big daddio

ArboristSite Operative

anybody out there made their own swing saw? recovering from back surgery and getting tired of picking up slabs to convert to firewood. i know how creative home millers are. help.

So, what are you going to do with that big heavy slab that a swing mill leaves behind? (at ground level no less)

Every mill has slabs....unless you leave the bark on the lumber.

My back has issues too, so i saw the 4 slabs that come off the log into 4' lengths "before" i remove them off the mill... They are much lighter, and they stack into a nice 4'x4'x4' stack that i can use later, or sell as 1/2 cord...

Rob

I could be wrong but he is talking about a swing blade mill (see Lucas or Petersen mills) and they don't leave slabs but rather they leave dimensional lumber so all you are handling is a 2x8 or at most an 8x8, with the ability to cut a 8X16 if you need to.

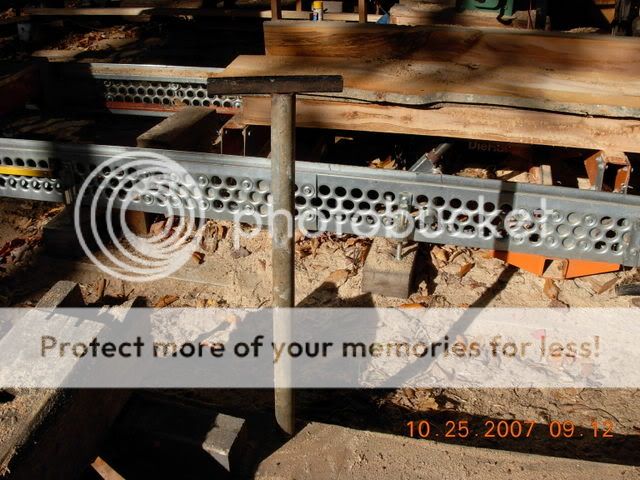

I too would be interested in if anyone has built one.. I would love one but couldn't justify it so I would like to make one if it weren't too far over my head

i'll try that cutting the slabs as soon as they come off Rob. hopefully the back issue will be better by the end of this month [got to go back to the real job] i mostly cut small logs [10 to 20'' and free] and do a lot of edging to get the most out of them. that cut off saw of yours, does it have a stationary blade or does it swing or slide through the wood? thanks oh yeah, went and bought me one of those little husky saws at the hardware store, lot better than the 064 stihl for slab chopping

Swing mills aren't magic... ALL sawmills produce slabs!!

Sorry Rob disagree. A Lucas mill can turn a log into 1 x 1" strips without cutting a single slab first. You can even do the same with a CS on a suitable rig.

From what you are saying it sounds like you have never seen one working.So you substitute the word "edgeing" for the word "slab"? Big deal, who wants that?? And what about what's left on the ground when your done sawing??? I guess you can call that a "carcus" instead of a "slab"... No matter, someone has to lift it and deal with it, no matter what you call it...

I don't think any of my customers would be too happy if i sawed all there logs into 1" strips, or left the edges on... For some reason they seem to like bigger dimentions, and every tree i've ever seen needed some bark, or edge sawn off it to get to the "good stuff"...

Rob

From what you are saying it sounds like you have never seen one working.

With a swing mill there is no need ever have to pick up a "slab" or a large face cut like you do with a BS or CS mill and all the edges are cut of as strips as you go. If you can't work it out I can show you a diagram of a cutting sequence that shows this. I'd much rather be picking pieces of 4 x 2 and 8 x 1 by hand of a log, than handling slabs 12 - 18" x 2 or wider. Same with the edge strips (there are no large face cuts. You can even cut the "remaining carcass" into 2" wide strips when your are done. And as an added bonus is one does not need to turn cants.

From what you are saying it sounds like you have never seen one working.

With a swing mill there is no need ever have to pick up a "slab" or a large face cut like you do with a BS or CS mill and all the edges are cut of as strips as you go. If you can't work it out I can show you a diagram of a cutting sequence that shows this. I'd much rather be picking pieces of 4 x 2 and 8 x 1 by hand of a log, than handling slabs 12 - 18" x 2 or wider. Same with the edge strips (there are no large face cuts. You can even cut the "remaining carcass" into 2" wide strips when your are done. And as an added bonus is one does not need to turn cants.

I'm with BobL here.

The thing with a swingblade is you can take of those outside slabs in small dimensioned pieces. It is usually quicker to slice them up into 6x2 type sizes, or whatever you use for firewood in those parts, on the mill and they are much easier to handle. If you are taking off edgings too skinny for firewood, thats because you have recovered more boards from the log, that has to be a good thing. You are left with a full width slab on the bottom of the log, but just slice that up with the chainsaw if it's too big to move easily.

Also you can Q-saw without having to move large quarters of a log.

Now I agree that no one mill suits every task, and swingblades are at their best taking dimension lumber off BIG logs. But they can handle smaller hardwood logs perfectly well, just like any other saw can.

Personally I think that the lack of log handling puts them above a manual band saw when cutting ANY log, but they are a little more expensive of course. I do admit I am biased too

But for someone with a bad back the lighter slabs and easy log

handling might be more important than any other factor like board width and kerf etc.

Cheers

Ian

Thanks Ian - I was hoping you'd chip in - you put the words together better than I could. I agree that on BIG logs they really shine - the bigger the log the greater proportion of timber they can recover.

Rob - I think I see the confusion. Slab to me means either a large (as in wide) face cut, or a piece spanning the whole width of a tree - the sorts of things Aggie cuts. That's what I'm talking about lifting, not the edging.

I think its fair to say ALL mills make slabs

Enter your email address to join: