....Part of a Radius anyway.

I looked at a Job yesterday that has a small wooden foot bridge.

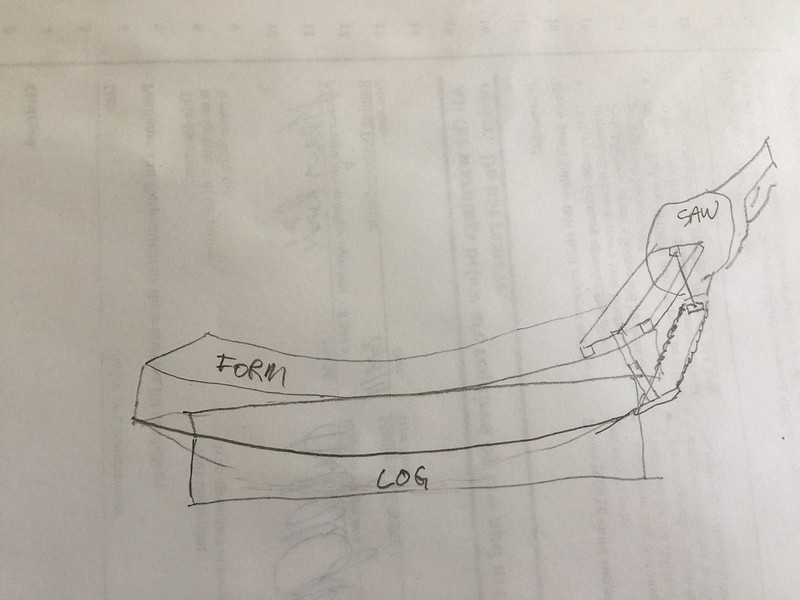

It got me thinking... I have a Cedar Log that I could cut the curved Bridge deck out of one piece.

Has anyone created a curved jig to run their chainsaw mill against?

Can a Chainsaw go any direction other than dead flat straight?

The radius on this is bridge top is relatively slight. I would cut the jigs out of plywood on the bandsaw.

Iirc the bottom is drawn to be flat but I could make a separate jig to cut it in a parallel curve to the top.

It seems like I should be able to get the chainsaw mill to follow the curve but,.... maybe I'm asking for huge trouble.

I have done tons of laminating curves for stairs and other architectural details and structures.

Chainsaw is pretty new to me but it seems to follow the rules of most other wood working tools.

The bridge deck is 24" wide so bandsawing is not going to work.

Anyone get near something like this before?

I looked at a Job yesterday that has a small wooden foot bridge.

It got me thinking... I have a Cedar Log that I could cut the curved Bridge deck out of one piece.

Has anyone created a curved jig to run their chainsaw mill against?

Can a Chainsaw go any direction other than dead flat straight?

The radius on this is bridge top is relatively slight. I would cut the jigs out of plywood on the bandsaw.

Iirc the bottom is drawn to be flat but I could make a separate jig to cut it in a parallel curve to the top.

It seems like I should be able to get the chainsaw mill to follow the curve but,.... maybe I'm asking for huge trouble.

I have done tons of laminating curves for stairs and other architectural details and structures.

Chainsaw is pretty new to me but it seems to follow the rules of most other wood working tools.

The bridge deck is 24" wide so bandsawing is not going to work.

Anyone get near something like this before?