AUSSIE1

Al.

- Joined

- Aug 25, 2006

- Messages

- 8,004

- Reaction score

- 1,979

Hmmm, It seems Dremel needs to step up to the plate and manufacture us chainsaw guys a special 90 degree tip for upper trans. LOL

I'm sure their 90 degree attachment would still be cheaper than a Foredom or CC Specialty setup.

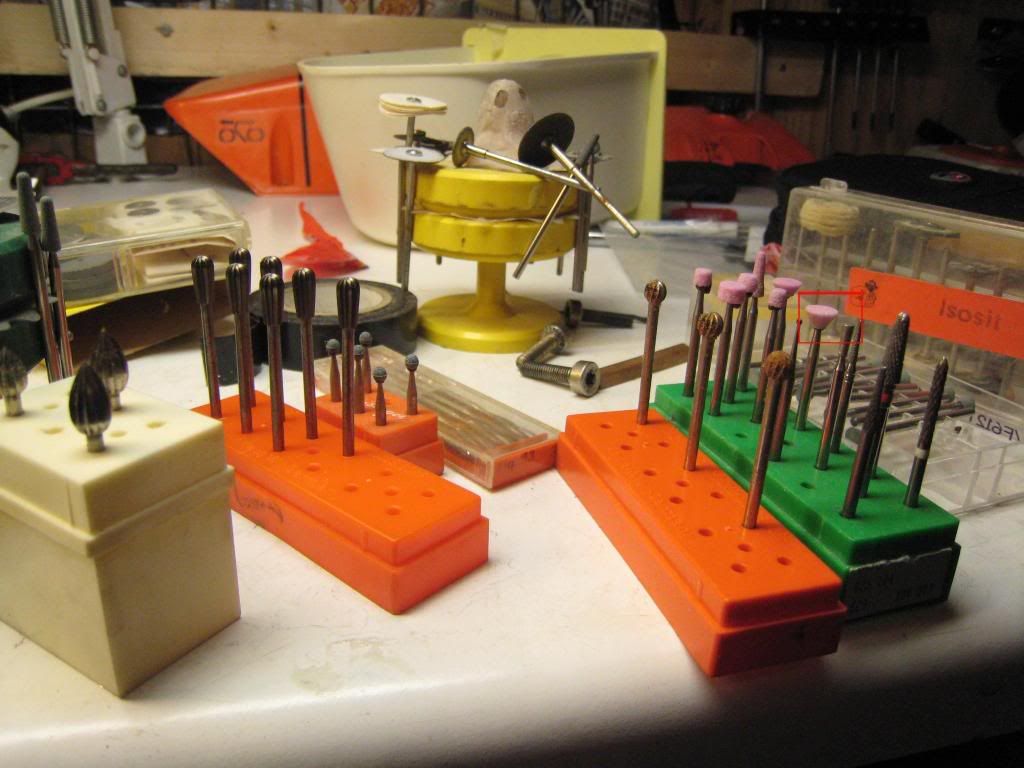

Cool, yeah they seem to have every burr a guy could ever want in there. I found that company in Welding Magazine.

Dremel makes a 90 degree attachment, but I think it's too big for small cylinders.

Exactly, their attachment is waaay too big. They need to make a smaller one for us.

And there is no reason why they couldn't.

The Dremel was made for fine work and then make an angle drive the size of something like 2"

Obviously not a market big enough for something that suits our requirements.

Last edited: