Paraord

ArboristSite Lurker

Hi Everyone,

Newbie here on ArboristSite from Western NY. Decided to take the dive into a wood burning stove as I had to take down a 3' diameter pignut hickory tree a few weeks ago in order to get ahead of the long horned hickory borer beetles (and avoid any damage of it coming down unscheduled). Not ever being one to let anything go to waste this was the catalyst for using wood heat on our small farm.

I have had this Stihl 028 Super for must be 6 or 7 years, got it long ago for a song and a dance and never really fiddled with it until now. Got it running mint and it really just screams through that hickory. Serial number is 22045655 (to help the experts with any applicable information, side note if anyone knows the age let me know otherwise Ill give Stihl a shout on Monday)

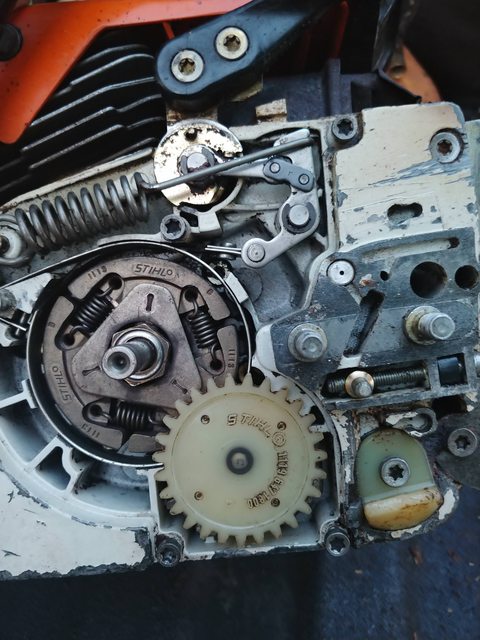

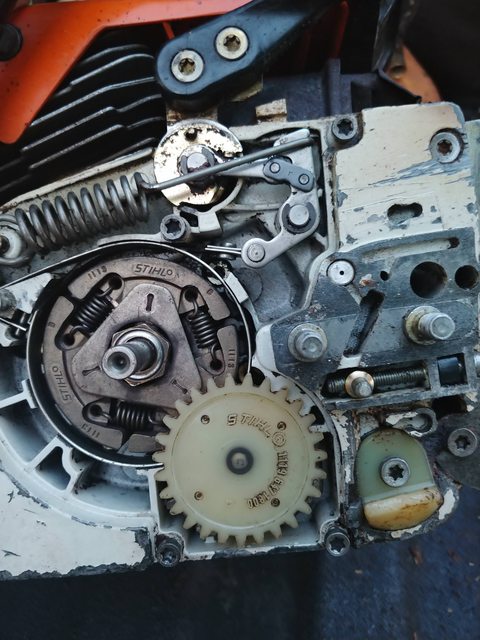

The bar was a little worn towards the ends due to what I assume was from an overtightened chain and looking at the sprocket it could use a change. So i figured I would do the 'ol rim sprocket conversion and a new stihl bar because I am going to be using this much more frequently.

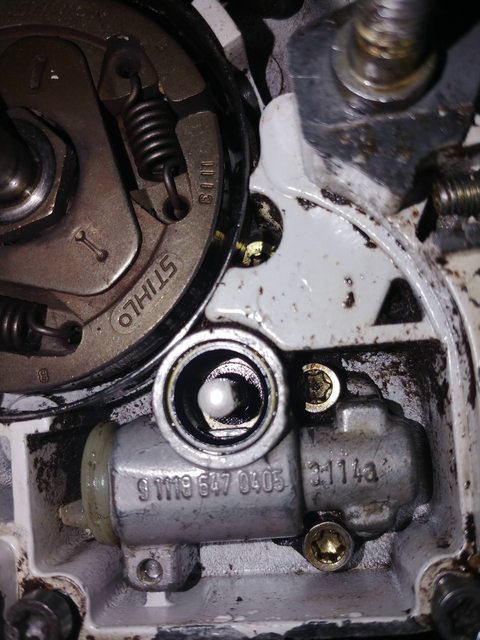

Aside from that whenever I left it for a few days the bar oil would leak out pretty good from what I assume (and talking with a local stihl repair shop) is likely the oil pump seal. So I got one of those too because ya know, while I'm in there right?

