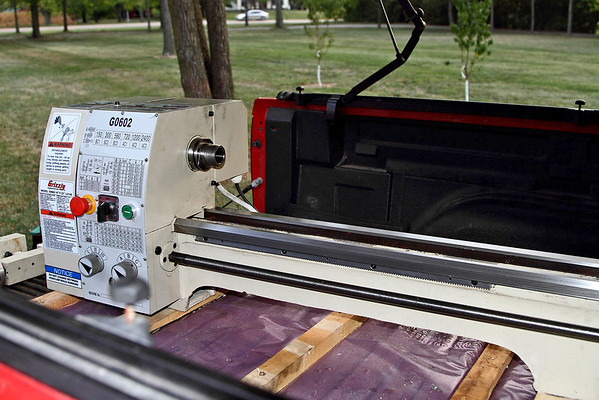

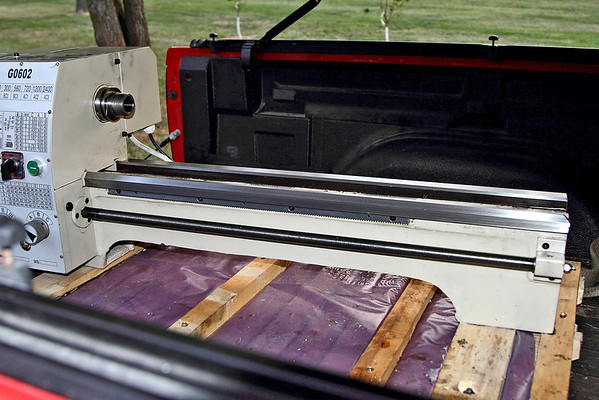

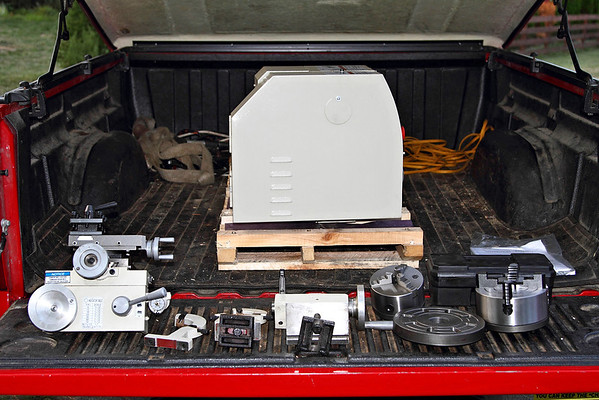

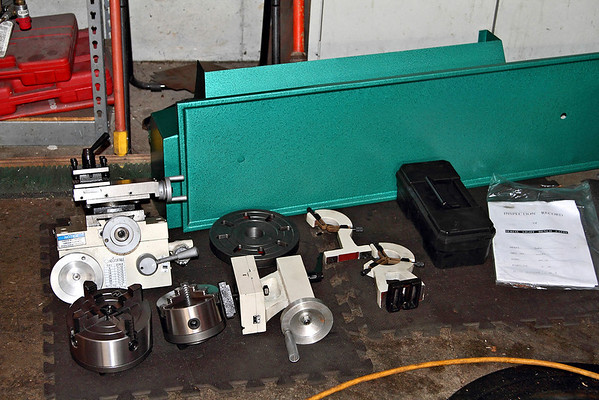

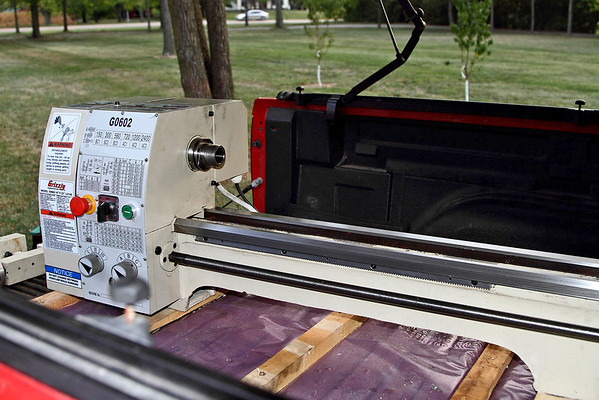

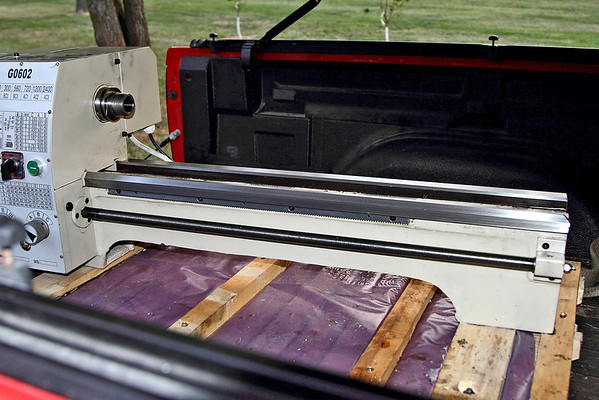

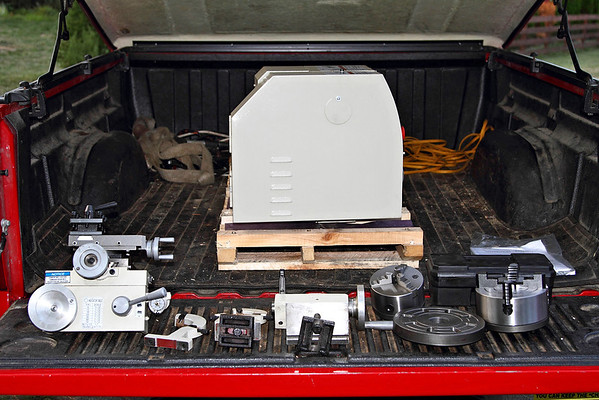

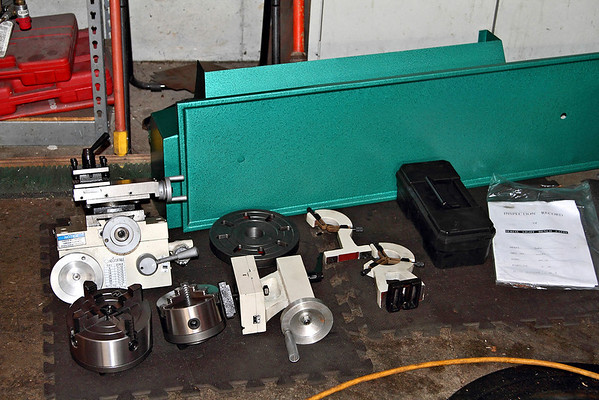

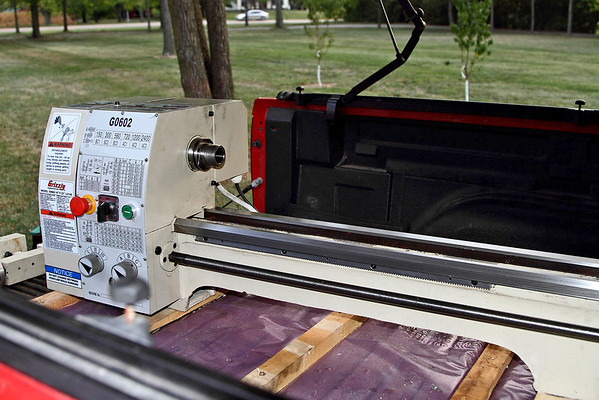

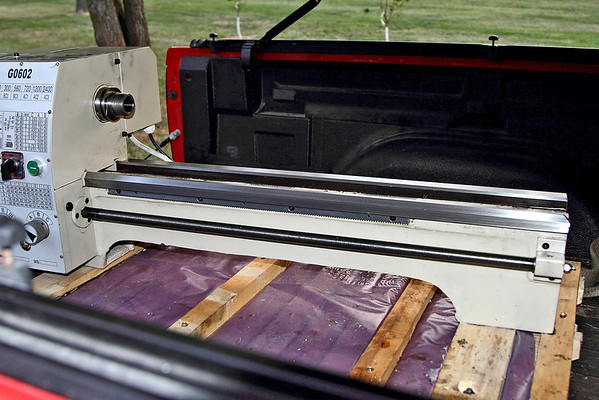

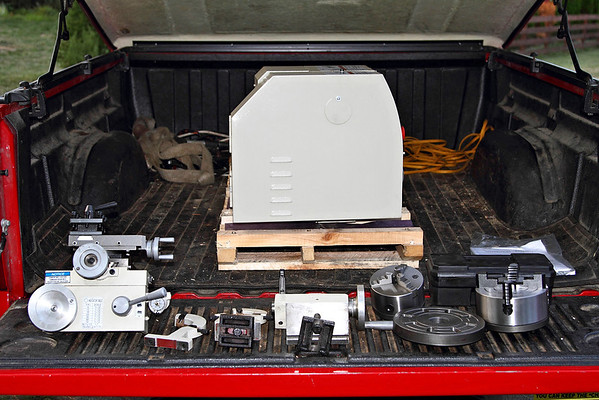

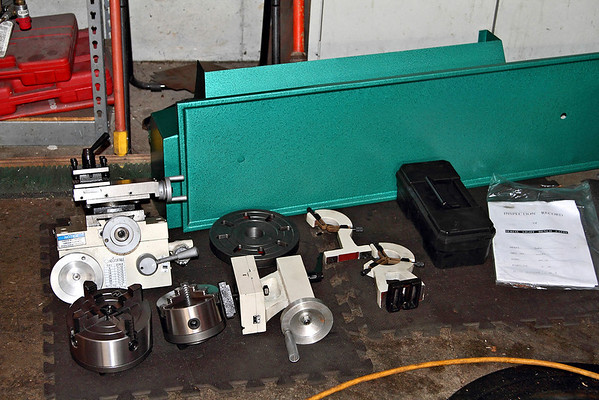

OK, I have a lathe now. What do I do with it, lol. I didn't take any pics of the crate and before I took everything off that I easily could. It should now be manageable to get into the basement. I'm guessing it should be down close to 300-325#.

If you get the headstock I'll get the tail..

I took a machinist class in trade school for two years. I used to love to run the lathes. I wish I would have stuck with it and tried to get a job doing it. Oh well, another career shot all to h@ll by the farm.

I took a machinist class in trade school for two years. I used to love to run the lathes. I wish I would have stuck with it and tried to get a job doing it. Oh well, another career shot all to h@ll by the farm.

How about non-detergent 30W in the gearcase for break-in oil?

Get some WAY oil.

Can this oil be bought locally? If not, where's a good place to order it?

always keep the tailstock hole, plugged (dead center is handy, and least in your way)

and Always double check it for *any* chips or debris

before popping in the next drill bit, center, chuck etc.

Anything gets pressed in there craters up a lump and then tools won't hold, like the flywheel taper cleanliness issue.

drills spinning will grab and bend, twist workpieces out of the chuck (damage to work then)

keep your quill retracted when it's not in use helps with keeping that part clean.

Always clean the ways before moving the tailstock, chips or dirt crunched under the t'stock

makes a lump that lifts the saddle,as it pass over and makes lumps or grooves in the work.

That is what was used in mine. Gamet bearings.....

HMMMMM......... Colchester, I presume

Steve

Enter your email address to join: