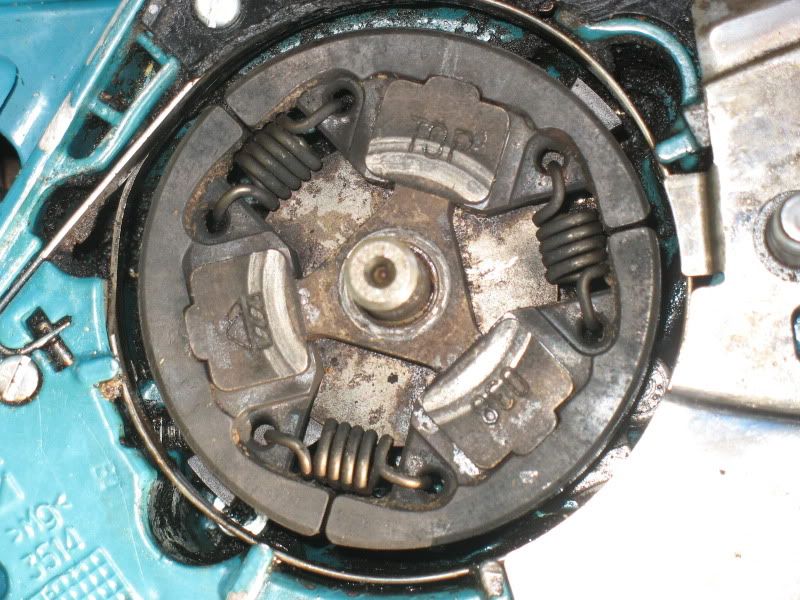

You have a rim sprocket, so the thickness of the washers, no matter where you put them, is not going to make that much difference. The rim floats on the clutch drum. I realize that the IPL shows the washer on the outside of the clutch drum, but I will sometimes put it on the inside IF the drum is rubbing the clutch. To tell if this is the case, put the drum and bearing on the crankshaft and while lightly pressing on the drum, rotate it by hand. If you feel or hear it rubbing the clutch, place the washer under the drum. Then repeat the process and it should not rub. Many times when I set up a new saw, I will move the outer washer to the inside. As far as the E-clip on fitting back on, make sure that the ears on the clutch drum are not lined up with the oil pump drive. They need to slip past the drive tabs in order for the clutch to fit correctly onto the crankshaft.

In regards to replacing the bearing, if the bearing is separate from the drum, just the bearing can be replaced. If the bearing is pressed into the drum, it is often easier to replace the entire clutch drum. Either way, when ever you have the clutch drum off, place a dab of grease on the bearings and shaft to help lubricate them. This bearing is something that is often neglected and should be greased regularly to ensure maximum life, especially if the saw spend a lot of time idling. (idle is the only time this bearing actually gets used)