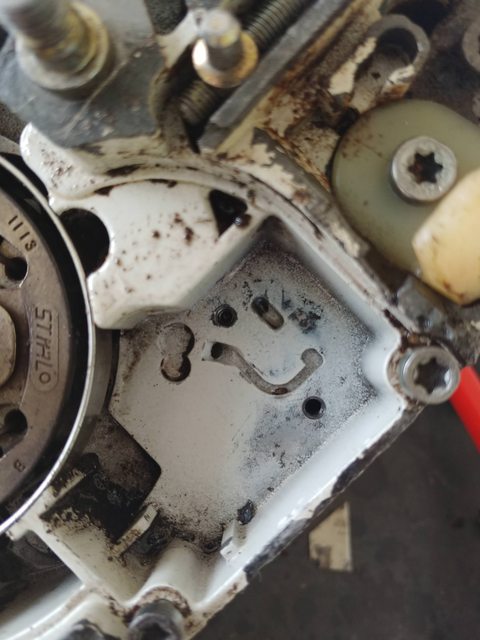

When I started doing some research I noticed I didnt have a bar back plate, but I am not seeing any threaded holes for screws to hold one on. So thats question #1.

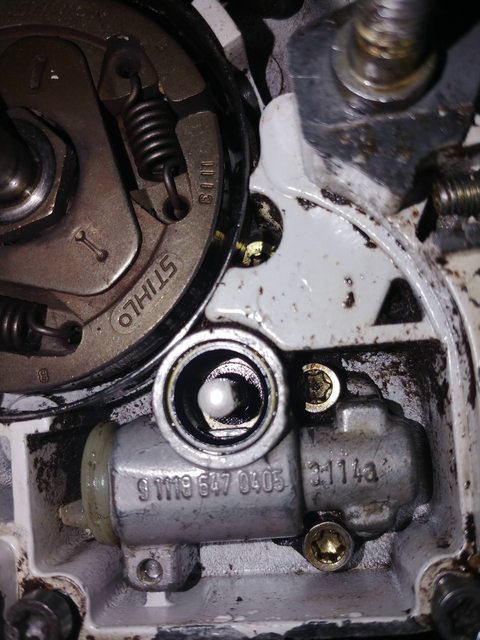

So anyways I kept on trucking with the take down. Needle bearing is shot so in the morning Ill have a cup of coffee and hit a few places for one local. On to the next thing. I get the gear off the oil pump and take out the 2 screws but the oil pump is not budging. Queue question #2. Is there a trick to this or am I missing something like a hidden screw? Im no stranger to engines but the parts on my 1953 Farmall Super M are a bit more robust and thats what I am used to, these small parts make me a little nervous that I am going to give them the Lenny treatment from 'Of Mice and Men'.

Of course this thread needs some pictures so here we are

Well I suppose thats enough rambling for now. Thanks in advance everyone!

-Andrew

Newbie here on ArboristSite from Western NY. Decided to take the dive into a wood burning stove as I had to take down a 3' diameter pignut hickory tree a few weeks ago in order to get ahead of the long horned hickory borer beetles (and avoid any damage of it coming down unscheduled). Not ever being one to let anything go to waste this was the catalyst for using wood heat on our small farm.

I have had this Stihl 028 Super for must be 6 or 7 years, got it long ago for a song and a dance and never really fiddled with it until now. Got it running mint and it really just screams through that hickory. Serial number is 22045655 (to help the experts with any applicable information, side note if anyone knows the age let me know otherwise Ill give Stihl a shout on Monday)

The bar was a little worn towards the ends due to what I assume was from an overtightened chain and looking at the sprocket it could use a change. So i figured I would do the 'ol rim sprocket conversion and a new stihl bar because I am going to be using this much more frequently.

Aside from that whenever I left it for a few days the bar oil would leak out pretty good from what I assume (and talking with a local stihl repair shop) is likely the oil pump seal. So I got one of those too because ya know, while I'm in there right?

When I started doing some research I noticed I didnt have a bar back plate, but I am not seeing any threaded holes for screws to hold one on. So thats question #1.

So anyways I kept on trucking with the take down. Needle bearing is shot so in the morning Ill have a cup of coffee and hit a few places for one local. On to the next thing. I get the gear off the oil pump and take out the 2 screws but the oil pump is not budging. Queue question #2. Is there a trick to this or am I missing something like a hidden screw? Im no stranger to engines but the parts on my 1953 Farmall Super M are a bit more robust and thats what I am used to, these small parts make me a little nervous that I am going to give them the Lenny treatment from 'Of Mice and Men'.

Of course this thread needs some pictures so here we are

Well I suppose thats enough rambling for now. Thanks in advance everyone!

-Andrew