Easy question if you were new to sharpening!

Same brand of chain? Same saw? Same wood? Same grinder wheel?

Are you using a fixed offset or progressive depth gauge settings?

Sure that you did not space out and use a different size wheel? Grinding to a different depth? What do your side plates look like?

These are things I would take a second look at.

Philbert

I pulled the one I was running off my 036 today and sharpened it. Normally I just swap loops and sharpen when I have time, but I had the no self feed issues with all the ones I had sharpened the last time I had done them.

At the same time I sharpened a loop for a customer's 440.

The loop on the 440 cuts great (had to test the repairs we did, otherwise i wouldnt just use a customer's saw!) while the loop for mine doesnt.

Both are Stihl chain, the 440 was a skip 84 drivers, my chains are full complement, 66 drivers.

I have a mix of semi chisel and chisel, issue seems to be with both. All the chains I have are Stihl.

I thought it was maybe the depth gauges, but one loop I have them down the the minimum mark while I am still 40-50% on the teeth.

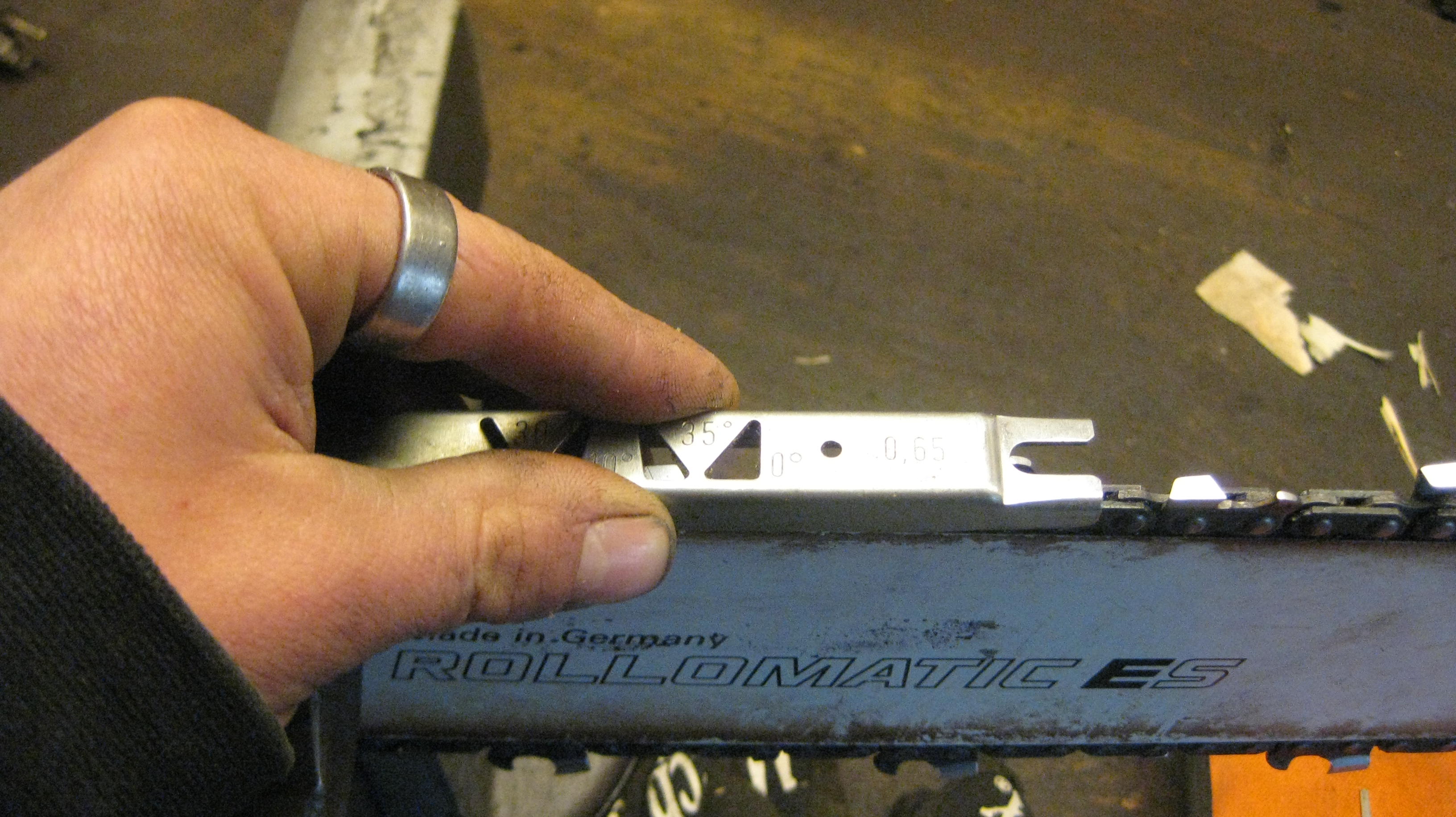

I use a grinder for the rakers. I use the tool shown in the pic to adjust the grinder 's depth stop. I grind the depth gauges on a slope.

I haven't changed anything and I've been using the same machines for a few years so it's got me puzzled.

Not that I'm an expert by any means, but I've never had to fight the saw like I am now. I normally can get a chain to cut like brand new.

The bar is ok, I just ground the rails yesterday even though it looked fine.

Haven't tested on other saws, I'll try that.

I'll try to get some pics later today.