stonykill

ArboristSite Guru

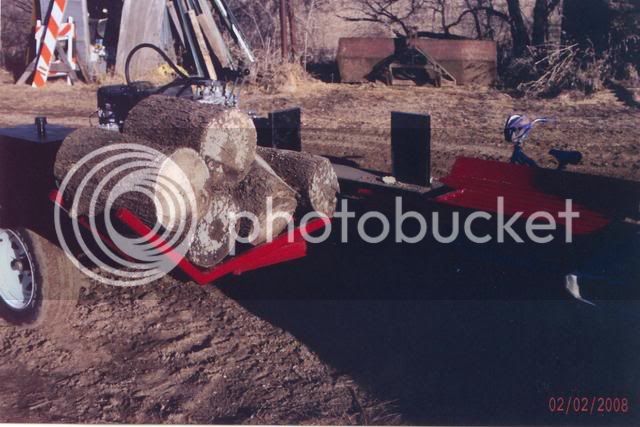

I have to admit I like the lift as well, it works about the way I figured it would. I used a 3x16 cyl I had around here so I didn't have to buy another one and it really it is to long and to big. It will be fine for now I may look to get a 2x14 or something like that. I didn't quite get the geometry like I should've and it hits a bar on the top if it is lifted almost straight up. My son got a little wild and over did it the other nightand I had to do a little surgery to correct it but that's ok for 9 he is good help otherwise... I have been thinking about a 4 way wedge but really it isn't all that bad with the table on front to re-split when necessary. Guess after about 30 yrs of not having a splitter I am just glad to have my own and don't know anybetter...

I don't have a 4 way either. Just always thought of adding one. The table does make a big difference. I need to build a new table for my splitter, had to remove what was left of the old one. I've thought of a log lifter. I'm only 40 but my back is 60 some days. Maybe someday.