treecharger

ArboristSite Lurker

Hi tree folks,

I'm a solar electric system dealer in Washington State, where a lot of off-grid folks live deep in the woods. Solar PV panels do not work in the shade.

Most of my tree climbing is to put solar panels up in the tops of trees so they can be in the sunshine.

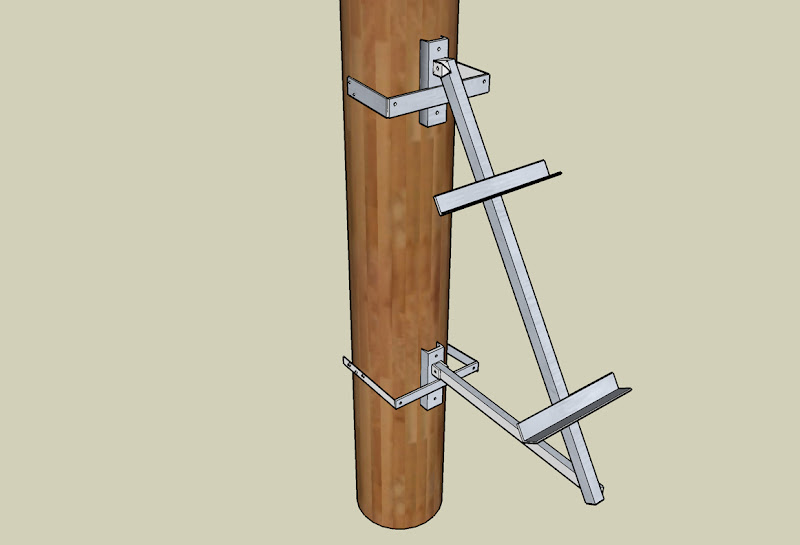

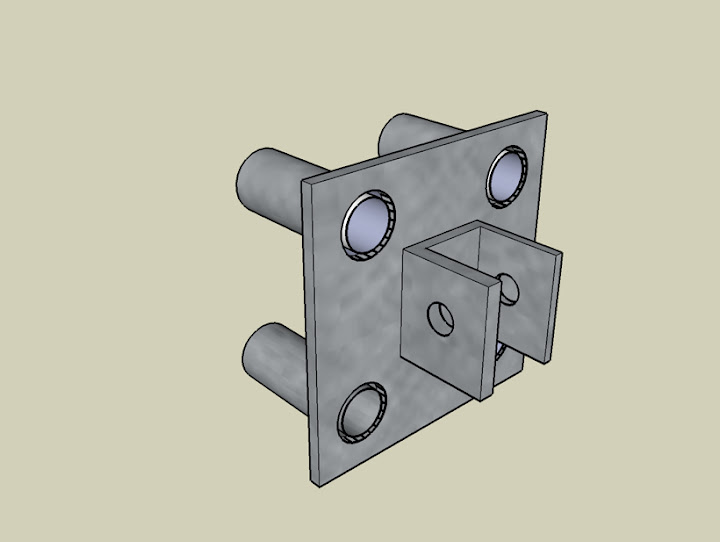

My question is, what would you recommend as the best way to attach the rack to the tree? The "side of pole" mount racks that we get have a steel band that wraps around the 'pole' (tree) to squeeze the rack to it. That creates a partial girdle of the tree, however, so I'm looking for a better alternative.

I can bolt the rack straight to the tree, but it is nice to have the sway bracing of the strap. I'm thinking of a combination of face bolting with some side braces bolted also to help with the twisting motion.

What kind of fasteners are okay for trees?

Galvanized lag bolts?

Stainless lag bolts?

Threaded rod thru bolted? galvy or stainless?

something else?

I usually remove enough limbs in the area of the panel(s) to reduce the sail area by about as much as I'm adding with the panels, and to prevent shading from lower limbs that will grow up in front of the panels eventually.

Solar panels in treetops is a great way to get clean quiet power to an off-grid location in the woods, but I want to be sure that I'm doing the best I can for the trees. Thanks in advance for your suggestions.

Eric

islandenergysystems.com

solarempowerment.ning.com

I'm a solar electric system dealer in Washington State, where a lot of off-grid folks live deep in the woods. Solar PV panels do not work in the shade.

Most of my tree climbing is to put solar panels up in the tops of trees so they can be in the sunshine.

My question is, what would you recommend as the best way to attach the rack to the tree? The "side of pole" mount racks that we get have a steel band that wraps around the 'pole' (tree) to squeeze the rack to it. That creates a partial girdle of the tree, however, so I'm looking for a better alternative.

I can bolt the rack straight to the tree, but it is nice to have the sway bracing of the strap. I'm thinking of a combination of face bolting with some side braces bolted also to help with the twisting motion.

What kind of fasteners are okay for trees?

Galvanized lag bolts?

Stainless lag bolts?

Threaded rod thru bolted? galvy or stainless?

something else?

I usually remove enough limbs in the area of the panel(s) to reduce the sail area by about as much as I'm adding with the panels, and to prevent shading from lower limbs that will grow up in front of the panels eventually.

Solar panels in treetops is a great way to get clean quiet power to an off-grid location in the woods, but I want to be sure that I'm doing the best I can for the trees. Thanks in advance for your suggestions.

Eric

islandenergysystems.com

solarempowerment.ning.com

You should really read up on proper tree pruning, i see some nasty cuts in those pics.

You should really read up on proper tree pruning, i see some nasty cuts in those pics.