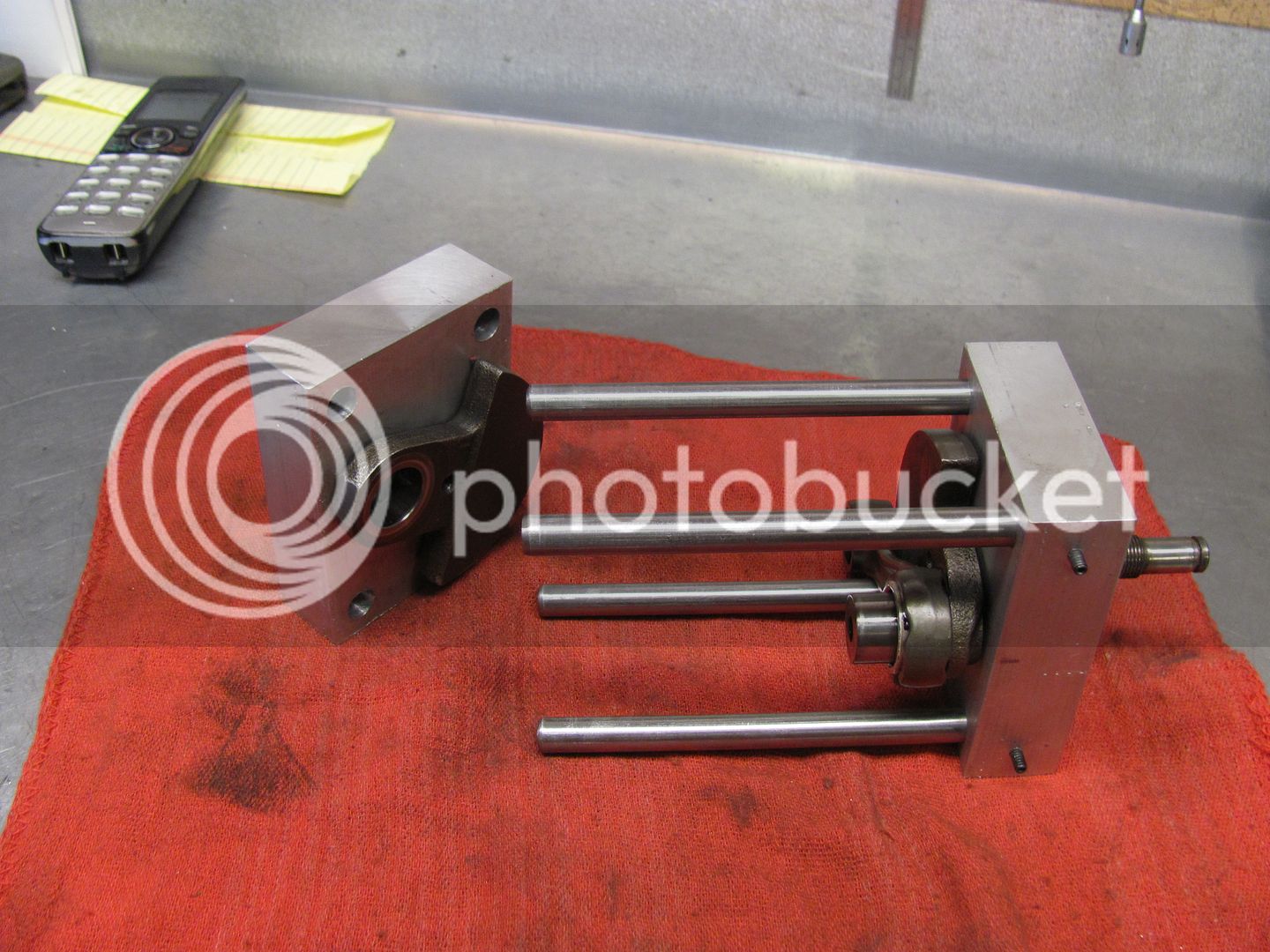

any decent motorcycle shop will have a single cylinder fixture to tune that up......and if ya friends with them let you use it on site however you got a lathe and a lead hammer......and I have seen the dial indicator! you can do it old school you might have to use a al wedge correct the counter weight spread....you make that tool....if you did you can true that crank no problem!It still has some runout.......now I gotta build a proper truing stand.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Any Idea What This Is???

- Thread starter Mastermind

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Dec 6, 2014

- Messages

- 21,212

- Reaction score

- 25,098

Nice work!!!

