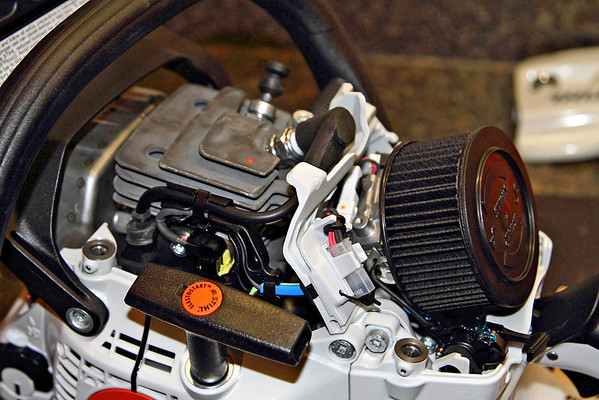

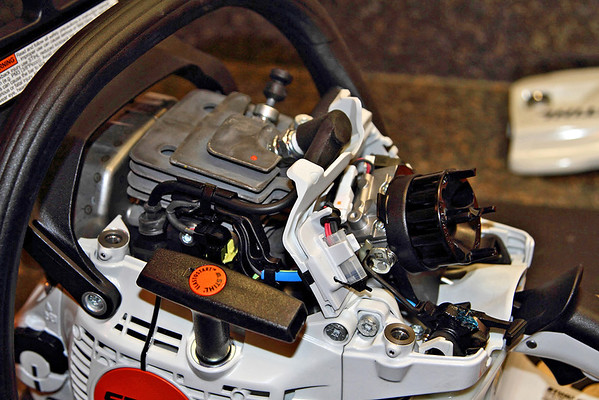

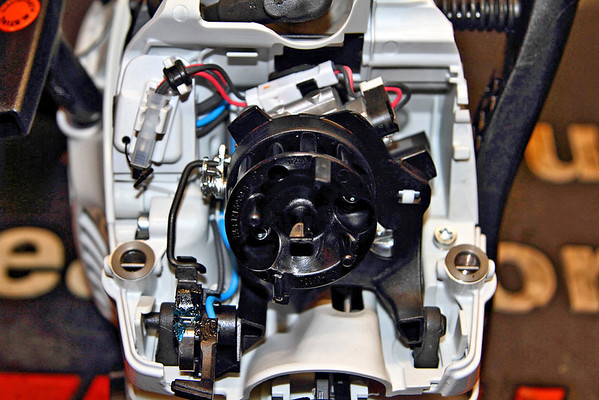

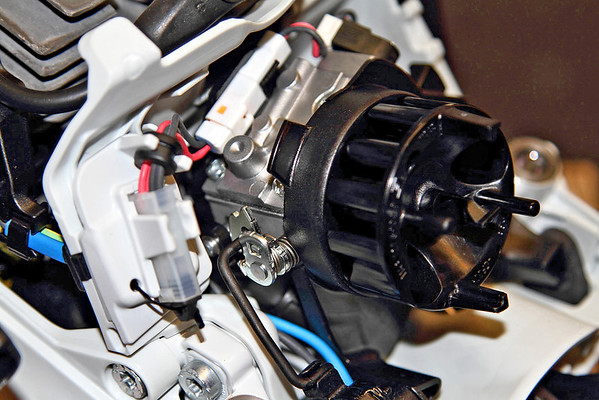

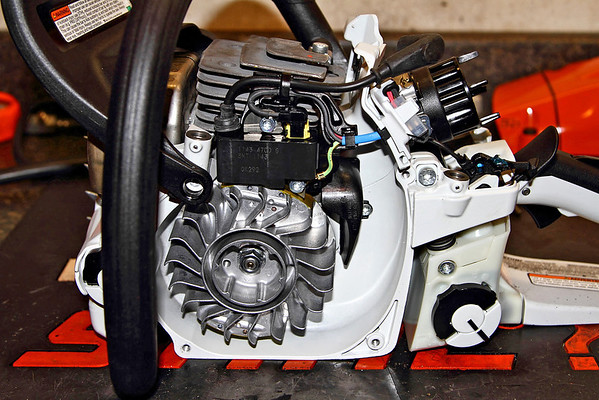

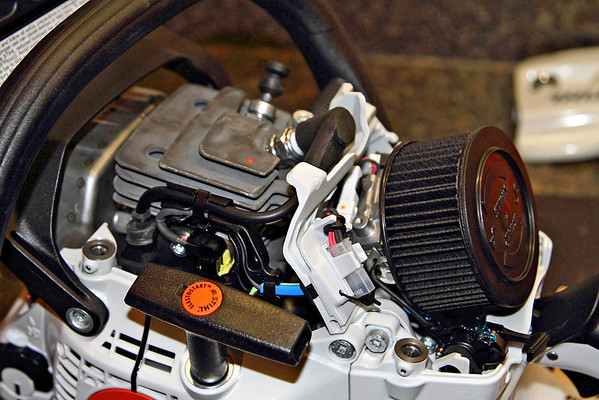

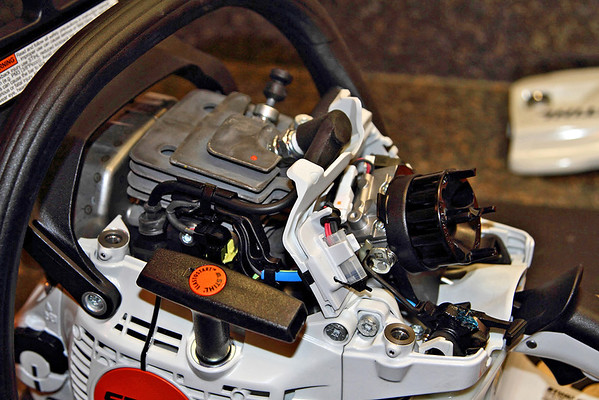

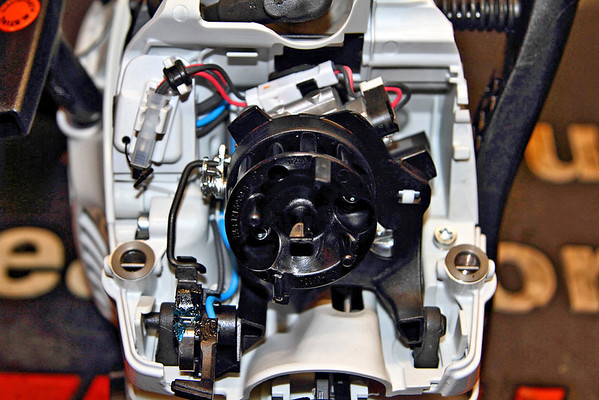

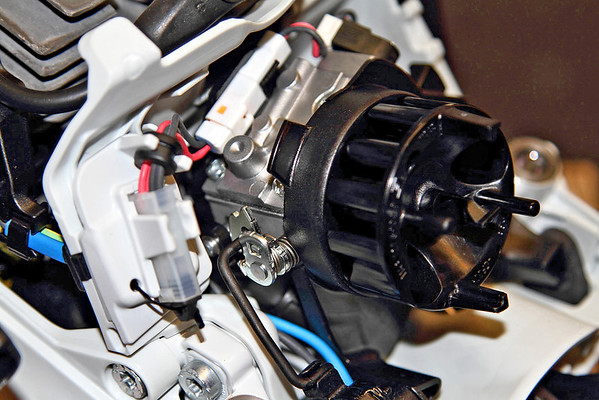

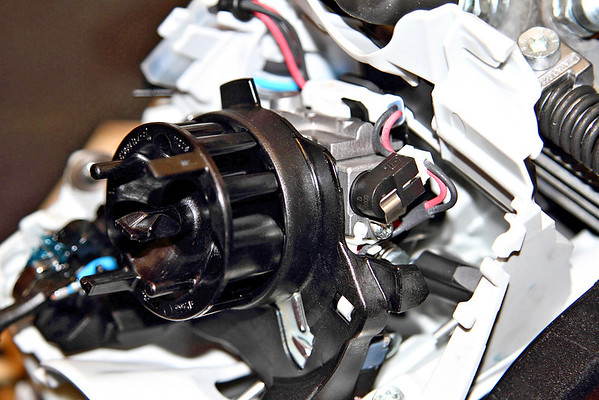

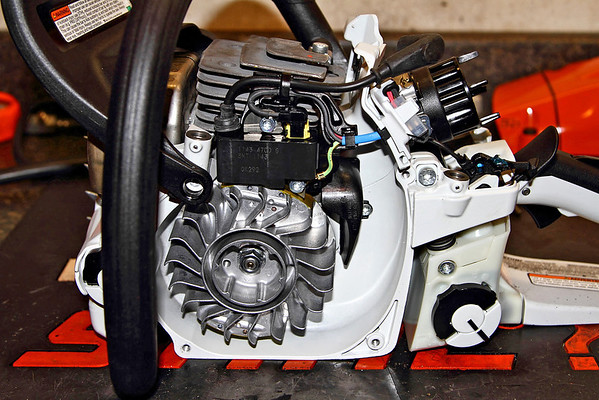

