Mastermind

Work Saw Specialist

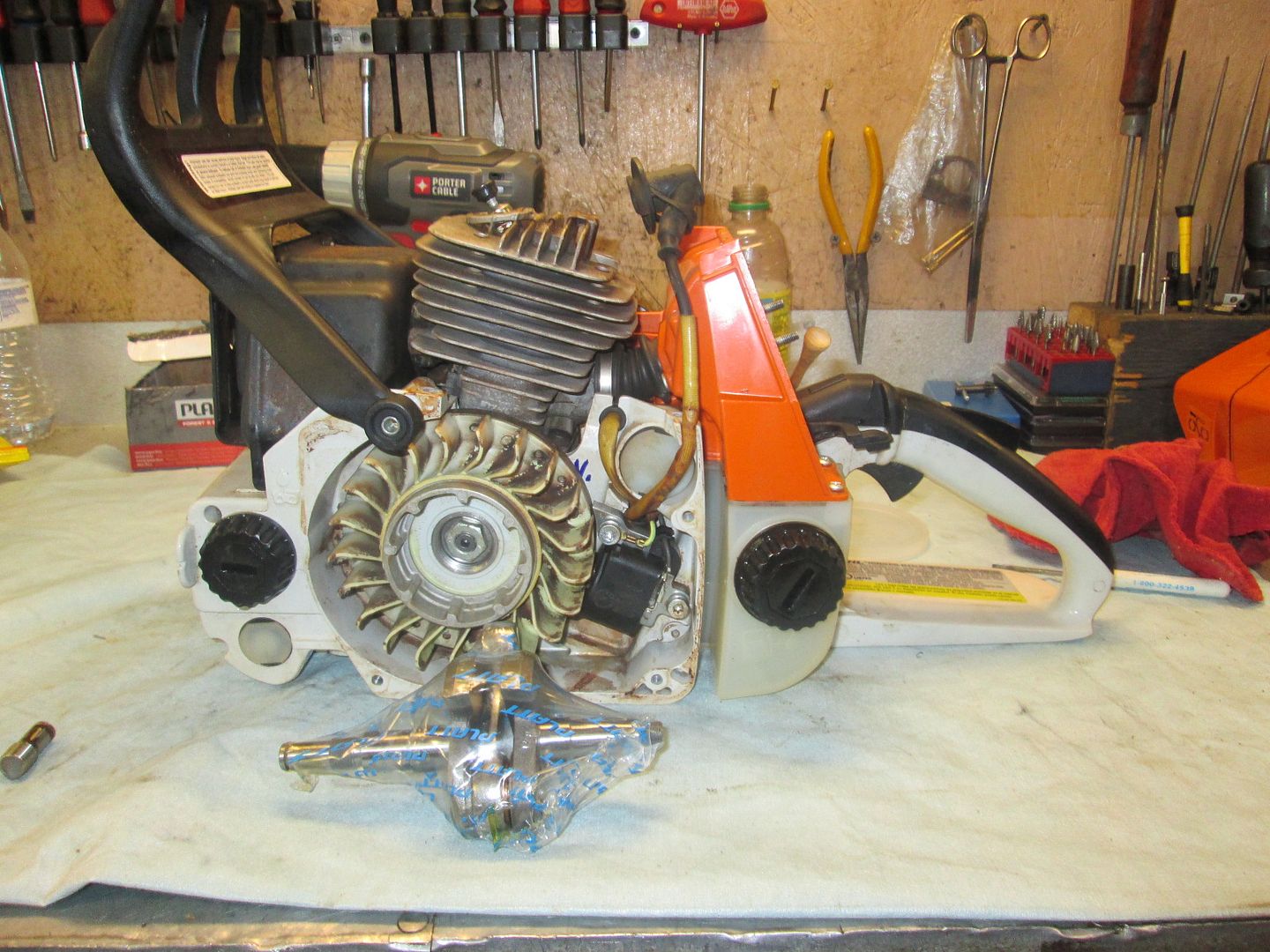

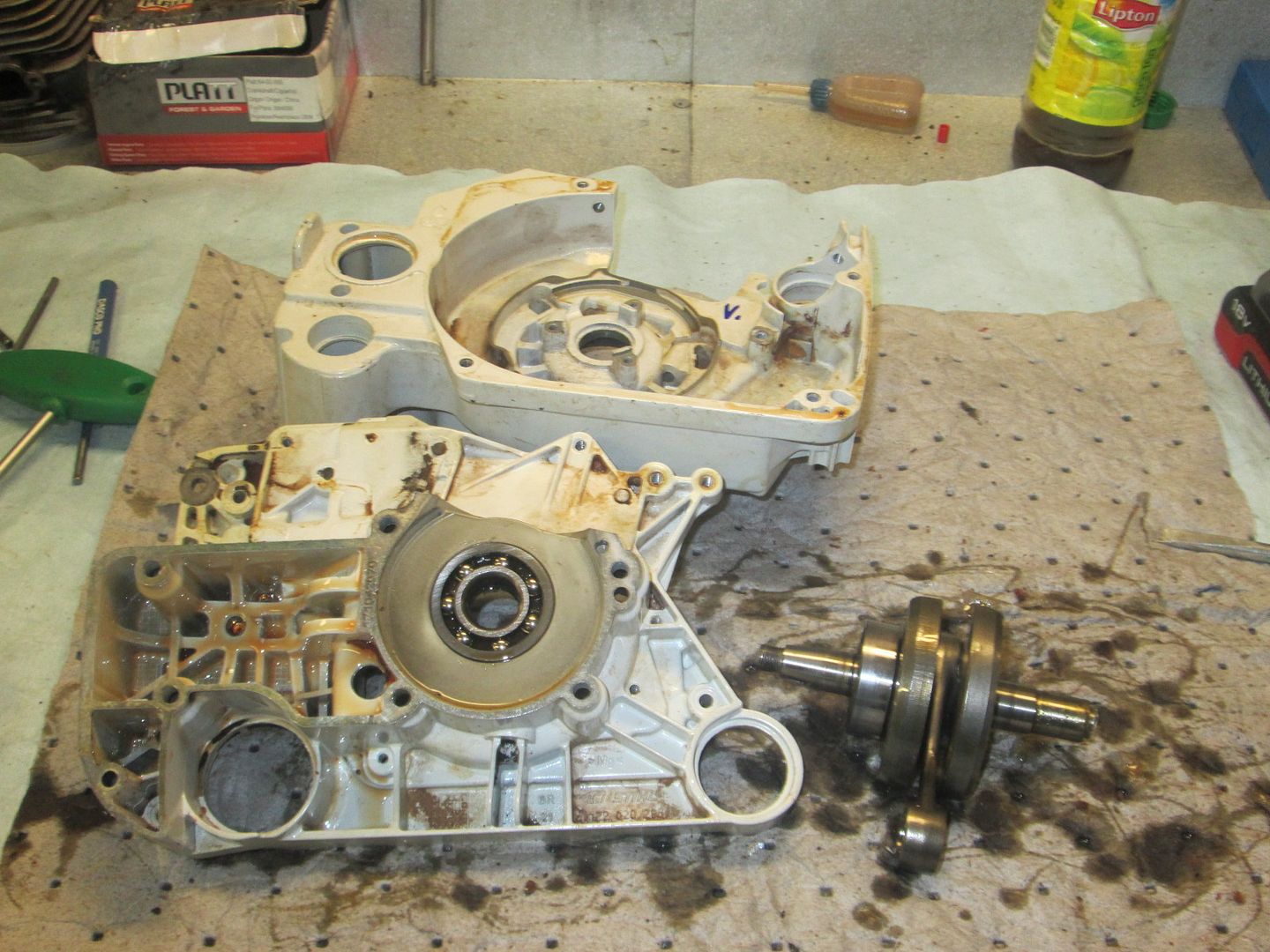

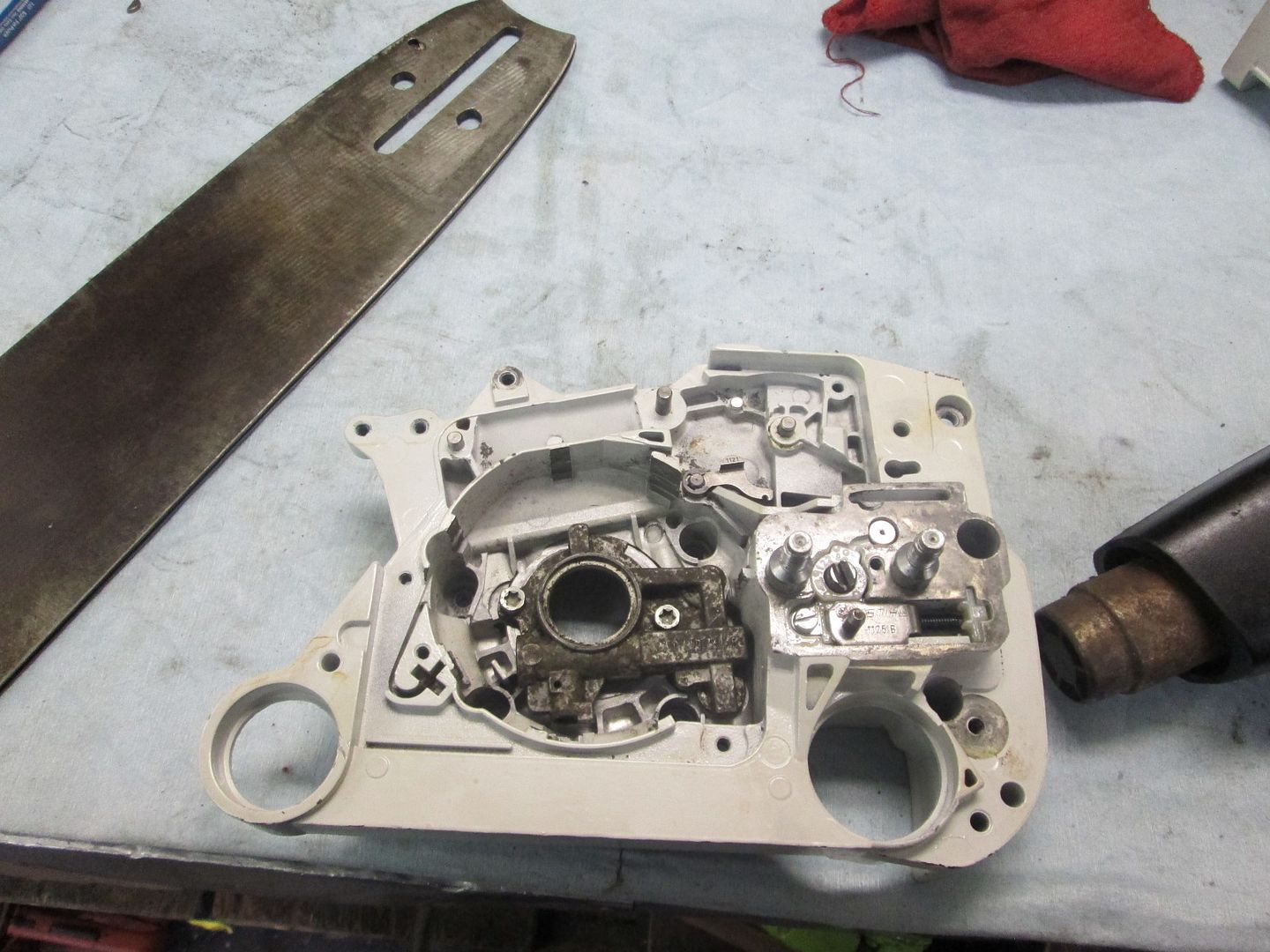

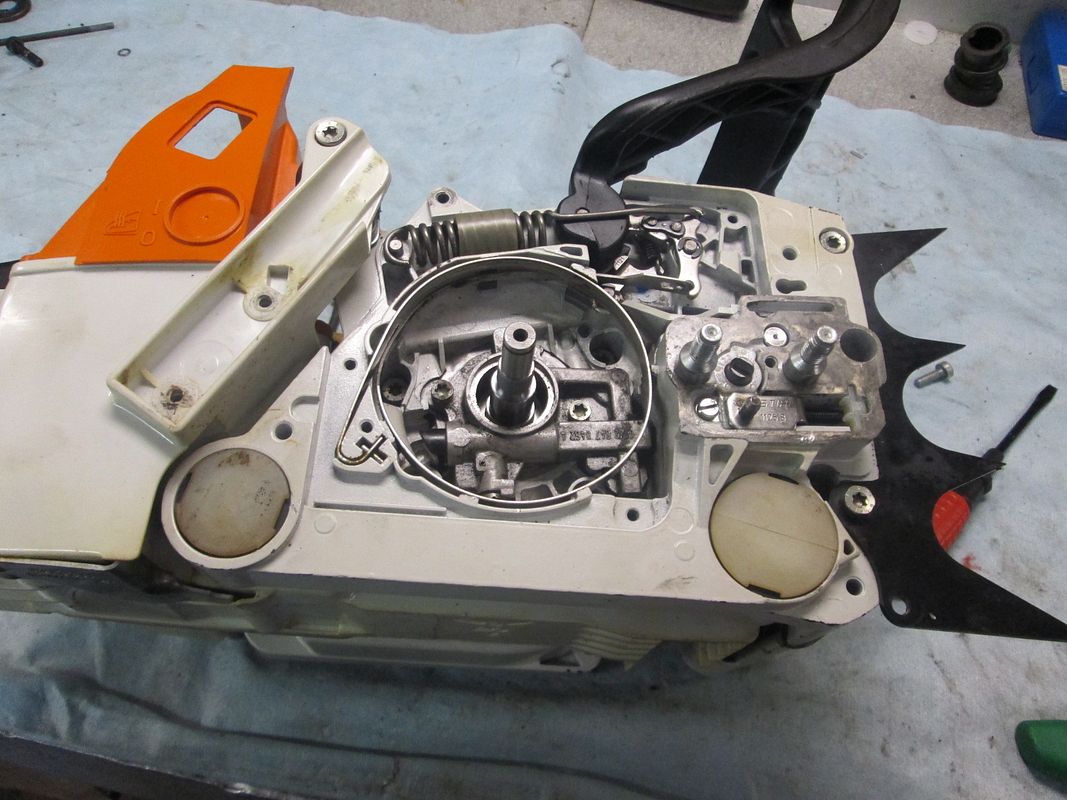

The crankshaft broked off on this here saw.

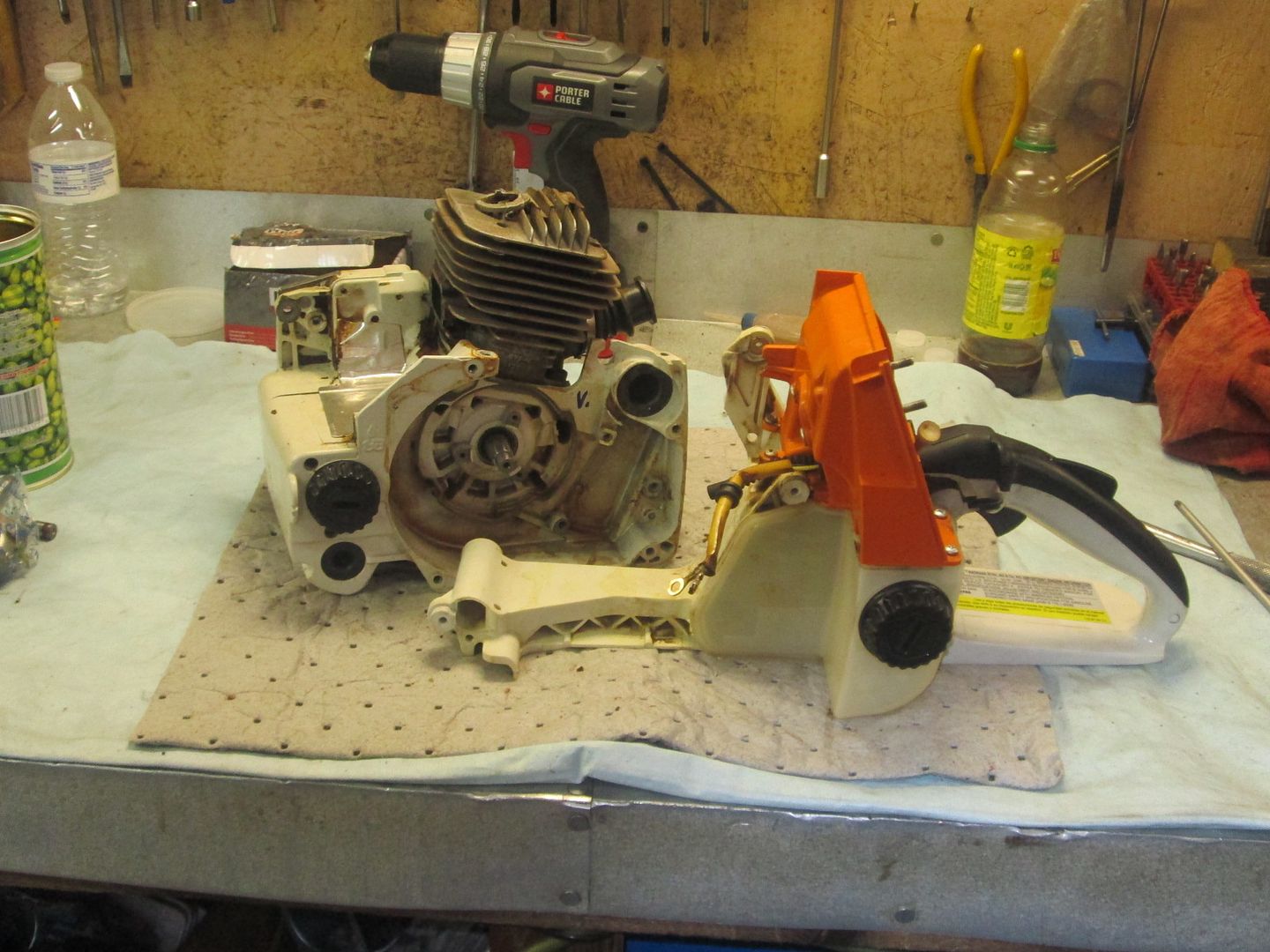

Brian killed it......but Jon is fixing it.

