Work Saw Collector

GTG Coffee Maker

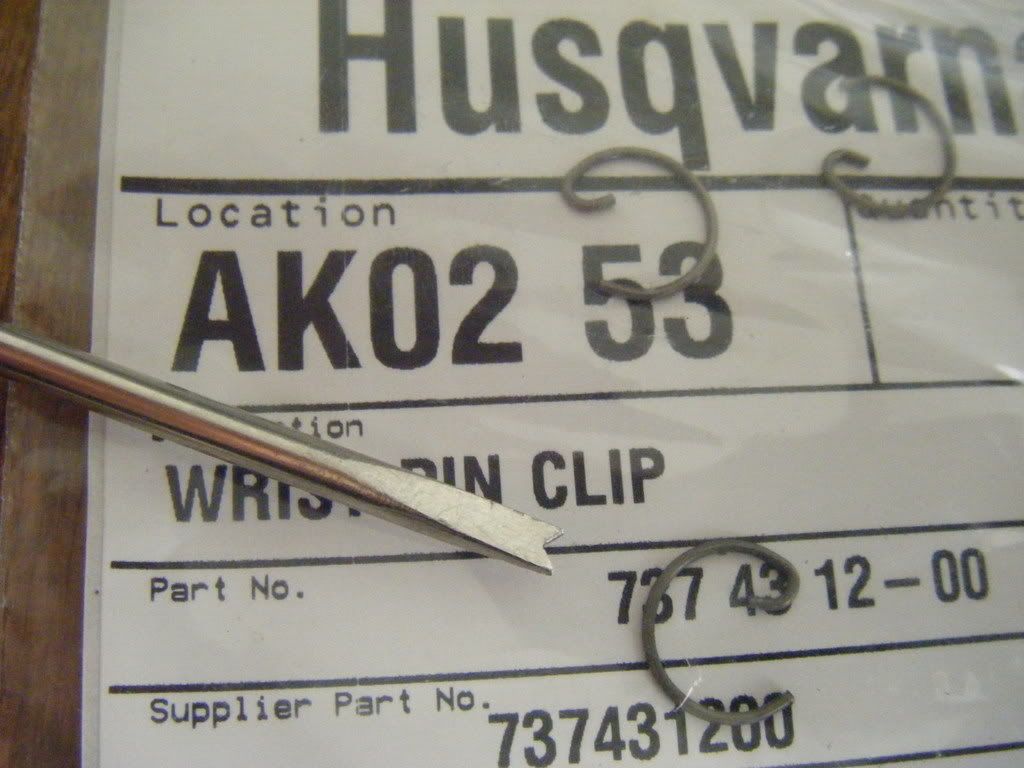

I need a class on them clips uninstall install any and all tips. I sent 3 flying across the shop sounded like they were running mack 1 when they left the saw.:hmm3grin2orange: There has got to be a better way than the way I'm doing it, start one end and work it around with a carb tuning screw driver.

The story if you care to read it. The fourth one I thought I shot into the lower end of the saw. I got into a fight with myself at this point. Listen here You SOB it is in the bottom end or it isn't none of this I think stuff. Stop yelling at me I going in the bathroom and locking the door untill you say your sorry. Take a samich with you it will be a long wait. :biggrin:

So I turn the saw upside down and bang it on the floor, rotate crank bang on it some more. I blow air in and around the crank wash it out with mix gas. I'm now sure its not in the lower end. I have both clips in it now. I'm just looking for a better way, Is there tools for install and uninstall?

The story if you care to read it. The fourth one I thought I shot into the lower end of the saw. I got into a fight with myself at this point. Listen here You SOB it is in the bottom end or it isn't none of this I think stuff. Stop yelling at me I going in the bathroom and locking the door untill you say your sorry. Take a samich with you it will be a long wait. :biggrin:

So I turn the saw upside down and bang it on the floor, rotate crank bang on it some more. I blow air in and around the crank wash it out with mix gas. I'm now sure its not in the lower end. I have both clips in it now. I'm just looking for a better way, Is there tools for install and uninstall?