I've had my OWB online now for 15 years and have had a problem creep up on me. I have too much heat. LOL It started this year the opposite when I noticed on extreme cold days it wasn't heating as good as it used to. I attributed it a pump cartridge that had gone out years ago and the impeller had broken into pieces and were sent on down the line to the heat exchanger plate. I figured this year I would take it off and flush it because I though it might be plugging it some. With these warm temps this year, the house was staying warmer now even though the thermostat is set at 68. Lat night it was 83 degrees in the house and decided something is really wrong here.

I went down thinking the 3 way zone valve had stuck open as it was still sending heat out to the house. Used the manual lever and moved fine. Took the head off and plunger moves up and down freely. I always put a few drips of oil on it at the start of the season. Put it all back and still the same.

At this point I'll explain my system to give a better idea of what I have.

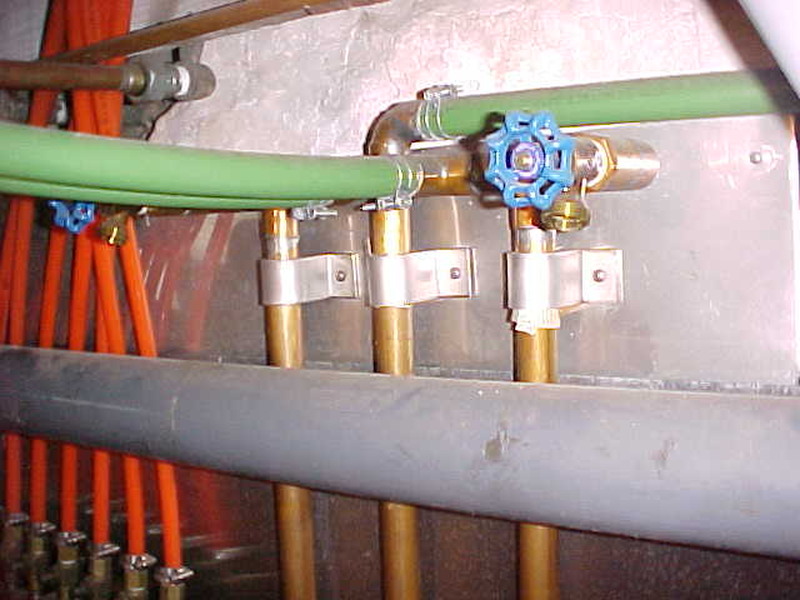

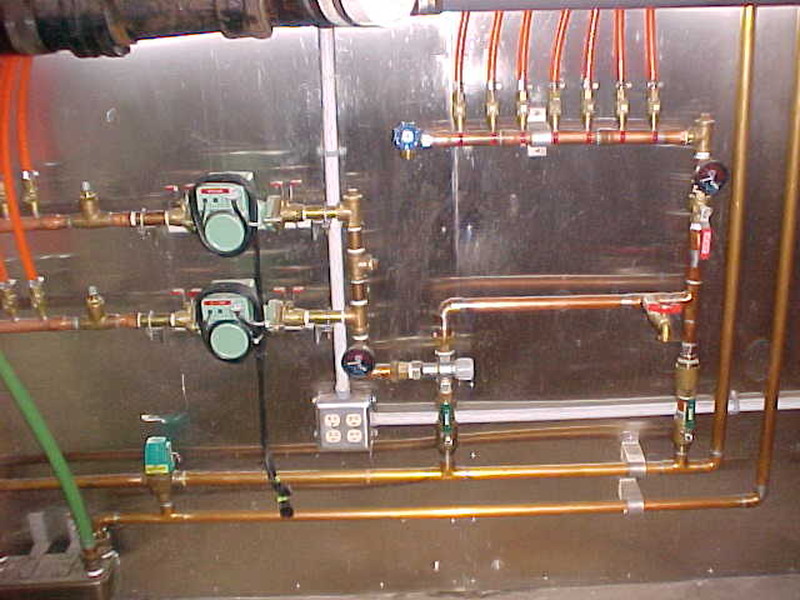

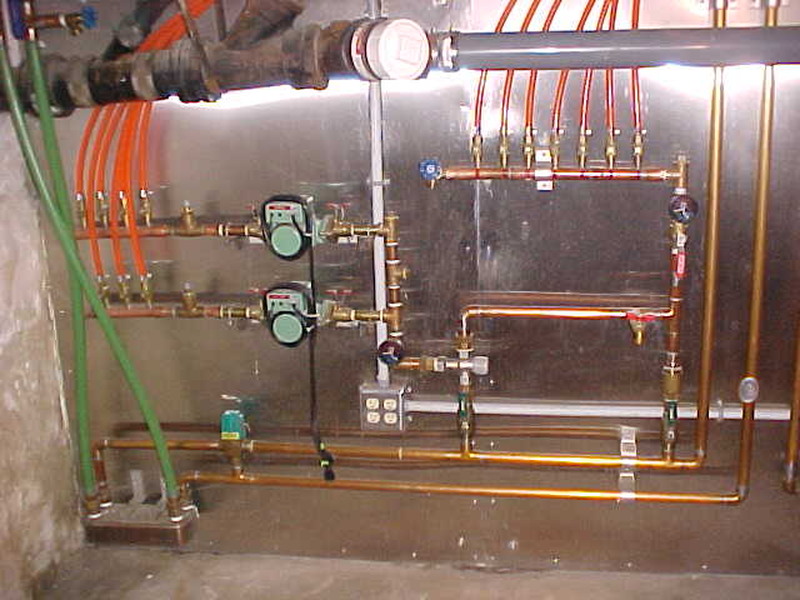

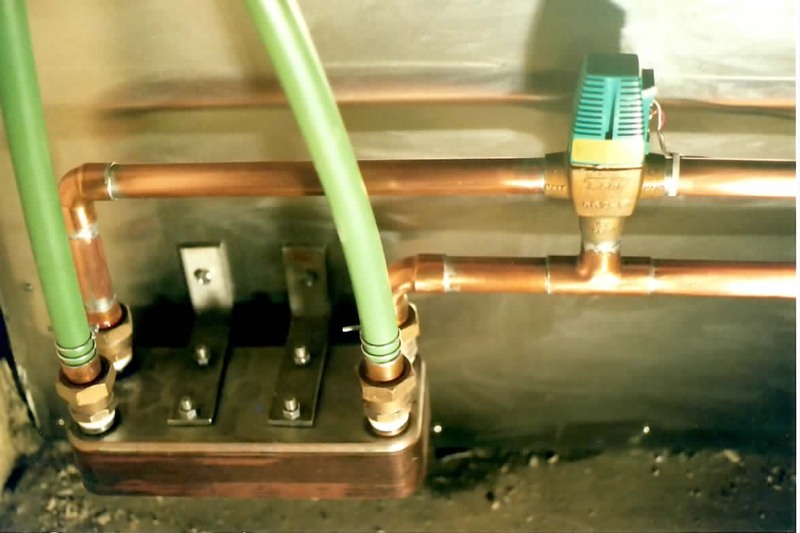

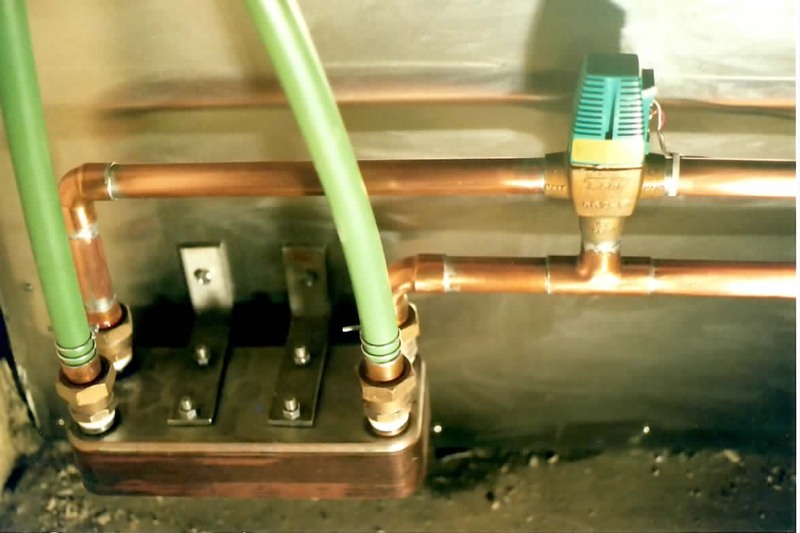

Hot supply is coming in the lower copper pipe. When not called for it U's through the 3 way zone valve and isn't allowed to go through the plate heat exchanger. When heat is needed in the house it goes through the plate when the valve opens. I run the boiler pump 24/7 and use the existing oil furnaces circulator pump(which also runs 24/7) and baseboard heat to distribute the heat throughout the house. Waters never touches each other in the systems if you will. Green poly pipes are to/from the house.

Last night before bed I decide to just turn off the circulator pump on the oil furnace to let the house cool down. I woke up this morning to find the house just as hot.

