You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

MS461 Giveaway Saw Build Thread

- Thread starter Mastermind

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Great job there Randy.......always learn a little each time you do a thread......

Very impressive. Love the funny talkin' videos. Wish I had $250...

Mastermind

Work Saw Specialist

Do you hand sand, or put it on that sanding deal you use for cleaning up aluminum transfer on cylinders?

I've got different sizes of split mandrels that I've made....I use a shorter one for the port work.

Great job there Randy.......always learn a little each time you do a thread......

Thank you Randy. Sir Chef.

Very impressive. Love the funny talkin' videos. Wish I had $250...

I'll get slammed with work after this thread, I always do....of course, that's a good thing.

OK, the jug is in the ultrasonic tank......in a few minutes I'll post pics of the finished product.

fastLeo151

Addicted to ArboristSite

How often do you go outside your recipe papers? Or do you generally stick to building them exactly the same

Mastermind

Work Saw Specialist

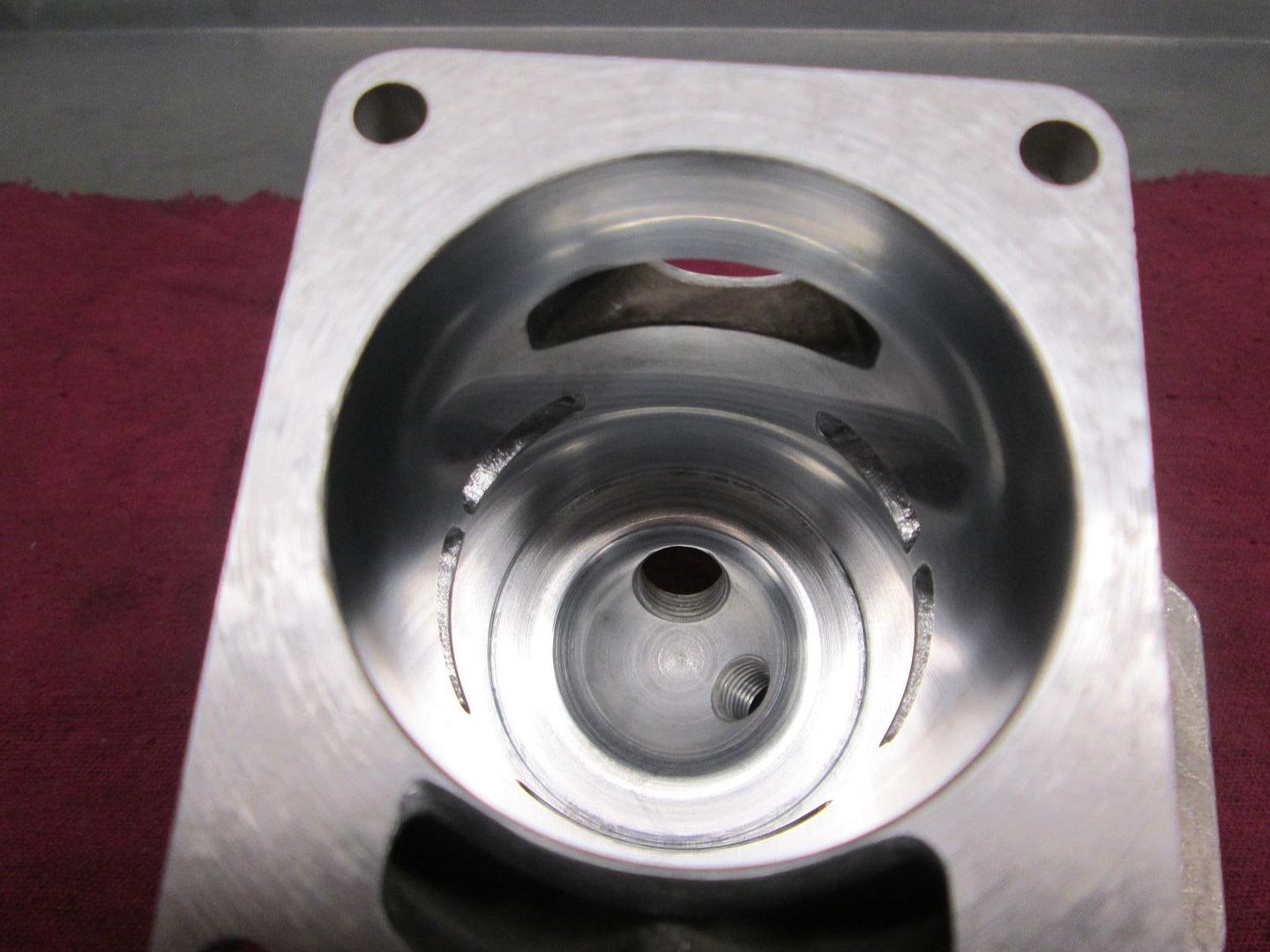

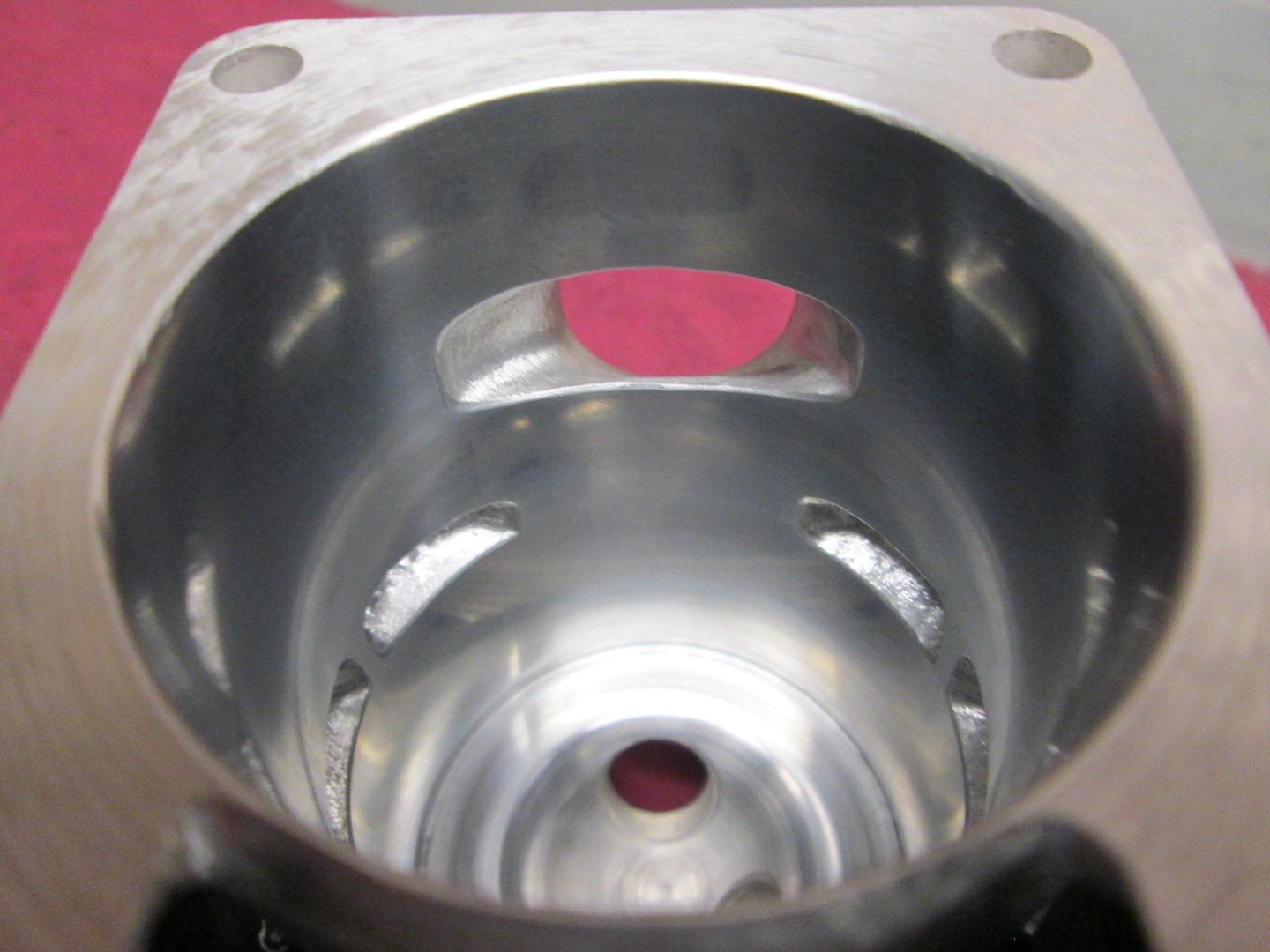

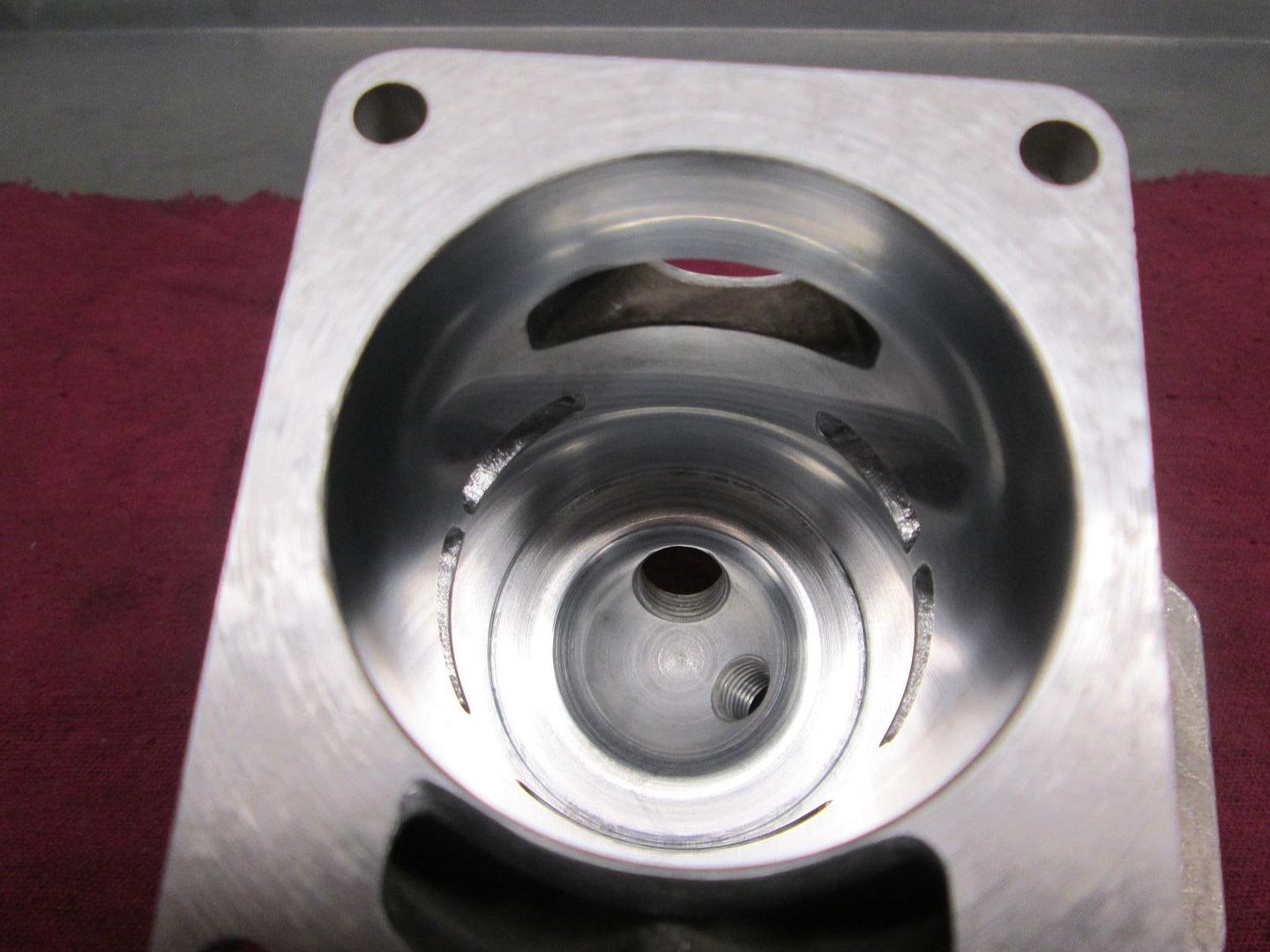

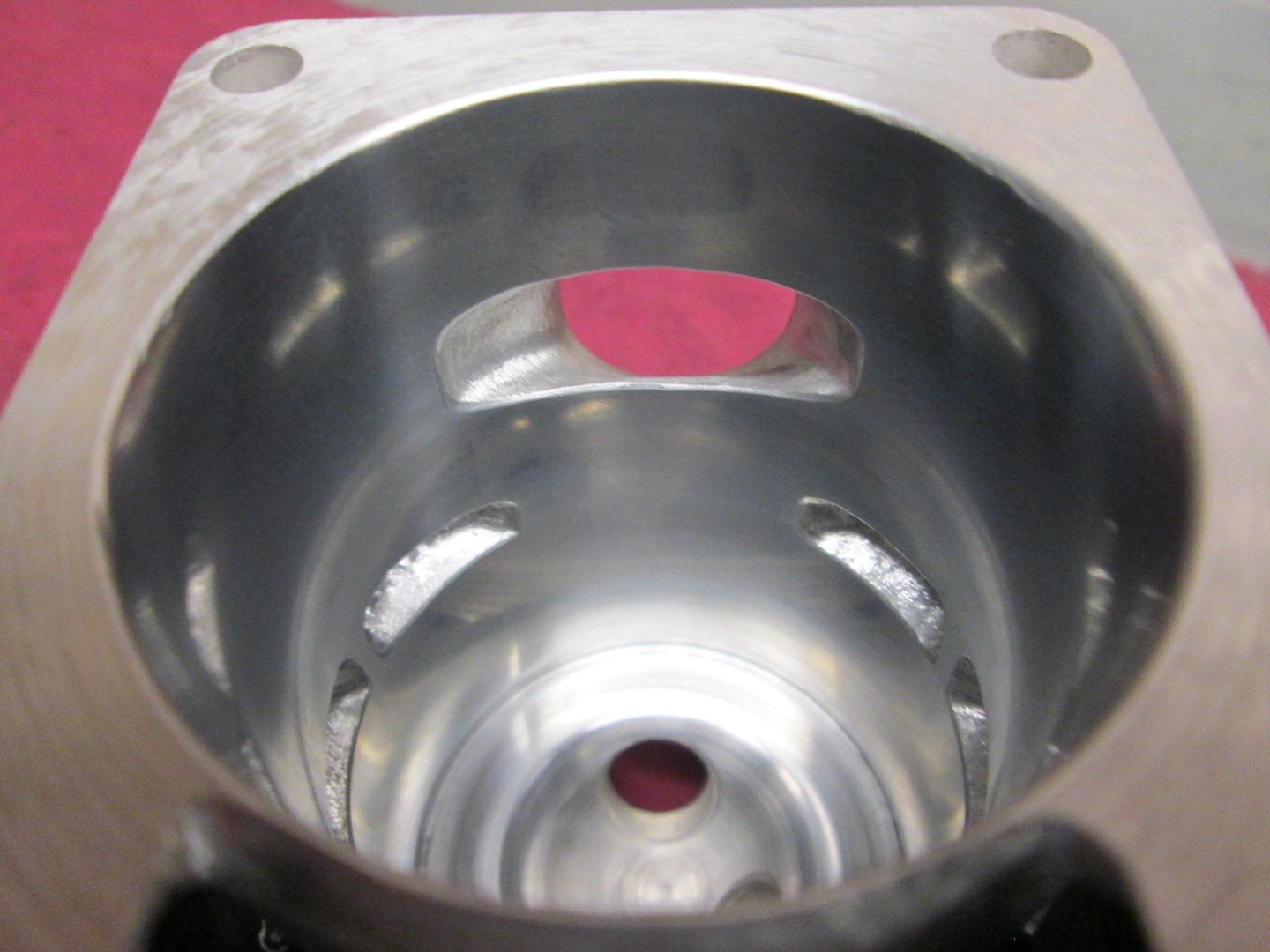

Now the port work is finished, and the jug is ready to put back on the engine. I feel like I've done a good job on the porting when it's not obvious what all I've done. I had a fairly well known (but not very well liked) saw builder tell me that he had one of my engines apart, and that all he could see was that I had shined up a few things in it. I then told him that I also had been in one of his......and that it looked like something my grandson would do with a burr. That bastard hung up on me.

