Kevin

@huskihl did an amazing job on this saw. He can correct me if Im wrong but I think this 3120 was the first one he did. Sorry if i botched that comment Kevin.

Starts easy, but needs the de-comp!! I hurt my arm really good a few times trying it without the de-comp on accident. Forearm muscles were very bad for 3 weeks.

Now that I learned that lesson and check that the de-comp is on every time it will start super easy. And it is a monster as expected. Full of torque.

Intake is stock

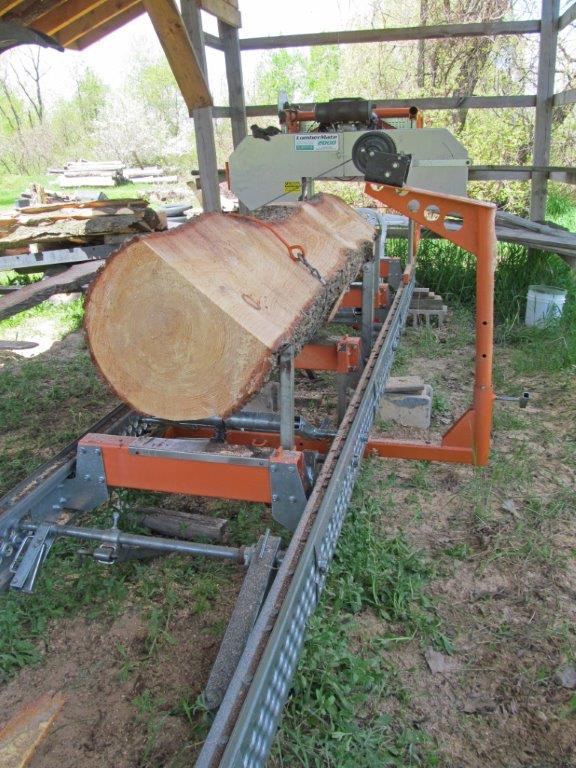

Red Oak. First thing that saw milled. 32” diameter

View attachment 1165397

He he he.

I had a few backfires on the 084

Starter handles, rope rotors then my hand. Six weeks starting left handed. Took as long as when I broke my right wrist years ago. That was interesting setting the end.

My 660 has no decomp now. It swallowed one last year. Opps installed an AM one and it melted

Need to buy a 3120 and drill it six ways! This thing sucks cold start.

I doubt Kevin was practicing on your saw though. He knew damn right well what what rabbit hole he chose to go down before ever buying any tools I'm sure. At least he had no presumptions or bad habits to work around. Almost every mechanic I've ever met or engine builder is bias by what to do based on so and so said or that's how my grandpa "name here" did it

is my normal response. He got none of the, this is how you should do it, bs, because most of us have our own shop for small engine work. I was cursed with that stuff growing up around others and car guys or toys or dirt bikes. Because Bob said, the book says, my uncle always.... and so on and so forth. Elimination of most of that noise definitely helps sort what works and what doesn't. Test test tests and test again. That point seems to be moot in most people's mind now. They think a computer doing simple math somehow negates that need to test. It was our only way to know how something reacts in the real

1970s or 80s where we acually lived. That will never change among the best builders.

Dynos are nice for tuning if you have a setup but not much good in the real world, facts. Asked anyone who builds "usable" stuff not trailer queens. Getting to see changes on them is priceless if you follow the rule one change at time not three or two. Good tool but not the test bed most have going on in the real world.

Just fishing altering the fuel circuit on a 2186. Impulse system was strengthen and the pump arm was adjusted. Hopefully the spring can stay stock. It's looking at real 36" bar in 3/8 063. Doubt these were ever right from the factory on the fuel circuit. Kelvin would definitely have better info on that.

This is my first one and sadly the likelihood is the last one to ever come here. The elbow inlet is a joke based on the shape inside. They are mostly gone from daily use now and this saw is clean. Just came off a decade hyatis. Slated to eat hardwoods for splitting. Piston was nice but the rings were goo'dup and stuck somewhat. Rings were torched. Came in a box apart. Considered tring a 42" bar on it. The oil pump seems capable.

You ever run these saws?