I have available a bunch of 27" long boards from a sawmill, all about 2 full inches thick and 2-1/2" to 3" wide. These were cut from left over short stock but it really isn't waste--its all white and red oak, virtually knot free. I'm not sure exactly what to do with them, but burning them in the stove seems like a pity. So, here's what I thought:

What about short sawbucks? If you think about it, the idea of a sawbuck is to get logs off the ground. The higher the sawbuck is, the more work you have to do to lift it the long log on board, and the heavier the log, the worse it gets. Even if the log were only 14" off the ground, it seems like a short sawbuck would do the trick, especially for big logs.

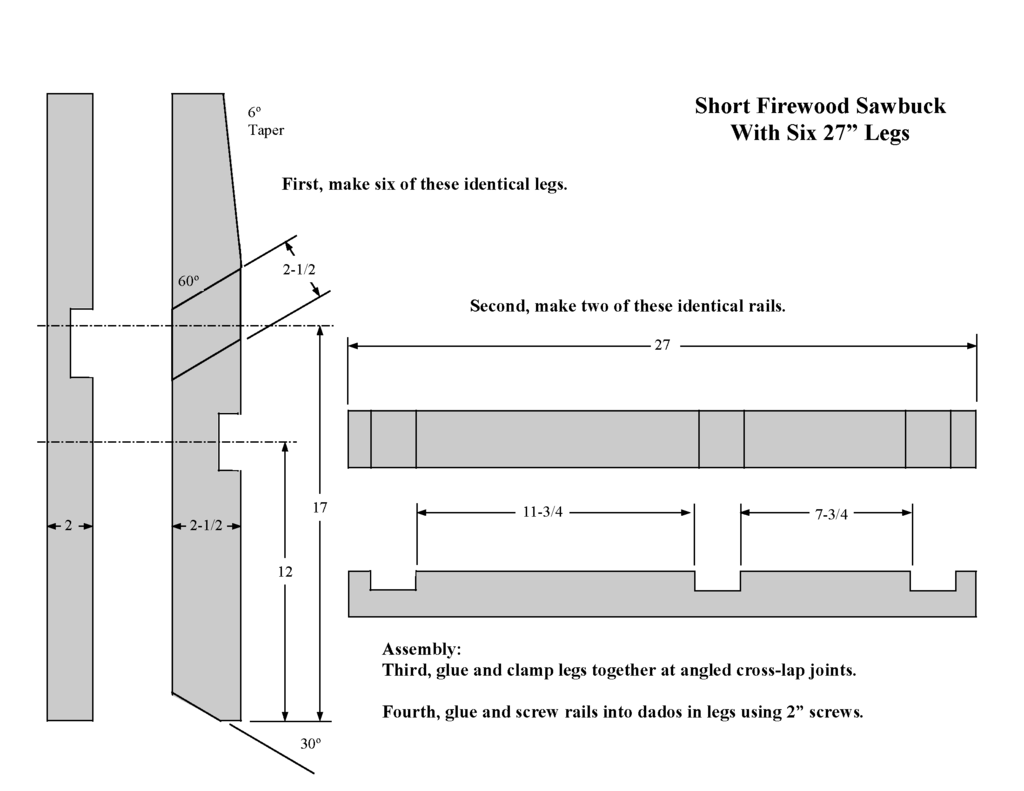

I could actually make one short sawbuck with 6 pieces: four identical 27" long uprights and two horizontal rails--all joined with lap joints for strength. Or I could add two more uprights and use the full 27" widths for the rails. WDYT?

Any other suggestions on what I could make with this good rough sawn hardwood? I can't bear seeing it go up the chimney.

What about short sawbucks? If you think about it, the idea of a sawbuck is to get logs off the ground. The higher the sawbuck is, the more work you have to do to lift it the long log on board, and the heavier the log, the worse it gets. Even if the log were only 14" off the ground, it seems like a short sawbuck would do the trick, especially for big logs.

I could actually make one short sawbuck with 6 pieces: four identical 27" long uprights and two horizontal rails--all joined with lap joints for strength. Or I could add two more uprights and use the full 27" widths for the rails. WDYT?

Any other suggestions on what I could make with this good rough sawn hardwood? I can't bear seeing it go up the chimney.