In these pictures notice that I've rounded the edge of the squish band here. You should also be able to see a small bevel around the port edges.

In these pictures notice that I've rounded the edge of the squish band here. You should also be able to see a small bevel around the port edges.

splitpost

Nothing but 32:1

crane

Addicted to ArboristSite

Wicked thread Randy. The pics are awesome!!

Some lucky winner will be able to pile wood chips at their feet all day, kick those same feet up that night and see how it was all done, right here.........

Some lucky winner will be able to pile wood chips at their feet all day, kick those same feet up that night and see how it was all done, right here.........

Please ask any questions you want, no matter how elementary you may think they are.

Does the wasabi pea residue make the saw run faster?

Mastermind

Work Saw Specialist

How often do you go outside your recipe papers? Or do you generally stick to building them exactly the same

That's a good question Andrew. I'm glad you brought that up.

When a model is something new, like this one was last year, I'll stay close to the original timing numbers. I'll add compression, set the squish in the .025" range, try some ignition timing advance, etc. Then when I put a few tanks thru the saw, I'll try to decide if it needs more exhaust, transfer, intake, and so forth. After that first saw, then I'll vary just the transfer, or intake timing a couple of degrees to see if it makes a difference. I'll vary a few degrees over ten - twelve saws, trying a little different numbers. When I see that I've gotten that model running the best I can make it, I'll stick with those numbers.

My worst fear is making a turd. It would really look bad if a couple of guys with the same saw, built by the same builder showed up at a GTG, swapped on new chains and one saw just waxed the other one's ass. That's why I'll only made small changes over many saws.....

Mastermind

Work Saw Specialist

Does the wasabi pea residue make the saw run faster?

Well duh. Wasabi Peas are like Nitromethane to a two smoker.

Another vote for an outstanding build thread. One of the best by far. For every picture/video posted, all I could think was,,,oh I would screw that up so fast. Worth every penny of the $250 if you ask me.

fastLeo151

Addicted to ArboristSite

Now the port work is finished, and the jug is ready to put back on the engine. I feel like I've done a good job on the porting when it's not obvious what all I've done. I had a fairly well known (but not very well liked) saw builder tell me that he had one of my engines apart, and that all he could see was that I had shined up a few things in it. I then told him that I also had been in one of his......and that it looked like something my grandson would do with a burr. That bastard hung up on me

I'm in the mood to nut punch some one....point em out

Mastermind

Work Saw Specialist

Thanks for the sanding reply. This is one of the best threads on porting I have read. I know how much time it takes to get these photos and videos done. I surely appreciate it.

You are welcome Doug. There are a lot of guys that want to port their own saws.......I understand that, and am happy to help those guys see how I approach it. A lot of people say I shouldn't show so much of what I do, that my competition will take that information and use it to build saws just like the ones I build, and then I'd lose any edge I may have. To that I say, if anyone else is willing to put this much effort into building chainsaw engines, then they deserve to get plenty of work. This ain't a real easy gig....

Last edited:

Beautiful work as always Randy. People can look at your pictures but they ain't gonna be able to copy your work. The ones with that much talent are going to do their own thing and take a few cues from you and others...which only makes everyone better in the end.

Frank Boyer

Addicted to ArboristSite

Extremely nice work.

fin460

Ham Fisted

Randy these saw build threads are better than sex!,... well atleast it lasts longer lol

D

Deleted member 116684

Guest

finally got around to checking on this thread. There are just not enough hours in the day! I'm loving the thread. Thanks so much for posting all the pics. Also, its a joy to help someone out in a tough time. And I might even win a saw. It's a win-win situation, so how do I donate?

Similar threads

- Replies

- 1

- Views

- 423

- Replies

- 10

- Views

- 802