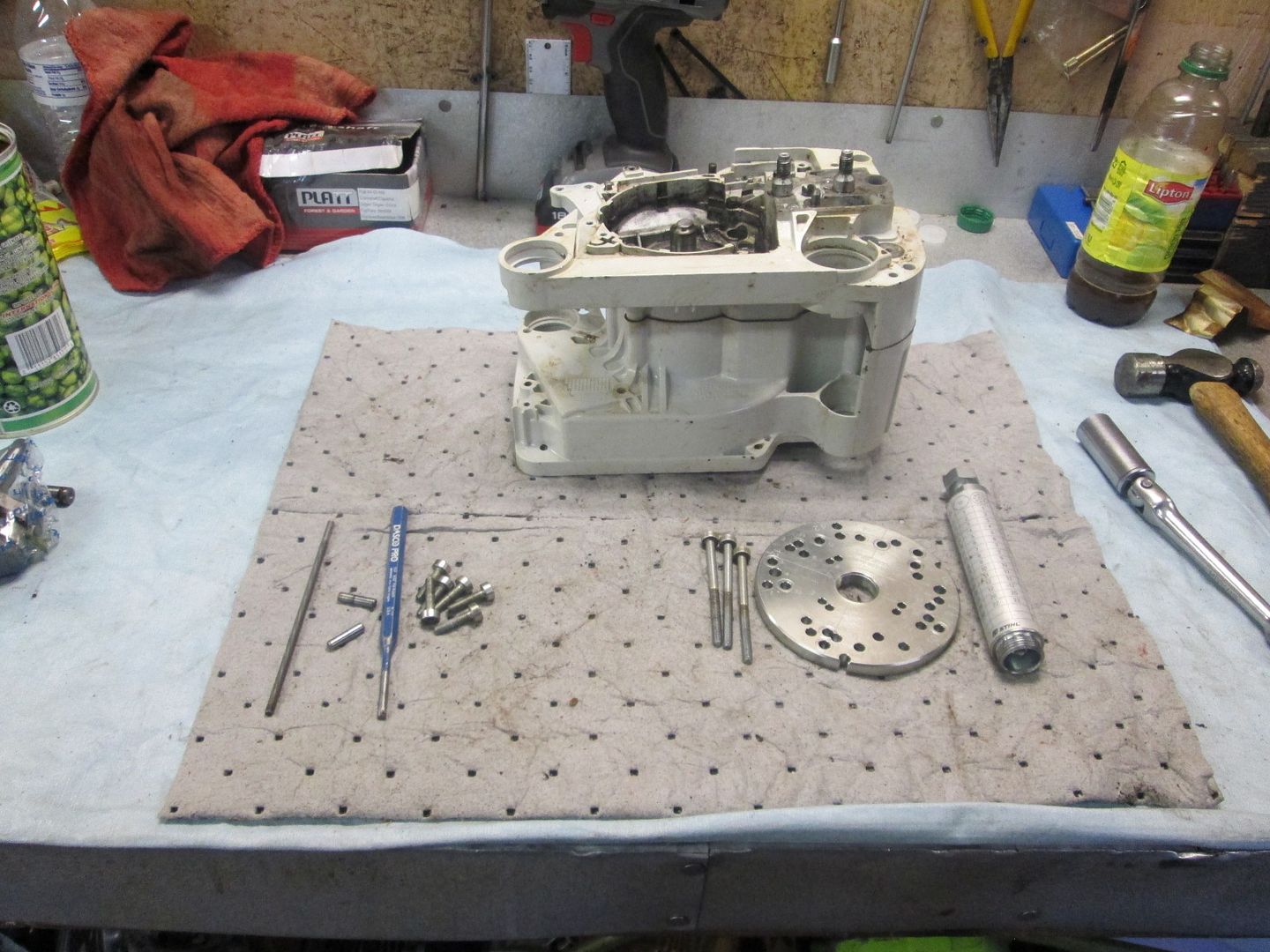

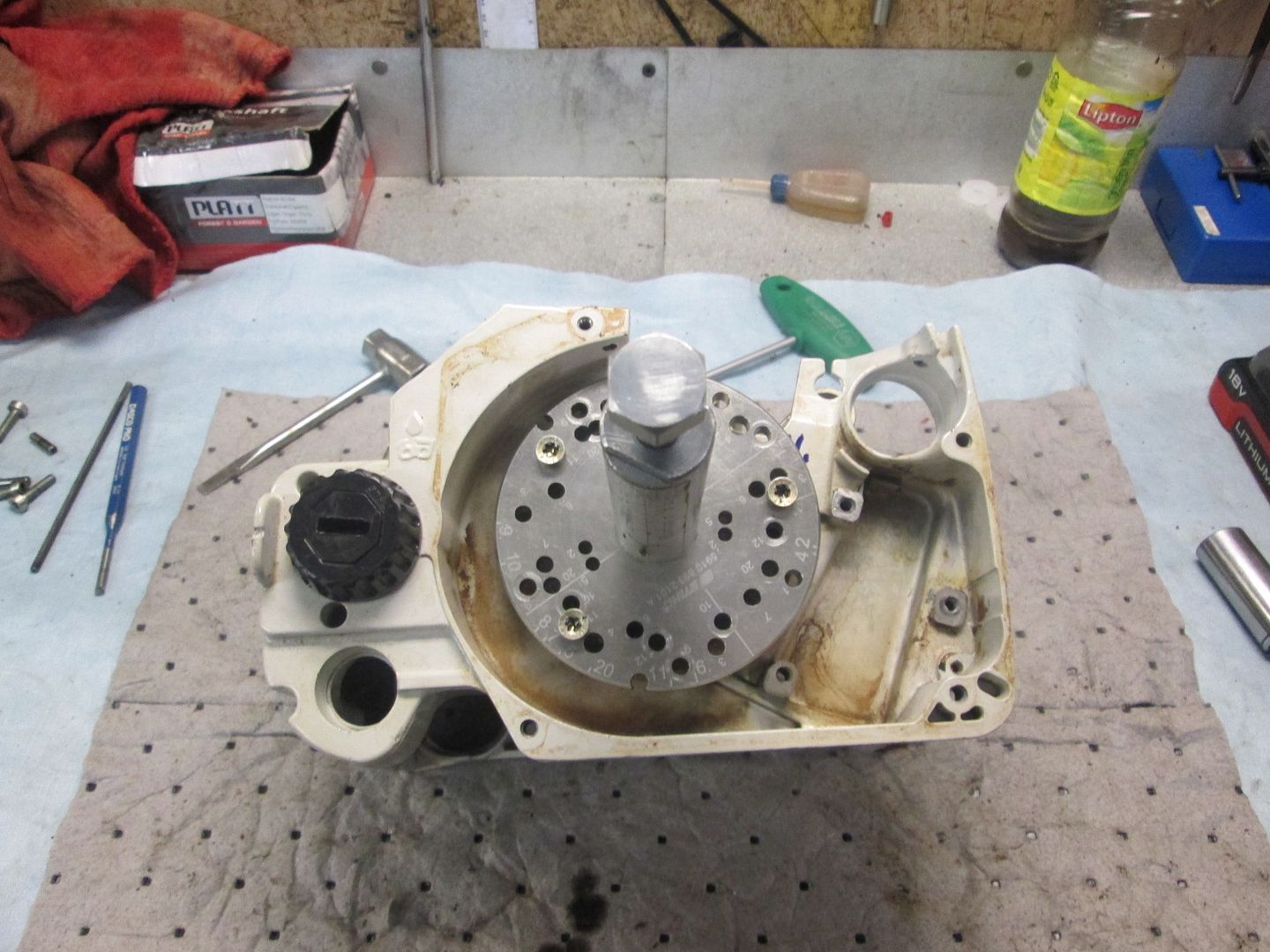

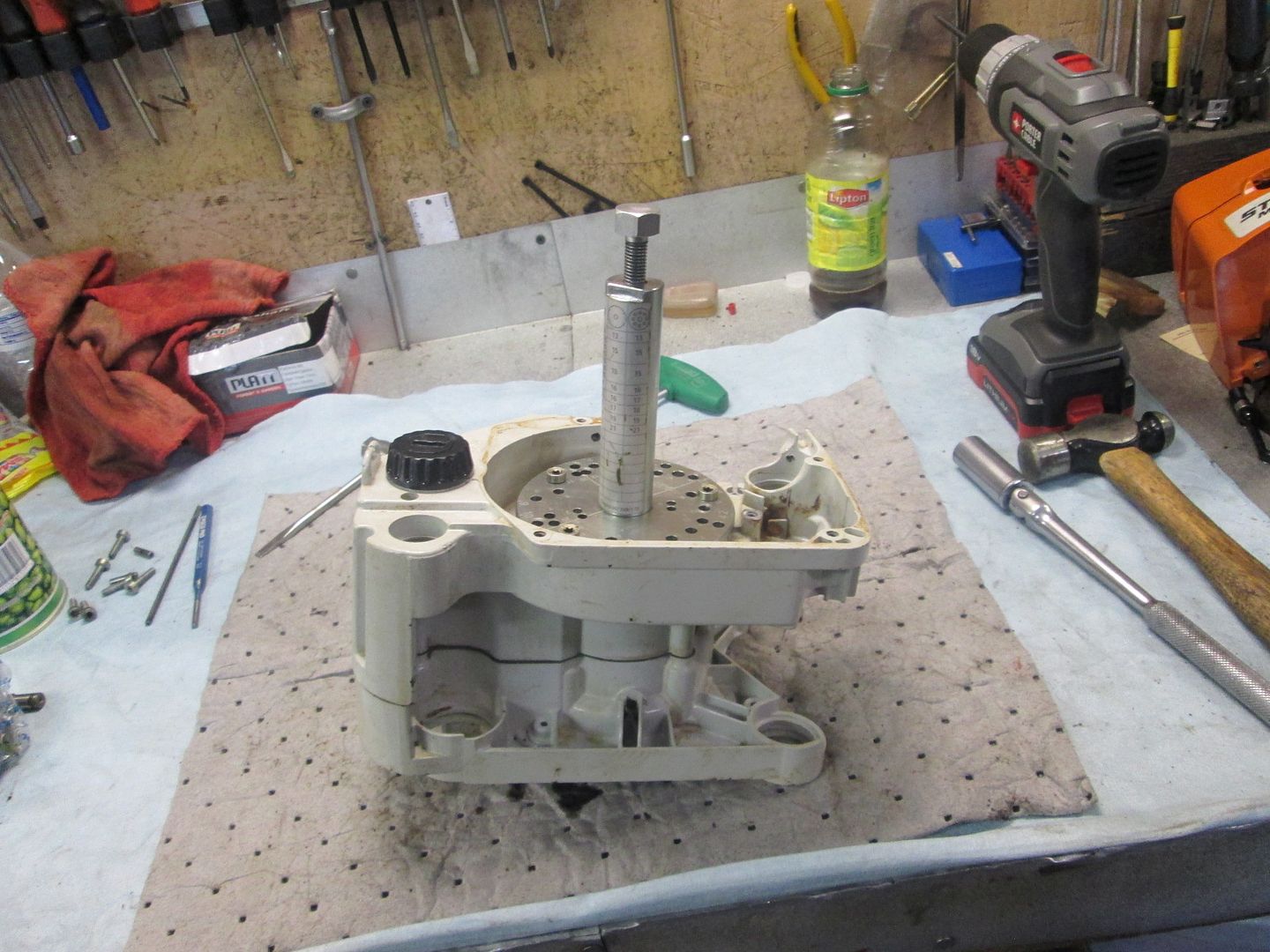

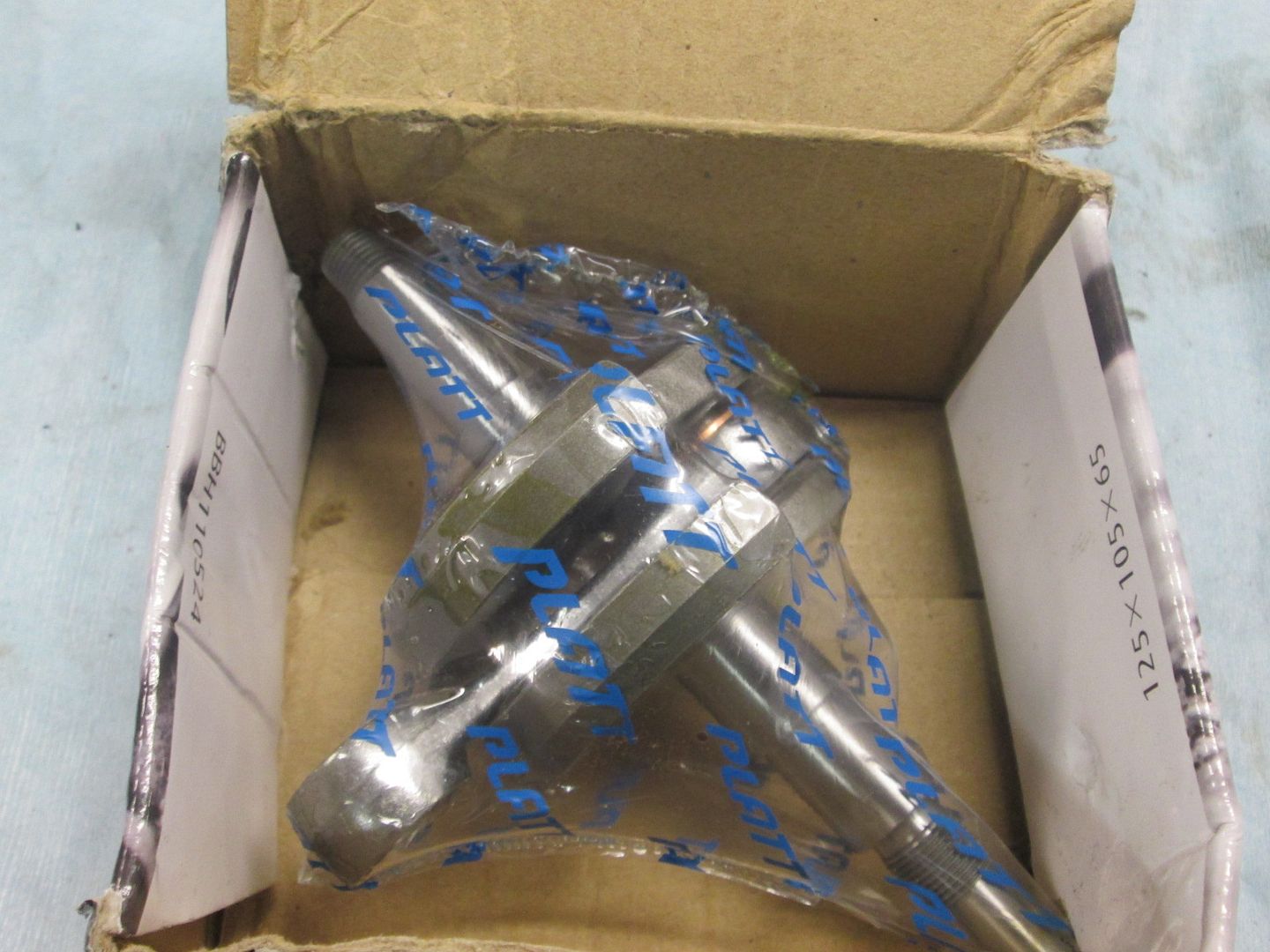

Using one of these.