Am I correct to assume that my Heat exchanger has died and is allowing the water to cross over now and the boilers pump is pumping it through the house. It's the only thing I can see as the pipes are warm 1 story up after 24 hours! I check my water every year as well and it's still in range. I've only had to add condiitioner once to bring it back.

Can't turn wrenches now as I had shoulder surgery but want to see if you guys concurr with what I think has happened. Is this common? Thanks for any input.

I went down thinking the 3 way zone valve had stuck open as it was still sending heat out to the house. Used the manual lever and moved fine. Took the head off and plunger moves up and down freely. I always put a few drips of oil on it at the start of the season. Put it all back and still the same.

At this point I'll explain my system to give a better idea of what I have.

Hot supply is coming in the lower copper pipe. When not called for it U's through the 3 way zone valve and isn't allowed to go through the plate heat exchanger. When heat is needed in the house it goes through the plate when the valve opens. I run the boiler pump 24/7 and use the existing oil furnaces circulator pump(which also runs 24/7) and baseboard heat to distribute the heat throughout the house. Waters never touches each other in the systems if you will. Green poly pipes are to/from the house.

Last night before bed I decide to just turn off the circulator pump on the oil furnace to let the house cool down. I woke up this morning to find the house just as hot.

Am I correct to assume that my Heat exchanger has died and is allowing the water to cross over now and the boilers pump is pumping it through the house. It's the only thing I can see as the pipes are warm 1 story up after 24 hours! I check my water every year as well and it's still in range. I've only had to add condiitioner once to bring it back.

Can't turn wrenches now as I had shoulder surgery but want to see if you guys concurr with what I think has happened. Is this common? Thanks for any input.