Mastermind

Work Saw Specialist

Forgot about this thread.....

Good read.

Magnum783

ArboristSite Guru

Why do you say forget about this thread did we have catastrophic engine fail. Usually that just means you are getting close. At least that is what I try to tell myself when I send an engine to the dyno and it speed disassembles. Just my experience.Forgot about this thread.....

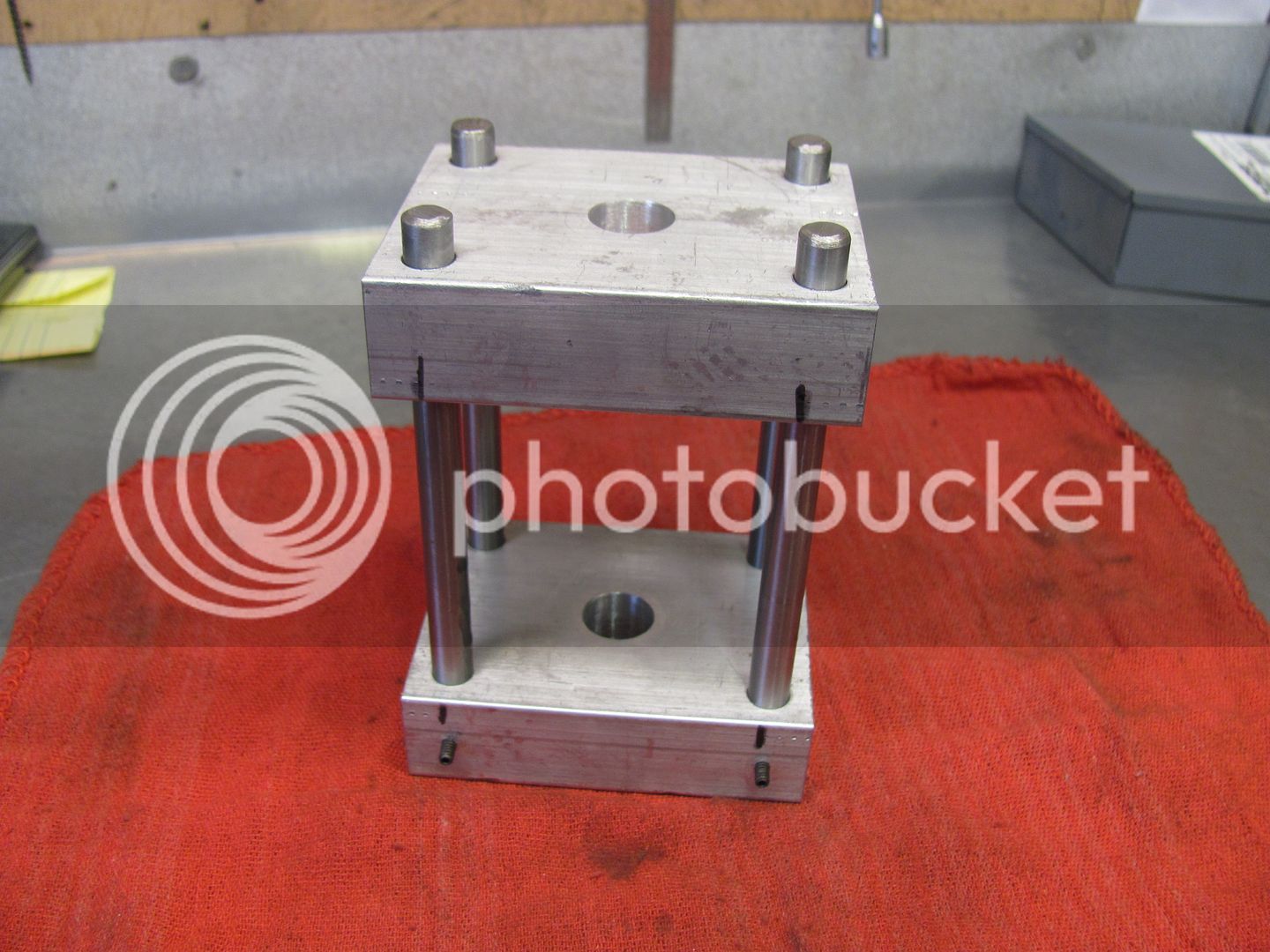

What about balance? I you put two different crank halves together do you need to check balance? SNOMOBILE shops can balance cranks. There might be some learning a on YouTube on how to build a crank balancer... Nice jig.

jar944

ArboristSite Operative

What about balance? I you put two different crank halves together do you need to check balance? SNOMOBILE shops can balance cranks. There might be some learning a on YouTube on how to build a crank balancer... Nice jig.

