Jimbo209

ArboristSite Guru

What fluids are being used to clean parts both remedies and commercial products

What works and where on bits such as

Chains

Mechanical ie, carb

Body - cases, clutch covers,mufflers, plastic, mag and steel.

Thinking lemon juice, metho, turps, detergents from dish soap to simple green, bicarb, unleaded gas, diesel??? Some won't mix I know, just what.

Or other similar fixes like Have also found stainless kitchen polish great for bars

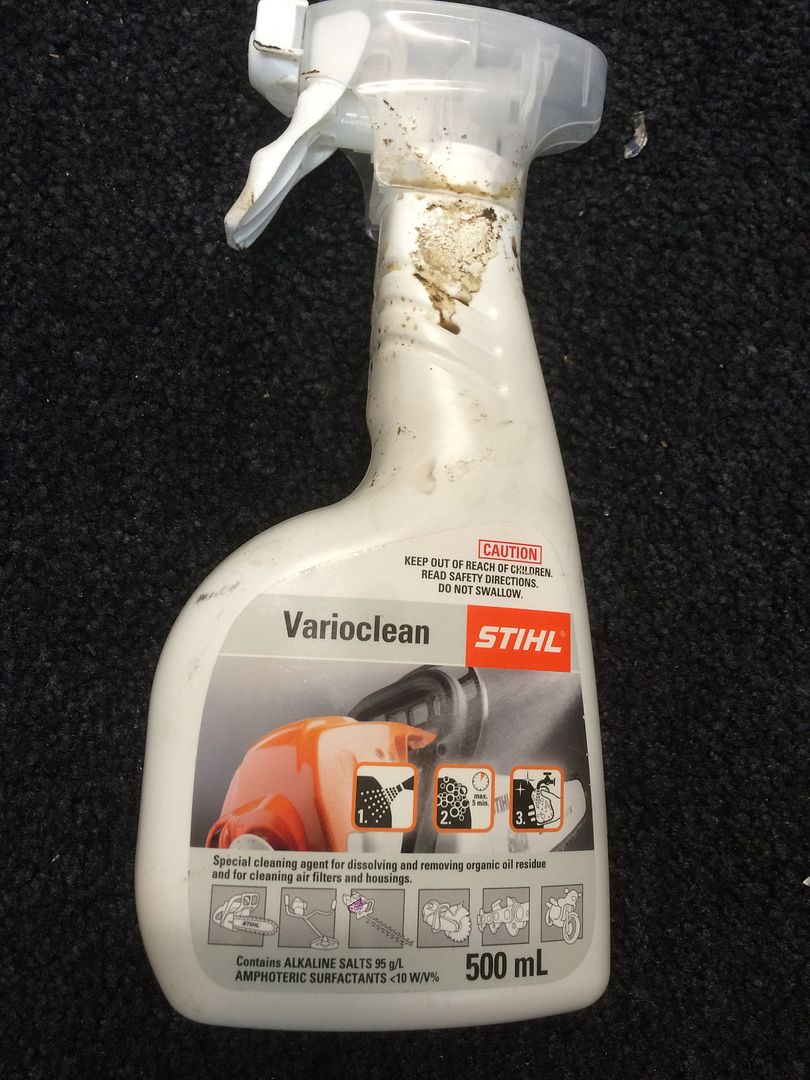

Posting this as I have just got this

What works and where on bits such as

Chains

Mechanical ie, carb

Body - cases, clutch covers,mufflers, plastic, mag and steel.

Thinking lemon juice, metho, turps, detergents from dish soap to simple green, bicarb, unleaded gas, diesel??? Some won't mix I know, just what.

Or other similar fixes like Have also found stainless kitchen polish great for bars

Posting this as I have just got this