I bought a non running 266 for 30 bucks, all it needed to get running again was adjusting the idle and fixing a broken throttle linkage.

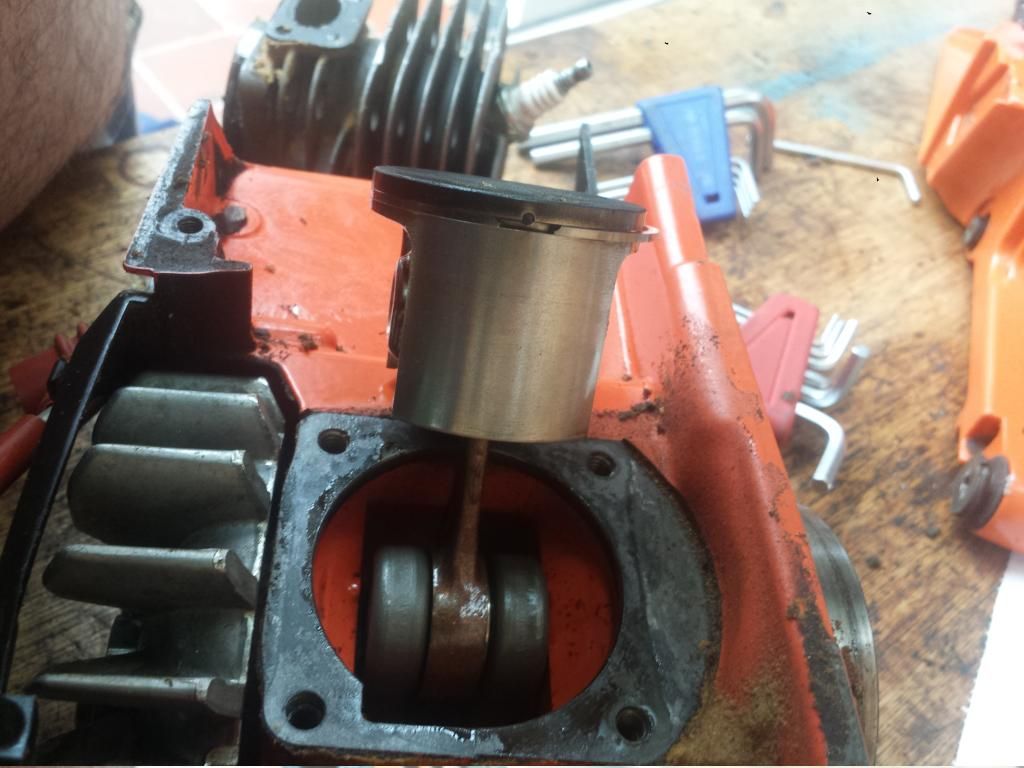

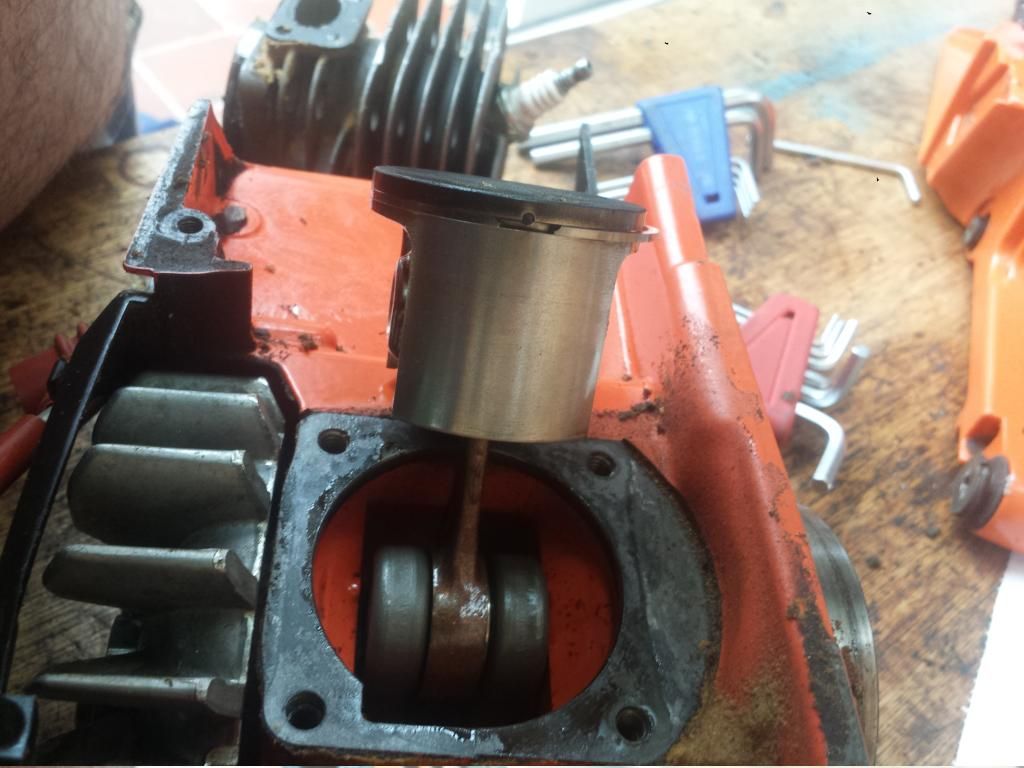

Now i would like to mod it just for the fun of it. A bit more than a worksaw, but not a competition saw either. I added some pics of the saw taken apart. Cylinder and piston look just fine, carb is around 18.5mm.

I would like to get some pointers on how much to enlarge the ports, and how to modd the mufler. If there are any good threads to look at please let me know.

Thanx!

Now i would like to mod it just for the fun of it. A bit more than a worksaw, but not a competition saw either. I added some pics of the saw taken apart. Cylinder and piston look just fine, carb is around 18.5mm.

I would like to get some pointers on how much to enlarge the ports, and how to modd the mufler. If there are any good threads to look at please let me know.

Thanx!