LeakyWoodDoctor

ArboristSite Lurker

My Home-made DHW Heat Syphon!

Hey,

I was looking for a place on this forum to put up general OWB plumbing information and this looks like the spot!

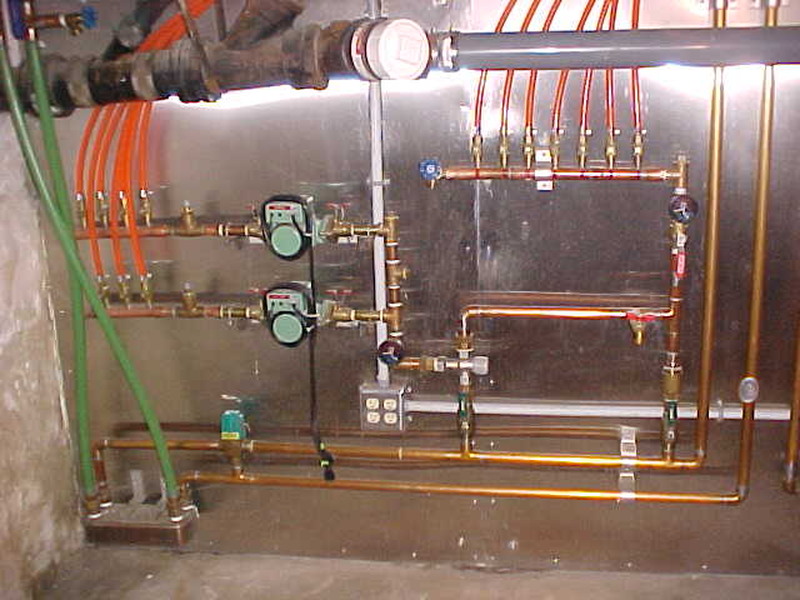

My siphon is made from 1.5" black iron and 3/4" copper with a mixing valve at the top acting as a shut off to prevent cold water from rushing through the siphon and mixing with hot water leaving the top of my DHW tank.

I have also piped the bottom with some ball valves which allow easy addition of water into my OWB to top it up every now and then! It's not much fun dragging a hose all the way over to the boiler (see a little further down in my other post) !!

Check it out . . .

http://**************************/forum/index.php?topic=126.0

Hey,

I was looking for a place on this forum to put up general OWB plumbing information and this looks like the spot!

My siphon is made from 1.5" black iron and 3/4" copper with a mixing valve at the top acting as a shut off to prevent cold water from rushing through the siphon and mixing with hot water leaving the top of my DHW tank.

I have also piped the bottom with some ball valves which allow easy addition of water into my OWB to top it up every now and then! It's not much fun dragging a hose all the way over to the boiler (see a little further down in my other post) !!

Check it out . . .

http://**************************/forum/index.php?topic=126.0

Last edited: