mheim1

Addicted to ArboristSite

Looking for opinions:

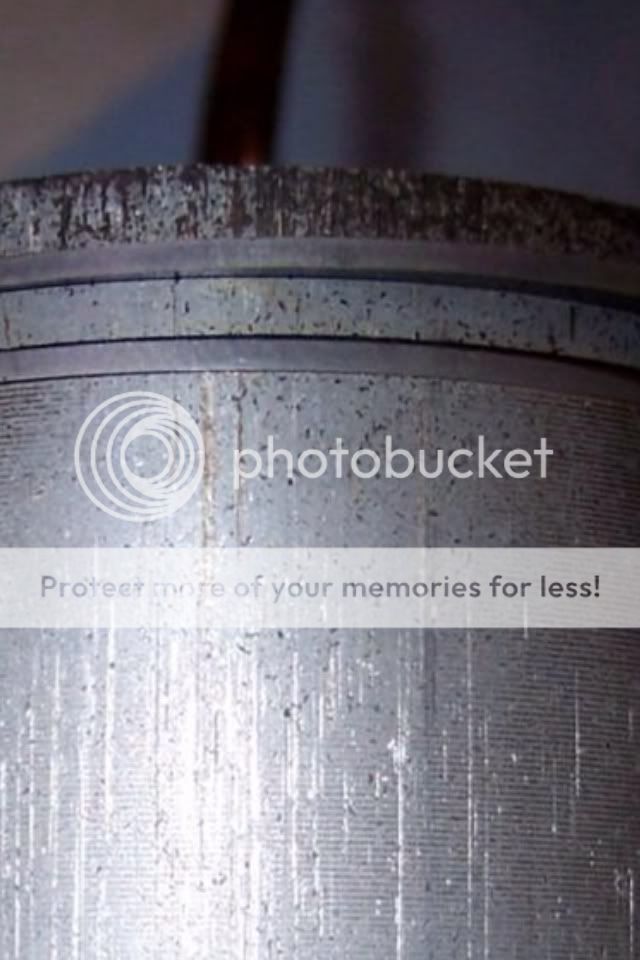

Stihl 066, personal saw (might use it twice a year just to cut the big logs), 135psi compression, cylinder looks good.

I have it apart already just for a cleaning and rubber replacement and wondering if I should just put some new rings on it, or a Meteor piston or just put it back together?

Appreciate thoughts.

Thanks.

View attachment 214265

View attachment 214266

And apparently, I haven't posted pictures in a while, as I can't seem to figure out where that little 'mountain looking thing' went. Sorry about that.

Stihl 066, personal saw (might use it twice a year just to cut the big logs), 135psi compression, cylinder looks good.

I have it apart already just for a cleaning and rubber replacement and wondering if I should just put some new rings on it, or a Meteor piston or just put it back together?

Appreciate thoughts.

Thanks.

View attachment 214265

View attachment 214266

And apparently, I haven't posted pictures in a while, as I can't seem to figure out where that little 'mountain looking thing' went. Sorry about that.