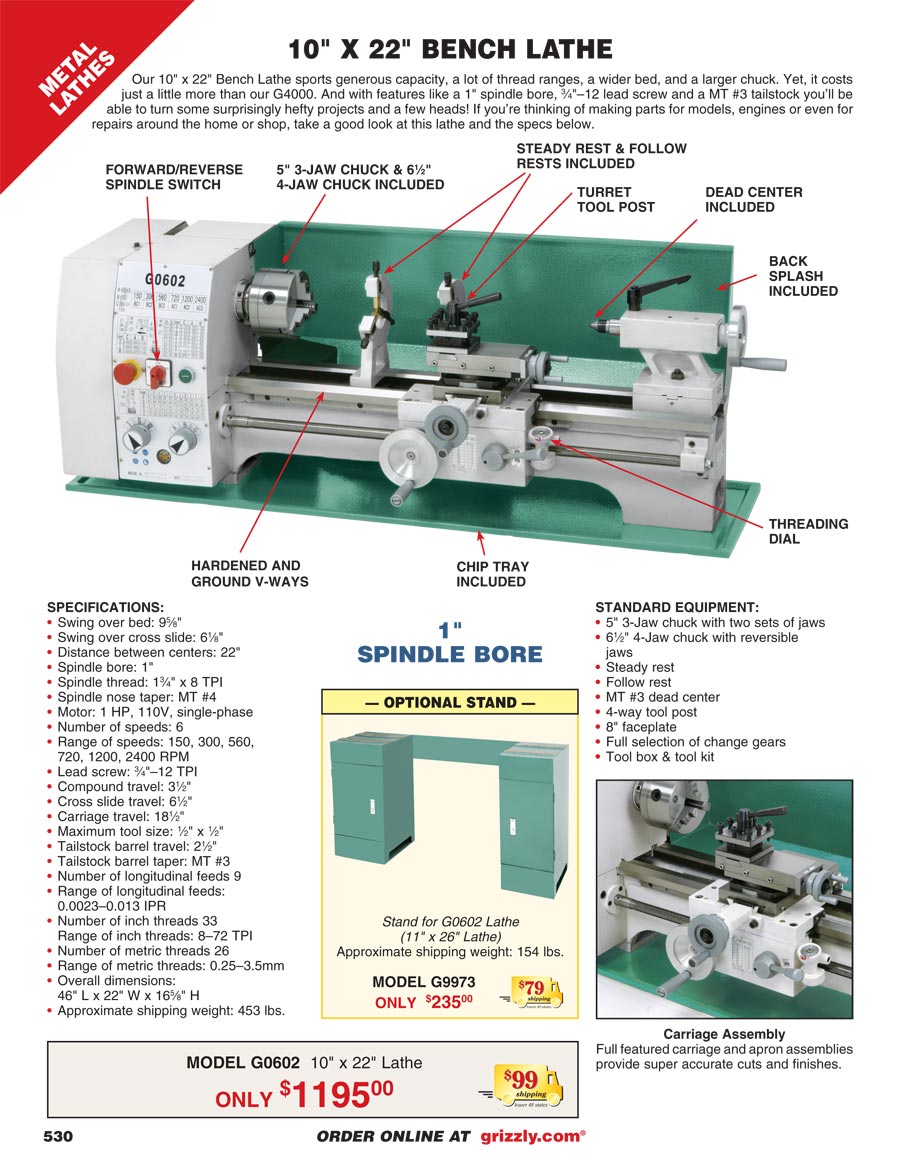

I finally made a decision and bought a lathe this evening. I decided to go new and went with a Grizzly G0602 10x22. The reviews on it are great and it's a heavy weight at 453# shipping weight. It's a much better value than the G4000, at only a couple hundred more dollars. The next size up 11" models didn't get the rave reviews this one did. I also considered the Lathemaster lathes, but their 9x30 looked to be less machine in most areas.

Yes, I'd love to have a nice heavy American made machine. But, I thought it wiser to keep it simple and start with a new machine. I won't know what I really prefer in a machine until I start using one. This lathe will do everything, and more, that I need it to do. Buying new removes a lot of variables that I don't care to deal with, or have the knowledge to, at this point.

I'm super excited to have this new tool coming. I have a hunch that I'll wonder how I ever got along without it.

http://cdn0.grizzly.com/catalog/2012/main/530.jpg

G0602 10" x 22" Bench Top Metal Lathe

you.

you. you.

you.