SeanK

New Member

I'm not sure if this is the right forum for this question but here it goes.

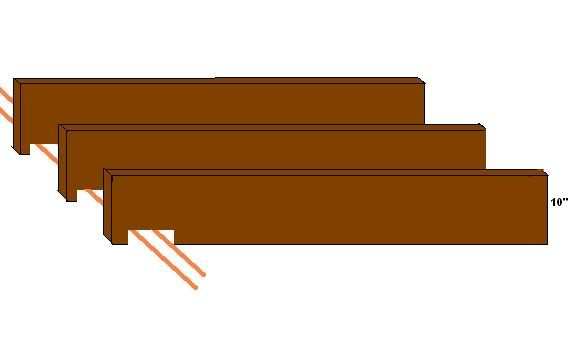

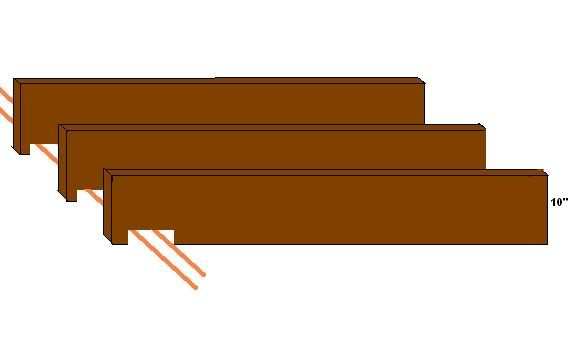

A plumber friend of mine who is re-piping a remodeled house has cut out a 2inch high, 5inch wide chunk out from a 2x10 overhead beam instead of drilling a hole in the middle of the beam in order to put the waterline through it. (please see picture)

He says he will put a metal plate under each of cut out section of the beam.

Would this pass the inspection? Thanks in advance.

A plumber friend of mine who is re-piping a remodeled house has cut out a 2inch high, 5inch wide chunk out from a 2x10 overhead beam instead of drilling a hole in the middle of the beam in order to put the waterline through it. (please see picture)

He says he will put a metal plate under each of cut out section of the beam.

Would this pass the inspection? Thanks in advance.