Does anyone have a complete list of the grind angles for all the different chain? I found an Oregon list but it doesn't list the older styles nor- Stihl or Carlton or Windsor.

OK. Here goes:

Simple answer is' '

No'. Even more frustrating answer may be, '

It changes!' Best answer is,

'It's up to you.'

When I first started sharpening, I was obsessed with finding the

correct angles for

every chain. One of the frustrating things I found was that Oregon might spec

different angles for the

same chains on its package, in their grinder manual, and in a product spec sheet!!! An Oregon rep explained it to me (I'm paraphrasing here): they make chains for literally millions of potential users, in different countries, doing different types of cutting, with hundreds of species of trees, using different saws, etc., etc., etc. So their

recommendations are based on an assumed '

average' user doing '

typical' cutting. Sometimes they change their recommendations. The

specific,

optimal angles would vary with each of those factors. I was advised that what was important was consistency; getting the same angles on each cutter, for a smooth cutting chain.

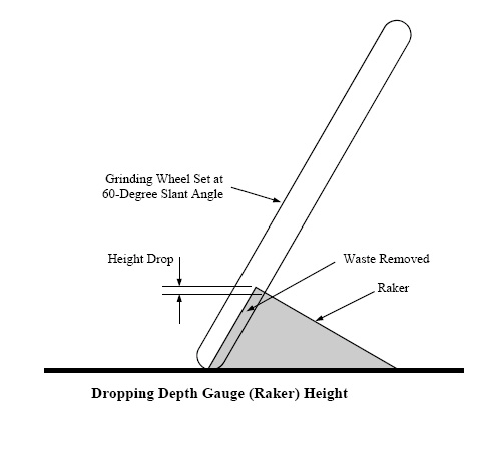

My local saw shop guy (60 years in the business?) always sharpened every chain at 30°/60°/0°, so I started there. In the last few years, Oregon has recommended 55° on most of their chains to the point where this angle is highlighted on their new grinders (just like it was on the speedometers of cars for awhile!).

Oregon says that a 10° down angle absolutely makes a difference under test conditions, on most of their chains, and have expanded that recommendation to more of their chains over the years. But some grinders, and some file guides, do not accommodate the 'down angle', so I avoided that when sharpening chains for others. Going back-and-forth between 0° and 10° down angles wastes a lot of cutter life.

So,

my personal, default angle, for

my chains, is now 30°/55°/0° (except when using mini-grinders that are fixed at 60°!). I never know what I will be cutting, so I stick with the 30°.

This Is America! YOU get to choose!

1) Pick a 'standard/default' set of nstueve angles and stand proud with those!,

OR

2) Try to figure out what the chain was sharpened at the last time, and match that,

OR

3) Ask each customer what they want - you can't go wrong there, and most will probably ask what your default angles are anyway.

The recs for some discontinued chains, including file sizes, can sometimes be found in older copies of STIHL or Oregon manuals, but these chains are less common.

You can add these references to those already posted:

- Tri-Link lists file sizes:

http://www.trilinksawchain.com/downloads/TriLinkProductKnowledgeGuide.pdf

- Pferd lists file sizes and general stuff:

http://www.pferdusa.com/info/PDF/Chain_Saw_File_Field_Guide.pdf

- Carlton (older) attached.

- Tecomec Jolly Grinder (old) attached (print pages and line them up side-by-side).

-

Oregon 511A manual attached.

Philbert