Putting the same weight piston back in does not change balance. Actually you can't balance a single cylinder without a counter balancer built into the engine. Singles are "balanced" using a balance factor of approximately 50-70% of the reciprocating weight. All it does is change the rpm range where the maxium felt vibrations occur.

If you could truly balance a chainsaw engine you wouldn't need AV setups.

You can balance single cylinders, it's done all the time. My main point was your taking two separate halves of a crank and putting them together to make one. There's a chance that balance could be off by a significant amount.Putting the same weight piston back in does not change balance. Actually you can't balance a single cylinder without a counter balancer built into the engine. Singles are "balanced" using a balance factor of approximately 50-70% of the reciprocating weight. All it does is change the rpm range where the maxium felt vibrations occur.

If you could truly balance a chainsaw engine you wouldn't need AV setups.

tree monkey

Addicted to ArboristSite

proper term is trued

jar944

ArboristSite Operative

You can balance single cylinders, it's done all the time. My main point was your taking two separate halves of a crank and putting them together to make one. There's a chance that balance could be off by a significant amount.

You can change the rpm range where a single cylinder vibrates, but you cannot truly balance it without two counter rotating balance shafts. The only way to change the balance factor of a engine is to remove or add weight to the rotating or reciprocating assembly. Just assembling the crank halves does not effect balance. Shops that "balance" 2t singles or 4t singles w/o counter balancers are just changing the balance factor. Be that change back to stock because of a different weight piston, or because of a change in primary rpm usage.

Here is a great article on engine balance.

www.tonyfoale.com/Articles/EngineBalance/EngineBalance.pdf

And a calculator than graphs the out of balance forces on a crankshaft

http://www.tonyfoale.com/progs/BF.exe

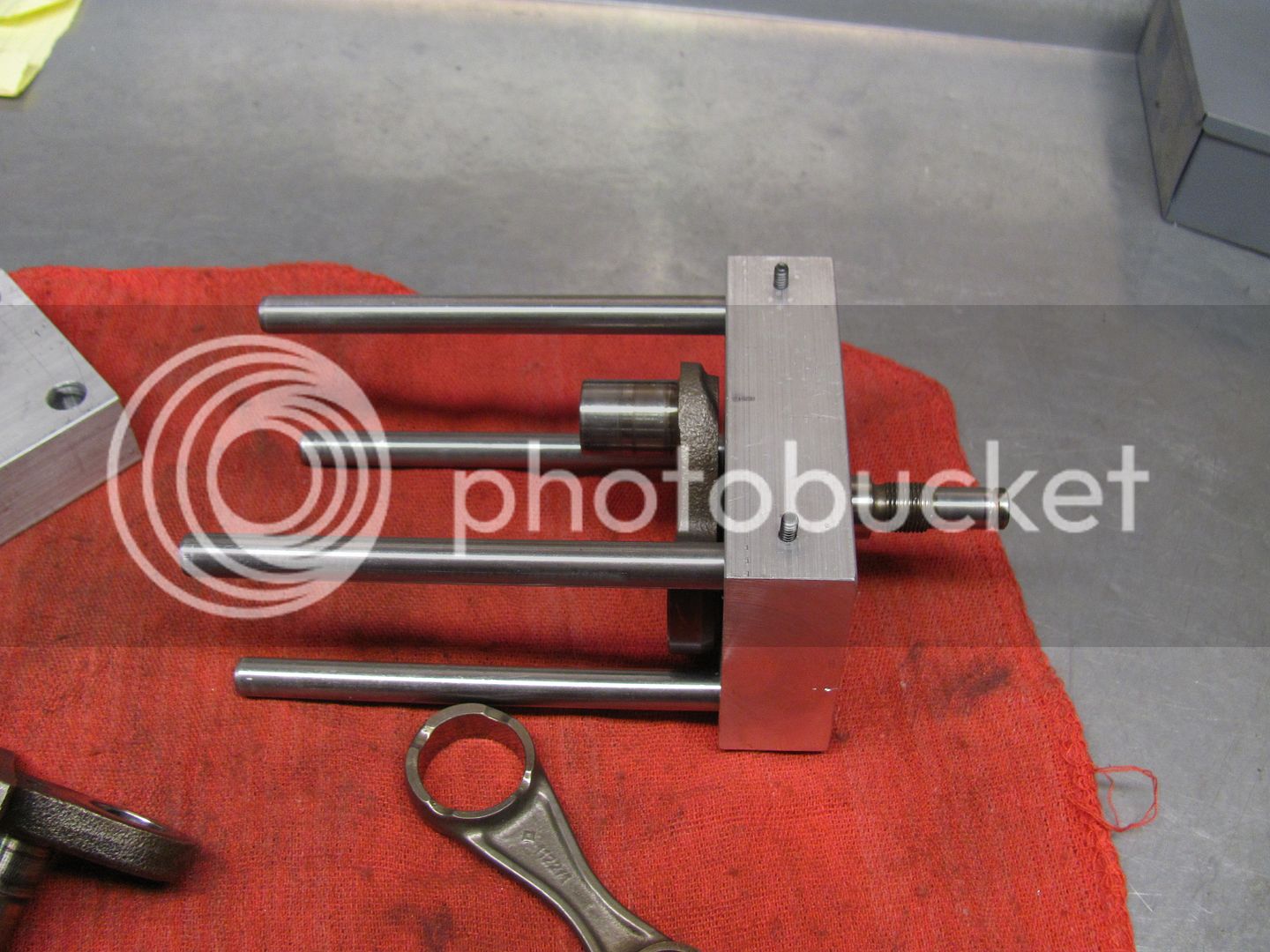

Like tree monkey mentioned I think what you are talking about is truing a crank, which does need to occur after the halves are pressed together, however the jig should remove the need if its built correctly

No I'm not talking about truing, I'm talking about balance. If you replace half of the crank with another half you could be increasing or decreasing the total assembled counter balance weight from the variations in crank web weights. The reciprocating mass can be assumed to remain constant because your using the same weight piston and rod. Maybe it's a non issue but that would be highly dependent on how tight the manufactures tolerances are when they manufacture the cranks. A few grams could make a significant impact on the natural frequency of the rotating mass. I understand the engine won't be truly balanced for all RPMs.

Thanks for the link I'll read.

Thanks for the link I'll read.

tickbitintn

ArboristSite Operative

that tool would be MUCH more useful if rod kits were available for saws......

