I use Loctite on the bolts, nothing on the gasket (I leave it dry), don't use any primer.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Huztl MS660

- Thread starter Kyler Monares

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

BTarb24

ArboristSite Member

I've built 3 of these 660s so far and done two rebuilds. (one rebuild described below, other was due to a seized crank bearing due to using 50:1 .. switched to 25:1 and have been fine since)

Loctite is a must .. on the first one I built I didn't use loctite on any bolt that already had a dab of blue from the factory. I even torqued the head down with a torque wrench and it still rattled loose after about 20 hours and caused the piston skirt to break and chew itself to pieces. On the other 2 and the subsequent rebuilds I used a liberal amount of red loctite and haven't had a problem.

On my first three builds I used 3bond on both sides of the crank gasket and the piston gasket. They sealed great .. but were a huge pain when i later had to rebuild them. It took about an hour for each case with a razer blade to clean things up. Very delicate work to avoid gouging the soft case material. On my two rebuilds I went with just the bare gaskets. Compression test results for all 5 builds have been consistently around 130psi so i don't think there's any benefit to the gasket sealer.

However, a couple of them leak bar oil while sitting on a shelf. I know on a couple of builds i used 3bond around the oil pickup line's seat in the crankcase and some a couple i didn't .. unsure if there's a correlation to the extra sealer and the leaks or not. Might also be worth mentioning that i forego real bar oil and go with used motor oil instead. The thinner weight may make it easier for it to leak.

Loctite is a must .. on the first one I built I didn't use loctite on any bolt that already had a dab of blue from the factory. I even torqued the head down with a torque wrench and it still rattled loose after about 20 hours and caused the piston skirt to break and chew itself to pieces. On the other 2 and the subsequent rebuilds I used a liberal amount of red loctite and haven't had a problem.

On my first three builds I used 3bond on both sides of the crank gasket and the piston gasket. They sealed great .. but were a huge pain when i later had to rebuild them. It took about an hour for each case with a razer blade to clean things up. Very delicate work to avoid gouging the soft case material. On my two rebuilds I went with just the bare gaskets. Compression test results for all 5 builds have been consistently around 130psi so i don't think there's any benefit to the gasket sealer.

However, a couple of them leak bar oil while sitting on a shelf. I know on a couple of builds i used 3bond around the oil pickup line's seat in the crankcase and some a couple i didn't .. unsure if there's a correlation to the extra sealer and the leaks or not. Might also be worth mentioning that i forego real bar oil and go with used motor oil instead. The thinner weight may make it easier for it to leak.

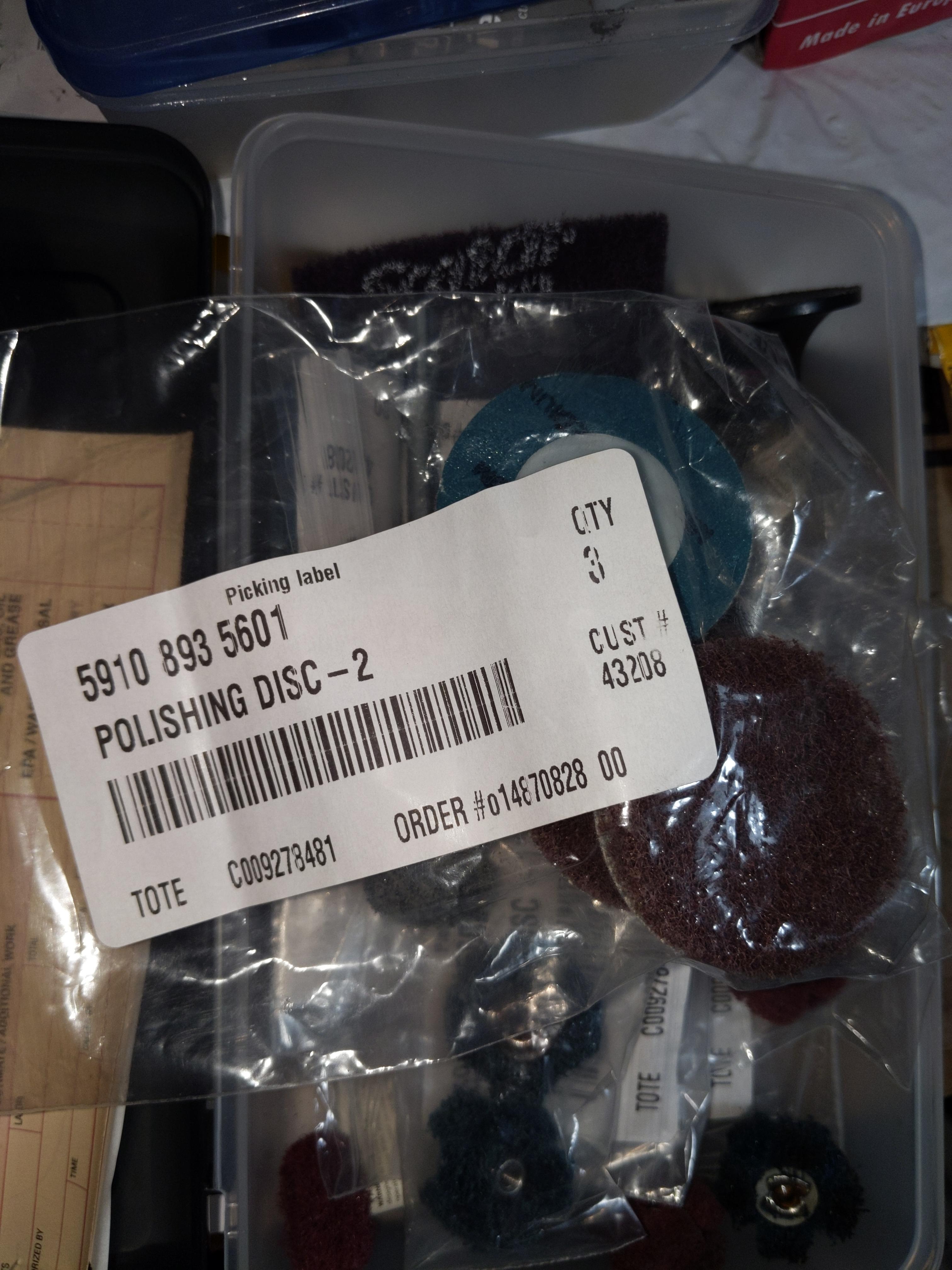

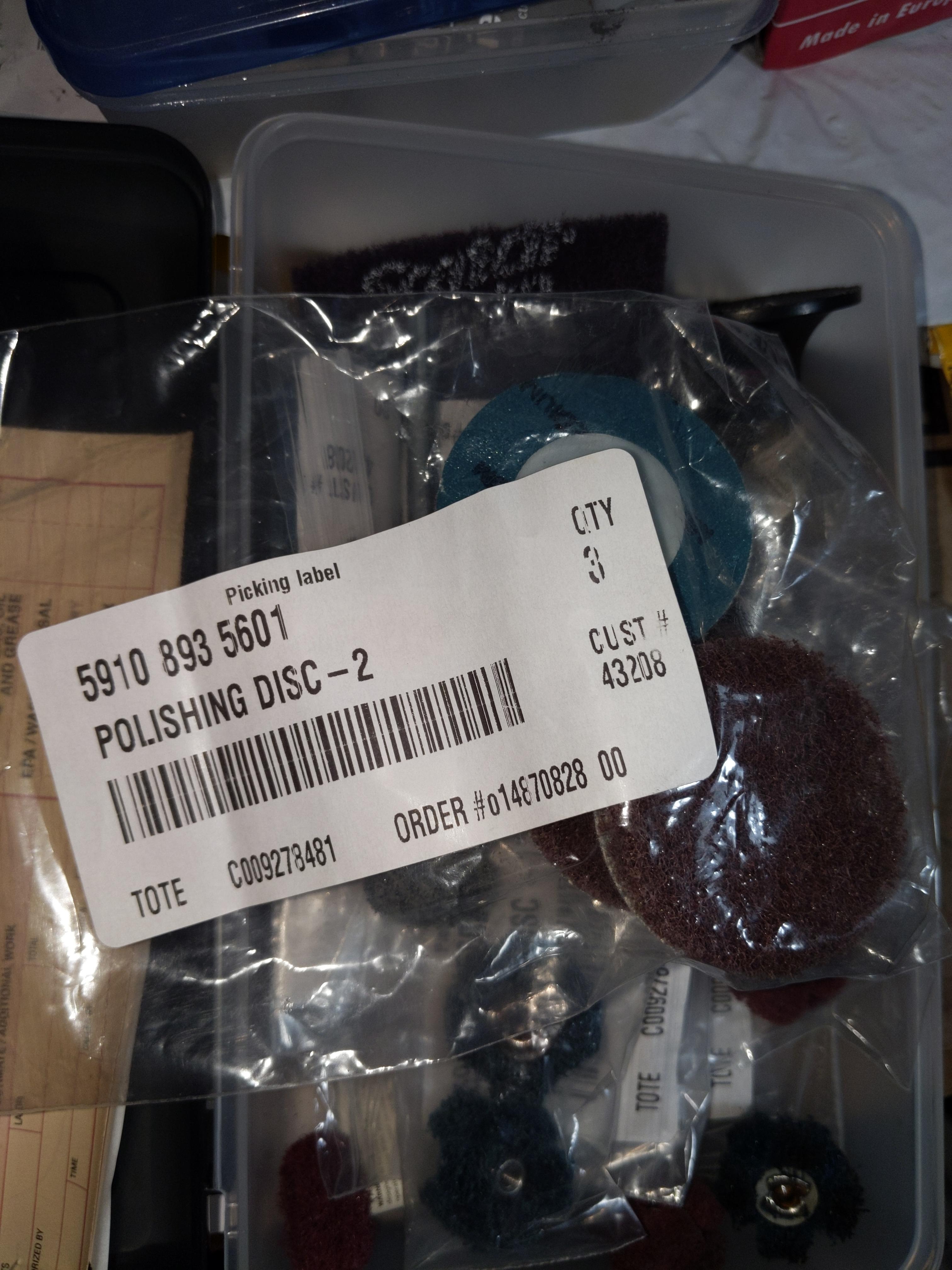

These are available on eBay for use with your Dremel. Hylomar Blue (dirko for cylinder)has been used by Stihl and Rolls-Royce and other companies for years to enhance the gasket. I've never had a case gasket leak. (And to remove one it just requires a little patience and one or two of those little wheels and it comes right off and it does not remove any of the magnesium. The large one is great for bottom of cylinder or a green pad. Cylinder w/ .5mm gasket torque is 15nm. I have learned it's best to apply 243 to the head screws after you have heat conditioned your engine. The cylinder bolts frequently loosen during that initial break in period.

http://thechainsawkitguy.com

https://youtube.com/the1chainsawguy

http://thechainsawkitguy.com

https://youtube.com/the1chainsawguy

Olblacky

ArboristSite Lurker

Thanks guys I'm new here and new to building a saw. Been wrenching on my farm stuff for years. First time building a kit tho. I'm to page 130 taking notes once the rest of my parts are here hopefully this will be a smooth build.

You might want to pick carefully through what you read. Farmertec fixed some of the stuffThanks guys I'm new here and new to building a saw. Been wrenching on my farm stuff for years. First time building a kit tho. I'm to page 130 taking notes once the rest of my parts are here hopefully this will be a smooth build.

http://thechainsawkitguy.com

https://youtube.com/the1chainsawguy

BTarb24

ArboristSite Member

I got one of the first kits on the forum and my latest was a blue one last year. So far I've been fine without having to buy any oem replacement components. The only hutzl part that frustrated me was the carb.. they can be a pain to tune but they all eventually feel into line.

I don't use used oil any more … not worth replacing bars prematurely and bar oil is cheap (TS for $6/gal).

There is an oil pressure valve that can leak under the bar protector. Can reset it with a pick. If they saws get hot (in the truck) oil will leak. Even my brand new OEM Stihl saws leak oil if they are full and get hot.

There is an oil pressure valve that can leak under the bar protector. Can reset it with a pick. If they saws get hot (in the truck) oil will leak. Even my brand new OEM Stihl saws leak oil if they are full and get hot.

bigG

ArboristSite Member

I bought one on Amazon a while back for $260 that was assembled with bar, chain and handle. Just had to attach handle, bar and chain. That sucker flies every bit as good as my neighbors Stihl 066.Well, $98.89...so call it $100. Total for the kit and shipping is $240.88

Olblacky

ArboristSite Lurker

Olblacky

ArboristSite Lurker

I'm not great at sharing things. But I took a couple pics of the tools I made to pull the crank in. The PTO side worked but I shoulda put a lil more care into it that hole in the all thread is bad crooked and it's essentially Matt's design. The flywheel side I did a little different and a welded it but I don't think I woulda had too. I used a steel 1/4" npt pipe coupling and screwed a piece of 1/2" allthread into in 2.5 turns before it bound up. Then on the other end I screwed in a 1/8 x 1/4 npt brass bushing. Per the recommendation here that m10*1.0 is close to 1/8npt I got 4 turns on before it bound up. And its brass so it didn't hurt my crank.

Looks like it might be part #29 on this IPL page:Almost got my saw together today. Did it at the house instead of the shop so I didn't have a 13mm deep socket to tighten the decompression.

Don't eat meI haven't mastered searching for this one so I'll ask. Got a spare part where's it go?

View attachment 847499View attachment 847500

Olblacky

ArboristSite Lurker

I purchased a hlsupply kit on a deal of the day awhile back after reading some of this forum. Then I did more reading. Lol Then I ordered some OEM parts. OEM parts I bought and would I do it again.

1122-007-1053 gasket kit $39 yes

9512-003-3281 wrist pin bearing $22 YES

1122 034 1500 Piston pin Piston wrist pin $10 backordered put it together with hlsupply pin

9463 650 1200 Snap ring 12x1 Wrist clips .29 Yes I ordered 4 and didn't loose any lol

1122-141-2201 intake manifold rubber $48 probably not

1128 020 9400 Decompression valve $15 yes

1127 141 8600 Impulse hose $12 maybe

1120 036 8500 1 Woodruff key 2x3.7 $2 maybe. I ordered 3 in case I shear one or wanna attempt to adjust timing

0000 963 0808 3gromet brass for cylinder cover $2 no didn't need

1122-007-1053 gasket kit $39 yes

9512-003-3281 wrist pin bearing $22 YES

1122 034 1500 Piston pin Piston wrist pin $10 backordered put it together with hlsupply pin

9463 650 1200 Snap ring 12x1 Wrist clips .29 Yes I ordered 4 and didn't loose any lol

1122-141-2201 intake manifold rubber $48 probably not

1128 020 9400 Decompression valve $15 yes

1127 141 8600 Impulse hose $12 maybe

1120 036 8500 1 Woodruff key 2x3.7 $2 maybe. I ordered 3 in case I shear one or wanna attempt to adjust timing

0000 963 0808 3gromet brass for cylinder cover $2 no didn't need

BTarb24

ArboristSite Member

I've forgotten to install that piece on one of mine and I can't tell the difference. I wouldn't bother taking it apart to install it.

Olblacky

ArboristSite Lurker

Good catch atpchas not sure how I missed that. Wonder how much I'm going to hate myself trying to get that in there now. Two steps forward 2.1 back

Olblacky

ArboristSite Lurker

I may wait to take it apart to put that piece on until I find out I messed up something else lol

Olblacky

ArboristSite Lurker

As others have said it started on the 4th pull. Let it idle and fast idle a minute. Now we wait for a bar to get here. I may have to let it idle a few more times until then just to listen to it run! Man this thing sounds mean and I haven't even done any mods to it!! Yet hehe

jaggedscars

New Member

Good evening!

Previously build two of these kits and at that time (2016-2017) there was chain brake issues. Just purchased another kit this last week. Have they resolved the chain brake issue or should I still order an OEM handle and/or linkage?

Thanks,

Jagg

Previously build two of these kits and at that time (2016-2017) there was chain brake issues. Just purchased another kit this last week. Have they resolved the chain brake issue or should I still order an OEM handle and/or linkage?

Thanks,

Jagg

arto_wa

ArboristSite Operative

.........zip.........Previously build two of these kits and at that time (2016-2017) there was chain brake issues. Just purchased another kit this last week. Have they resolved the chain brake issue or should I still order an OEM handle and/or linkage?

Thanks,

Jagg

My MS660 kit was delivered in December 2019 and I replaced the brake lever couple of months ago with OEM part 1128 160 5000 which corrected the issue of brake handle coming too close to the exhaust muffler.

jaggedscars

New Member

Thanks for confirming! Excited to build one of these kits for me this time versus selling.My MS660 kit was delivered in December 2019 and I replaced the brake lever couple of months ago with OEM part 1128 160 5000 which corrected the issue of brake handle coming too close to the exhaust muffler.

View attachment 857001

There are two brake handles. One slopes making room for wrap handle and it's just off the muffler. The kits contained the one for the wrap handle from day one. Now no telling. The lever you speak of does not, did not have anything to do with the position of the brake handle relating to muffler. I think they put the wrong lever in the kit and that is why that lever got replaced. The threads are so long people get confused.My MS660 kit was delivered in December 2019 and I replaced the brake lever couple of months ago with OEM part 1128 160 5000 which corrected the issue of brake handle coming too close to the exhaust muffler.

View attachment 857001

http://thechainsawkitguy.com

https://youtube.com/the1chainsawguy

Similar threads

- Replies

- 27

- Views

- 2K

- Replies

- 12

- Views

- 724