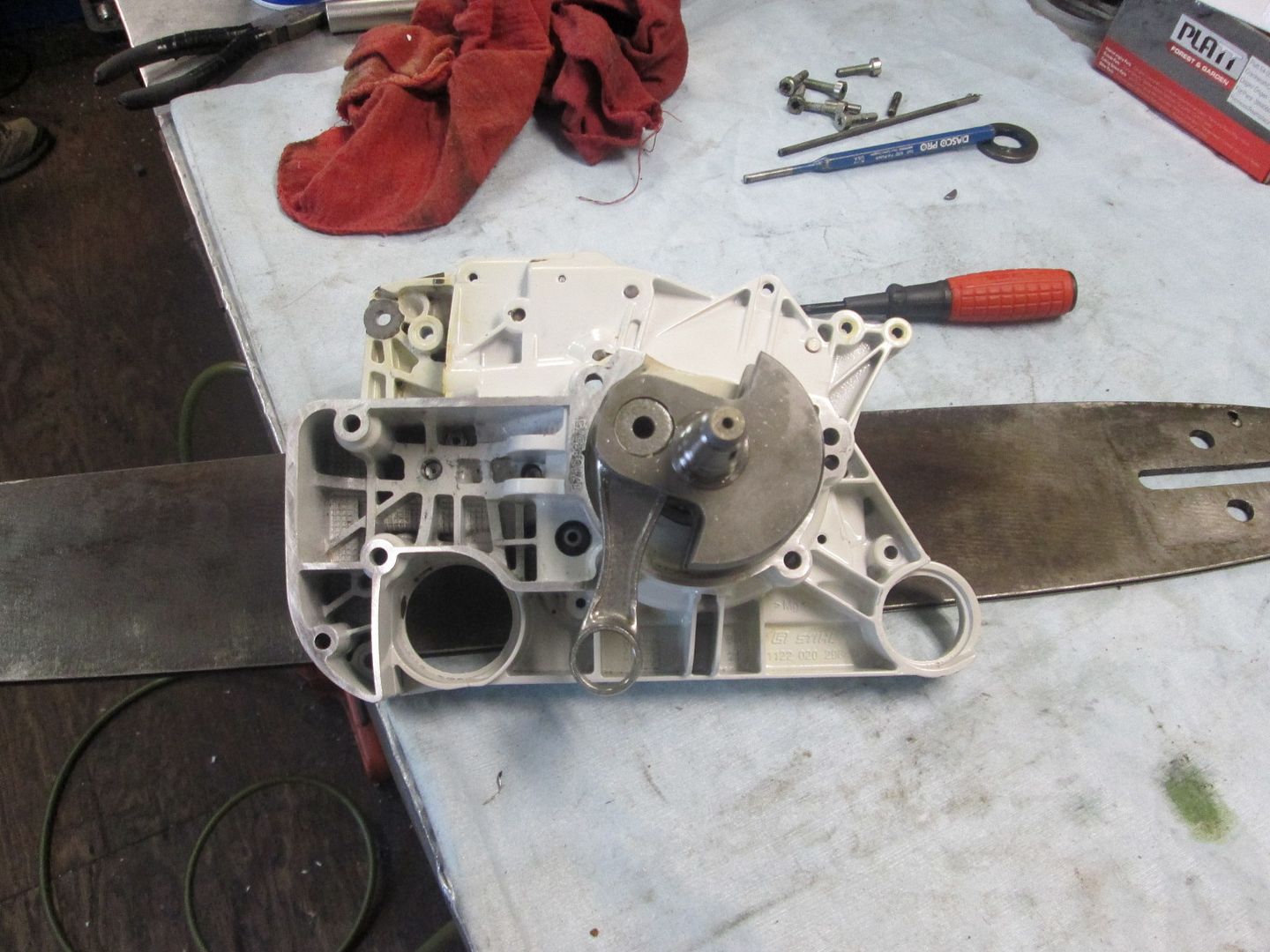

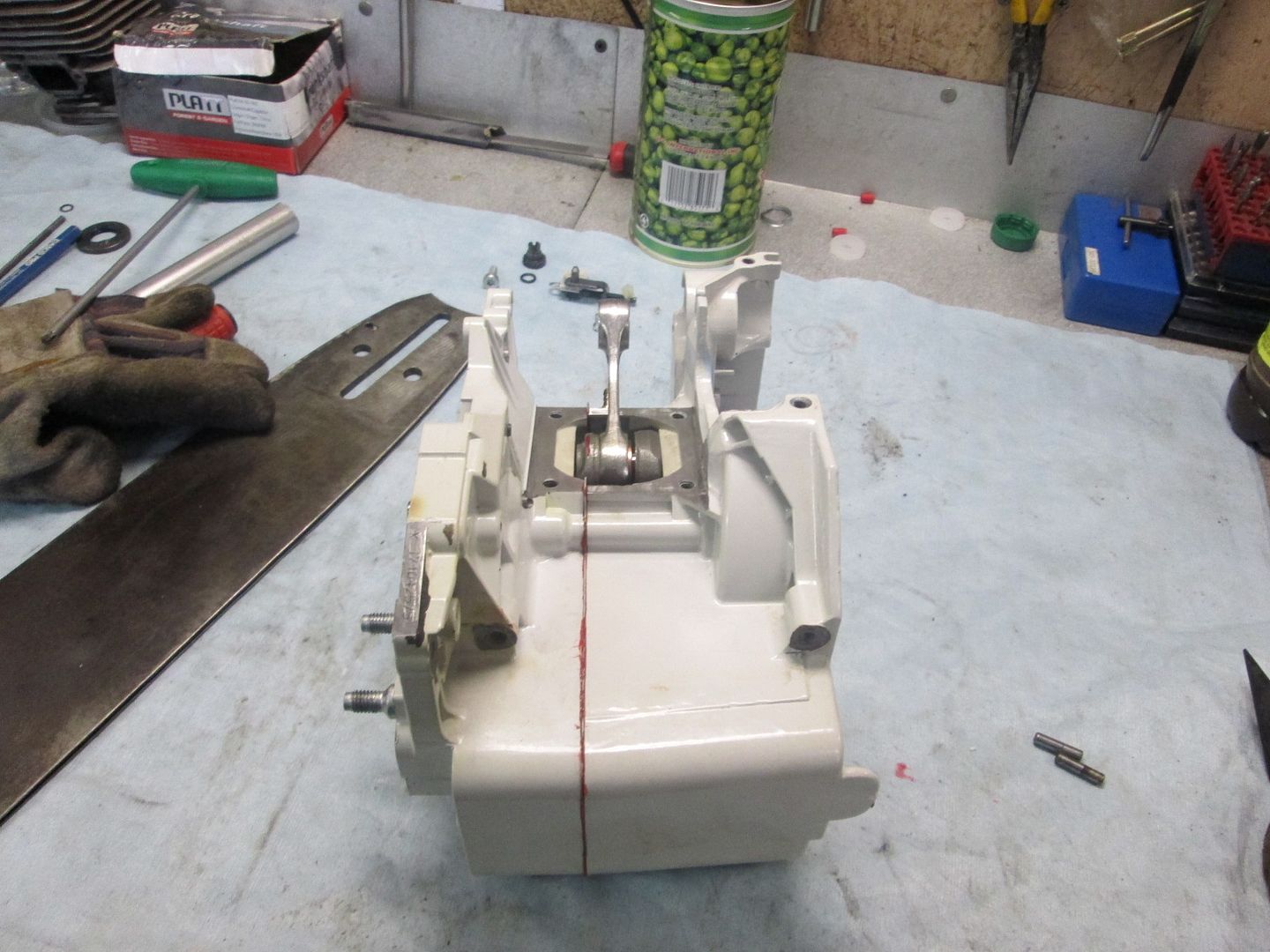

Weedeaterman sent the crank. Great fellers there....believe that.

Weedeatrerman

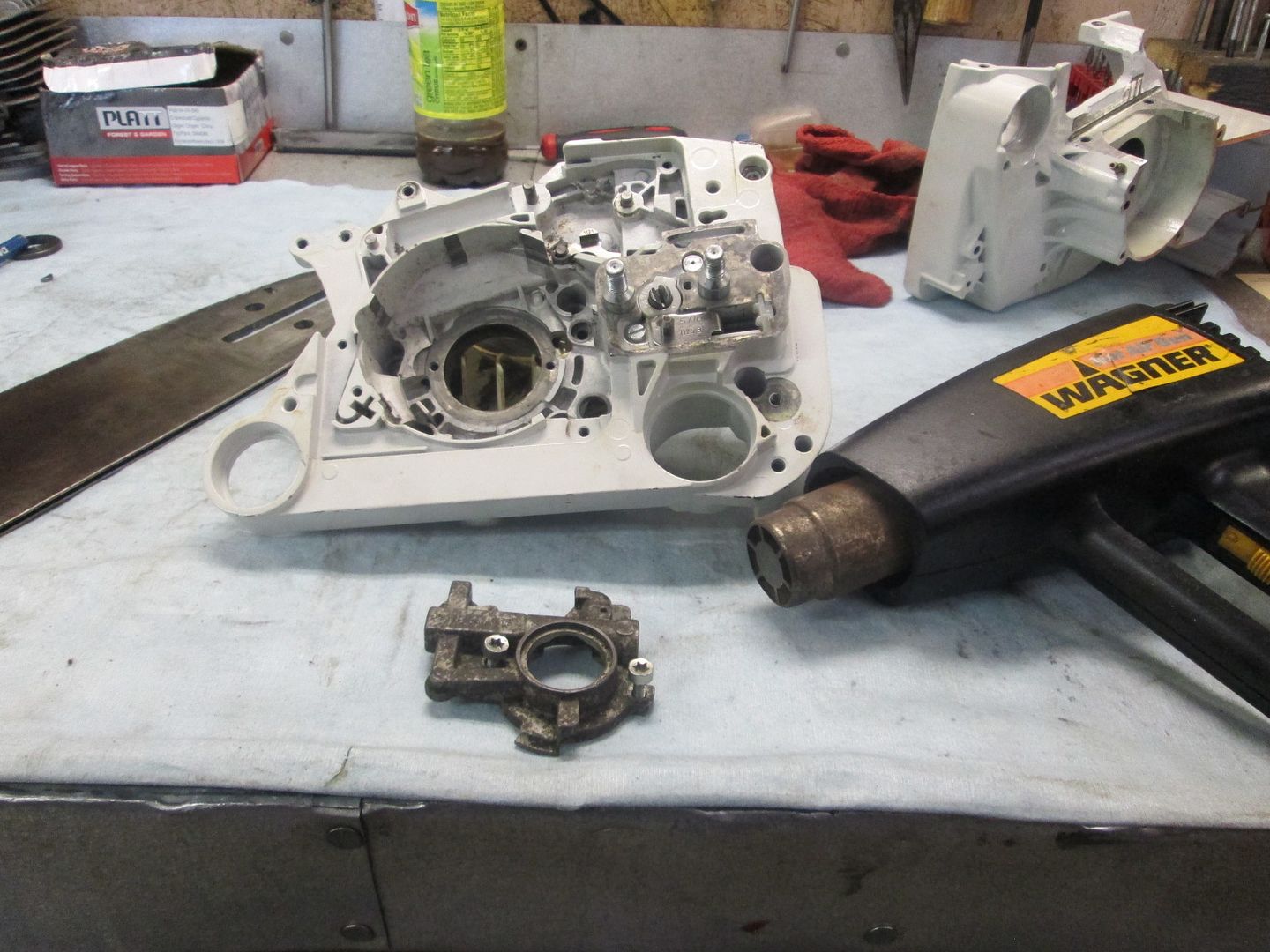

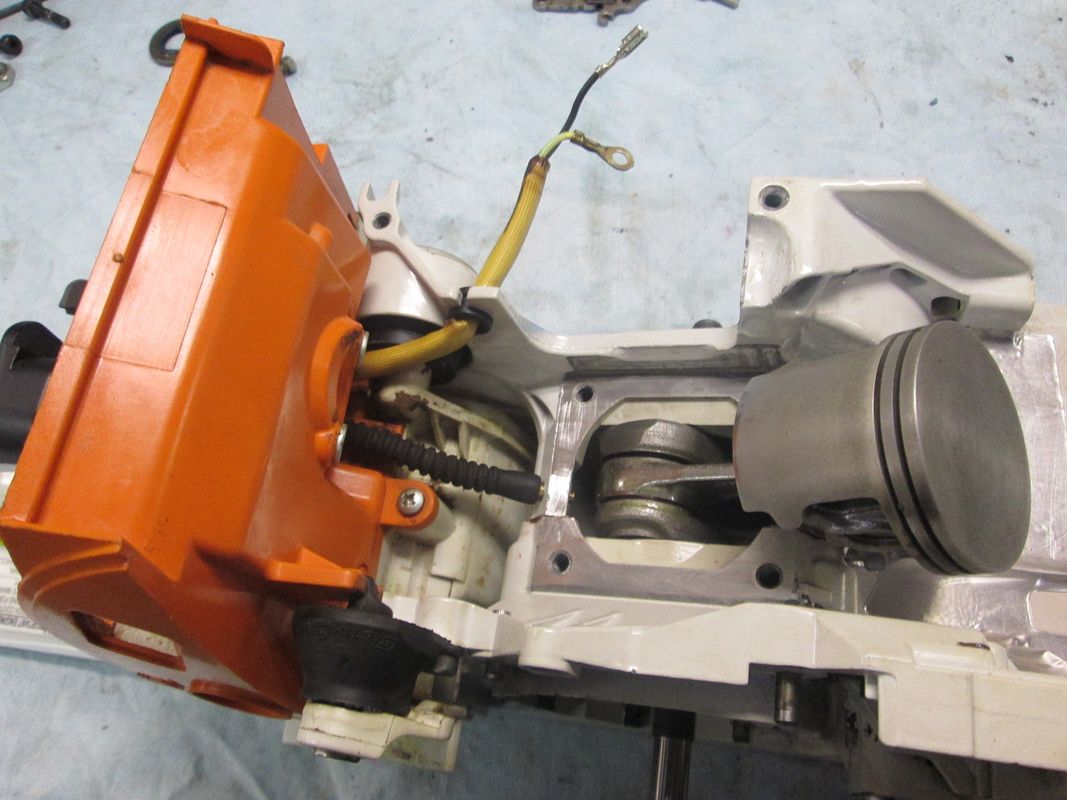

Brian is gonna mill with to try and kill it.

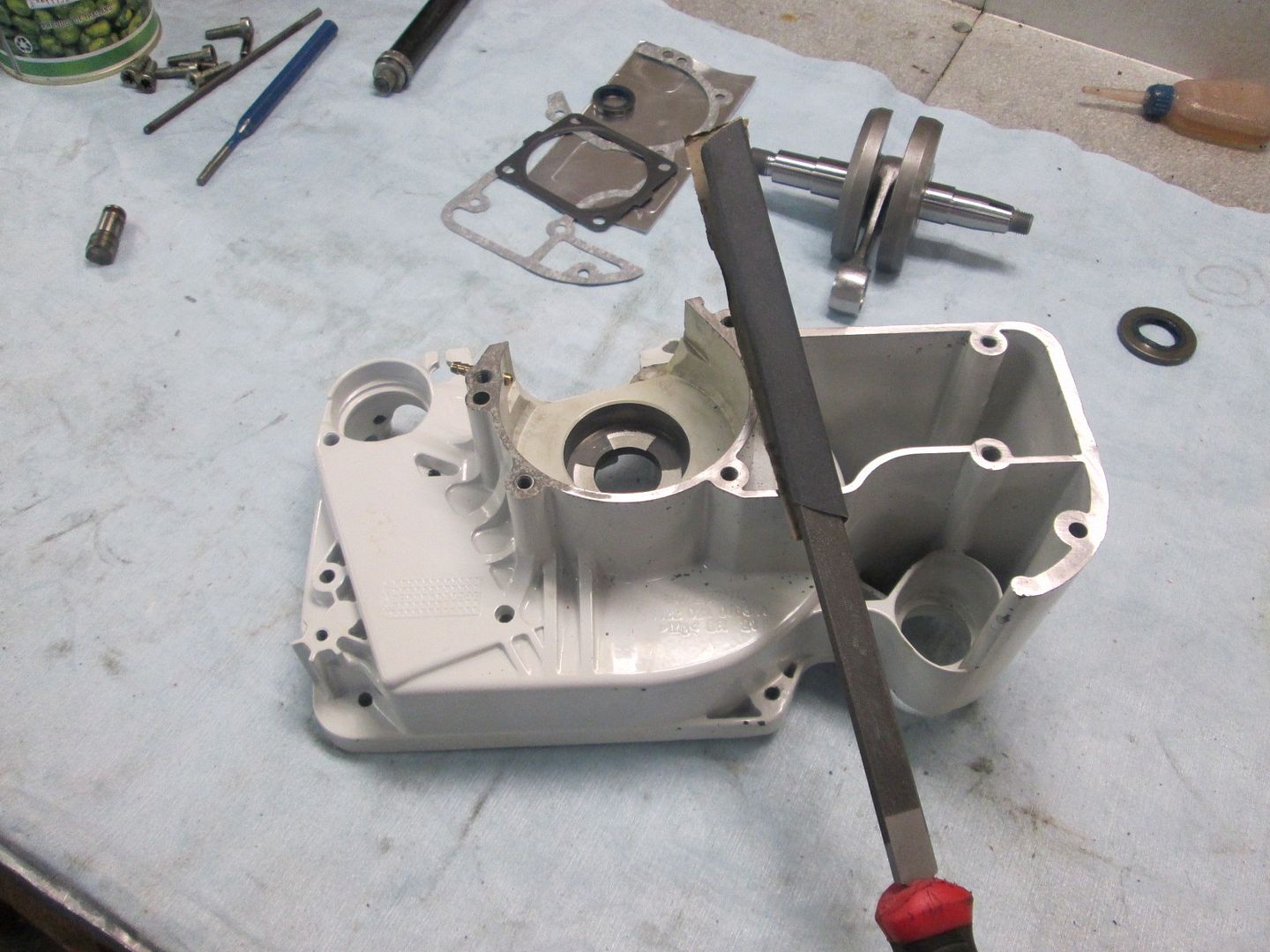

Oh........I'm porting it some too.

Brian killed it......but Jon is fixing it.

Using one of these.

Weedeaterman sent the crank. Great fellers there....believe that.

Weedeatrerman

Brian is gonna mill with to try and kill it.

Oh........I'm porting it some too.