instead of having to buy a complete crank for more $

instead of having to buy a complete crank for more $

Mastermind

Work Saw Specialist

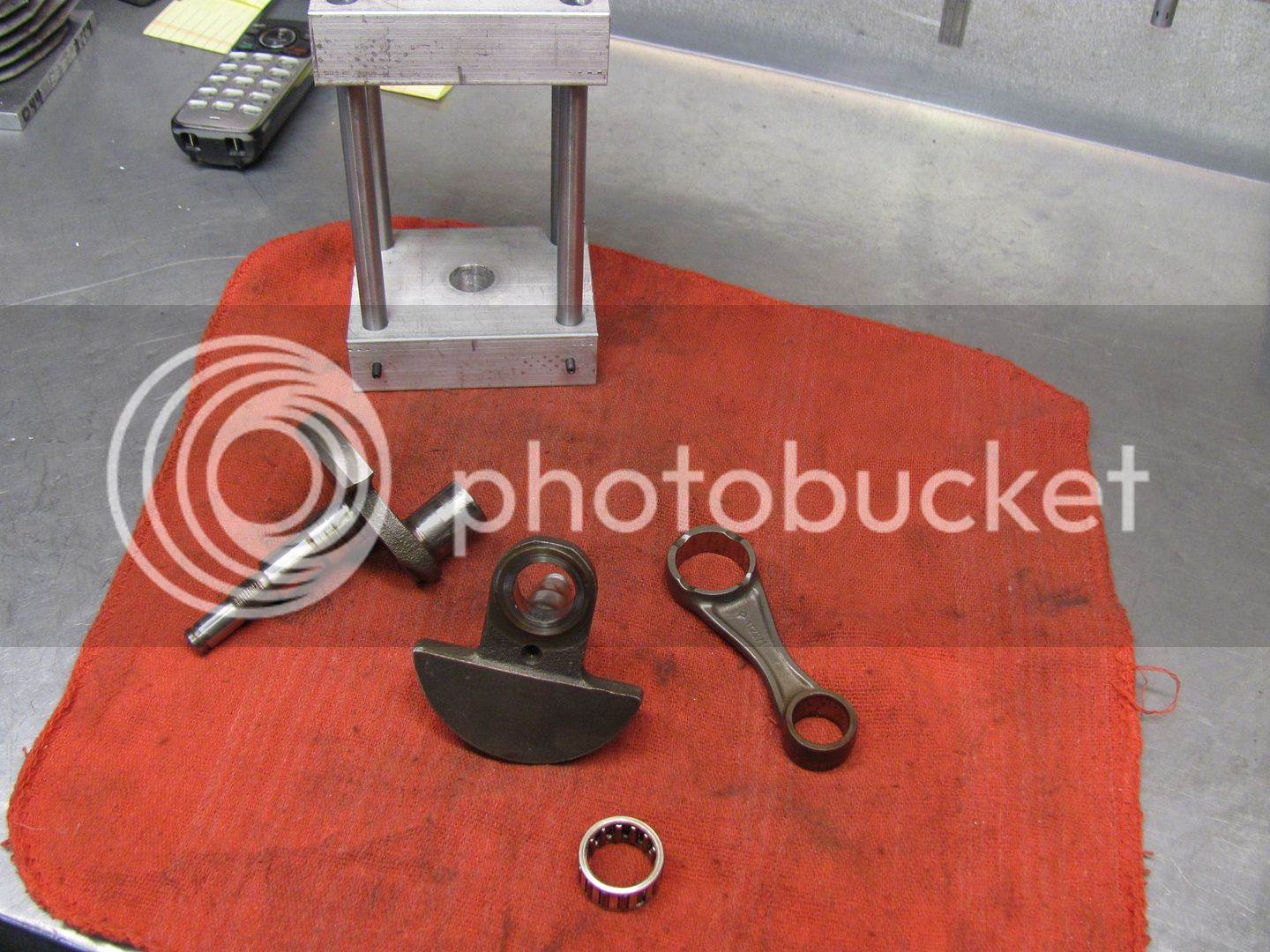

I built it to fix broken cranks.

If the bearing is shot.....the bearing surface on the crank is normally rough.

If the bearing is shot.....the bearing surface on the crank is normally rough.

tacomatrd98

ArboristSite Guru

He could be refering to the actual weight of the crank halves. Different saws use different cranks. Some older 044 cranks are thinner then their newer counterparts. A 10 mm 044 crank is lighter than a 12mm unit, and not just because of the rod. A 346 and 350 husky have very similar cranks but a 350 the crank weights look identical where as the 346 has different size and I assume diff weight crank halves for clutch and flywheel side. 064 and early 066 cranks are the same part number but I have seen a large variation in counterweight style, width, rod design etc depending on production date and application.

jar944

ArboristSite Operative

No I'm not talking about truing, I'm talking about balance. If you replace half of the crank with another half you could be increasing or decreasing the total assembled counter balance weight from the variations in crank web weights. The reciprocating mass can be assumed to remain constant because your using the same weight piston and rod. Maybe it's a non issue but that would be highly dependent on how tight the manufactures tolerances are when they manufacture the cranks. A few grams could make a significant impact on the natural frequency of the rotating mass. I understand the engine won't be truly balanced for all RPMs.

Thanks for the link I'll read.

Ahh, I didn't realize you were talking about replacing one side with a new/different crank half.

tickbitintn

ArboristSite Operative

I built it to fix broken cranks.

If the bearing is shot.....the bearing surface on the crank is normally rough.

Rod Kit Would be rod, bearing and crank pin. Most Single Cyl Engines In Powersports Applications Offer These One Piece Rod Kits Much Cheaper Than A Replacement Crank Assembly Would Cost.

Mastermind

Work Saw Specialist

Rod Kit Would be rod, bearing and crank pin. Most Single Cyl Engines In Powersports Applications Offer These One Piece Rod Kits Much Cheaper Than A Replacement Crank Assembly Would Cost.

A two piece crank ain't got a pin......

tickbitintn

ArboristSite Operative

A two piece crank ain't got a pin......

i learned something new then....

i thought they were two halves with a pin pressed in between them.... so 3 piece actually

have never taken one apart, or seen one apart ( probably why )

i try to keep up with your threads i always learn stuff, and stuff...

nice fixture by the way. thanks for sharing.

pressing them part way then truing, then press, then true yields faster end results from my experience with m/c and four wheeler cranks.

Similar threads

- Replies

- 17

- Views

- 688

- Replies

- 3

- Views

- 344