chainmailer

ArboristSite Lurker

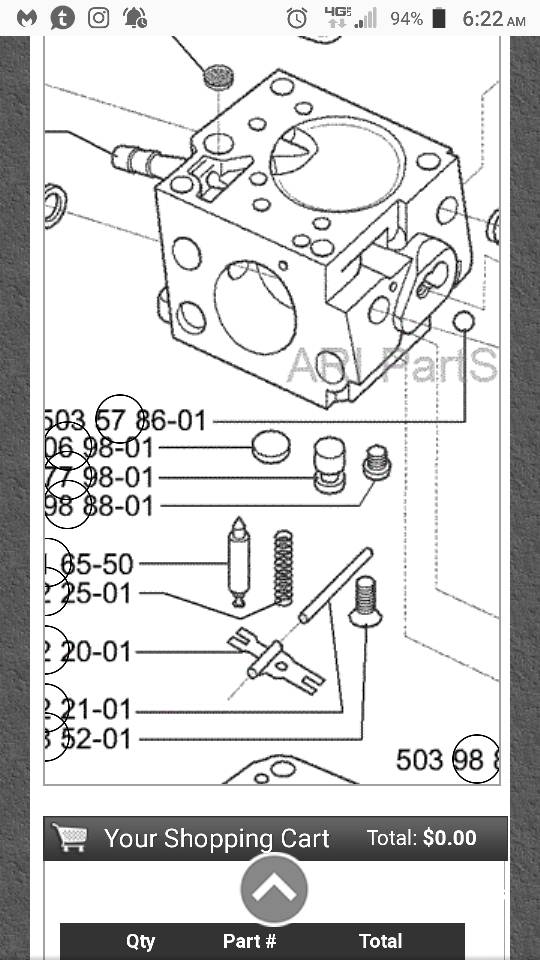

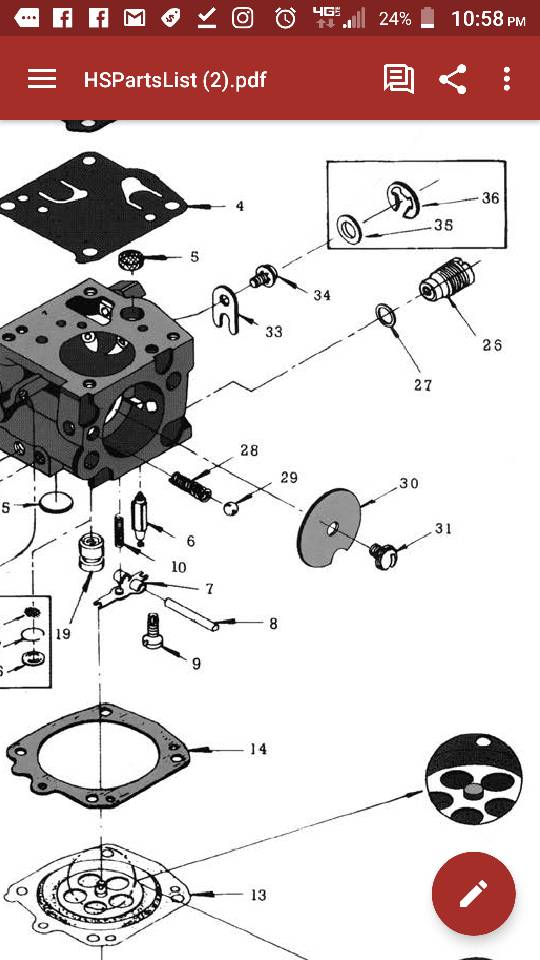

Hi Everyone, new to site so ill introduce myself! My name is Craig Thompson and im into just about everything outdoors! Hunting, fishing, camping ect. Another hobby i have is to find things that are broken for cheap and bringing them back to life! Which is what brings me here today! My latest find is a craftsman 5.2 30" bar that found at yard sale! it is was not running, so after a quick check for compression i offered the guy $20 and guy said no and i started to walk away and he said $20 is too much give ne $10 and its yours! so the rest as they say is history! so long story short is upon further inspection it just seemed like a carb issue so picked up a kit and rebuilt it! I have a buddy who works in a local saw shop and he normally tells me needle settings and fuel needle measurments so he makes things pretty easy for me! but at the moment he is fishing off baja california so i was on my own anyway i decided to try it with out the specs and heres what happened! Saw fired right up but instantly started to rev pretty high but not like wide open but pretty high! i think the pump setting is to high and dumping to much fuel to it! any ideas if not? and if so, do you know where i can get the settings for my carb its a borg warner S176A017 if that helps! thx in advance for any help!