a Stihl TS400 that I can get to pop occasionally, but won't start. Gas runs out the air filter after pulling it a dozen or so times. It does have a good spark and fresh gas. The decompression button stays down like there may be a piece missing; you can manually pull it up but it falls back down easily. I can't pull the muffler to look at the cylinder because the bottom torx head screw is almost non existent.