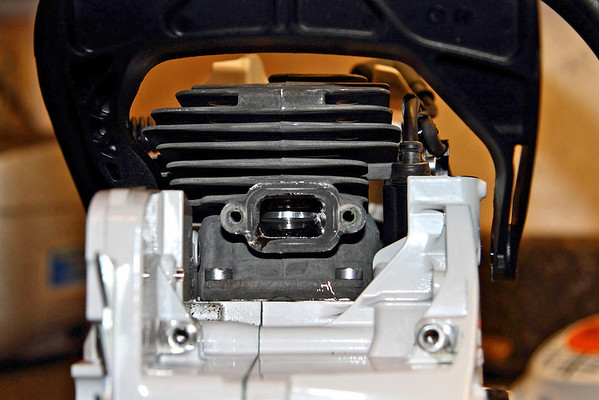

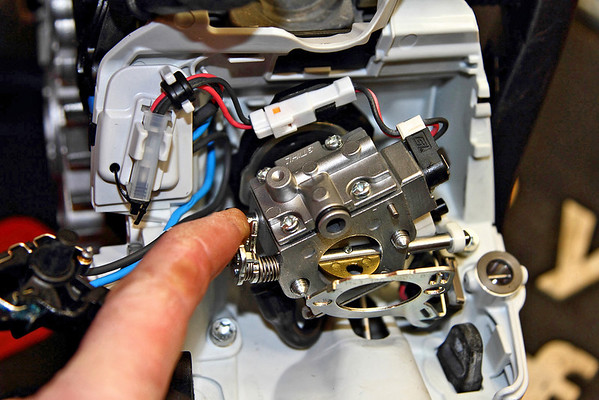

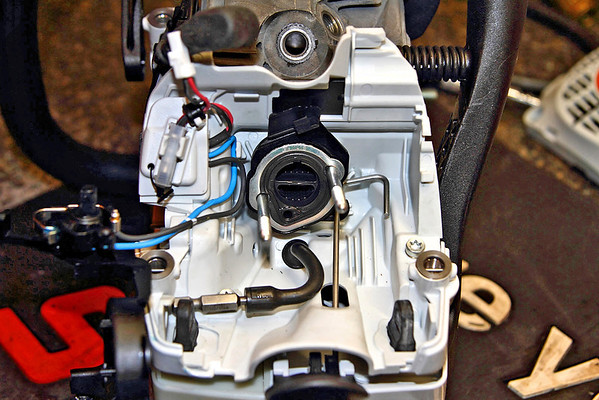

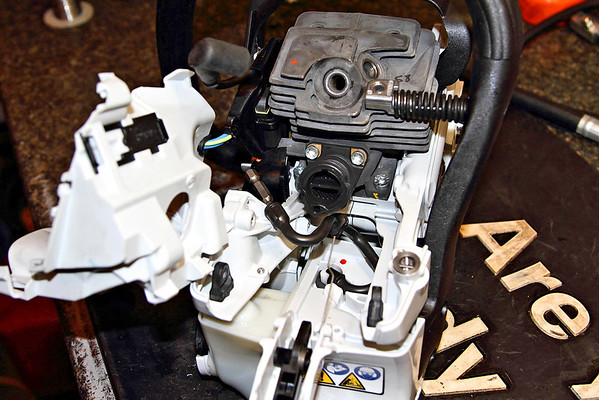

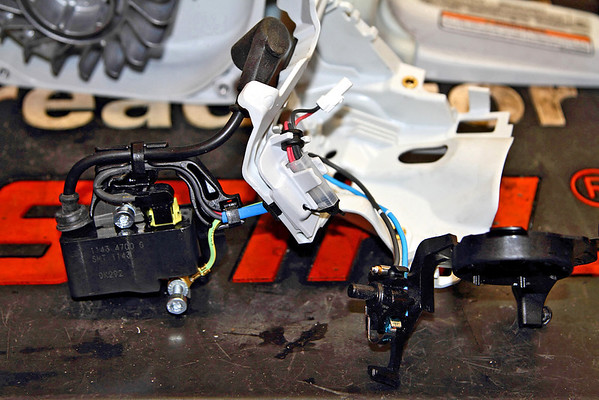

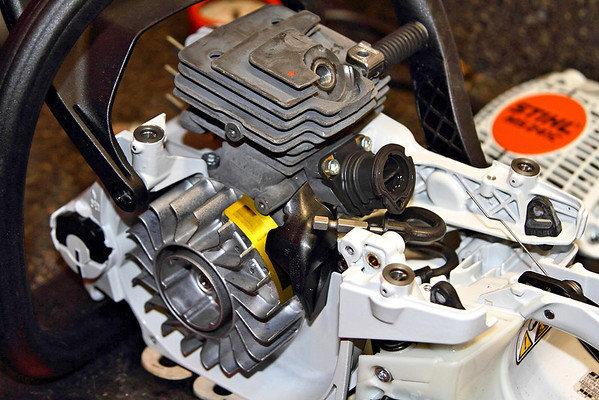

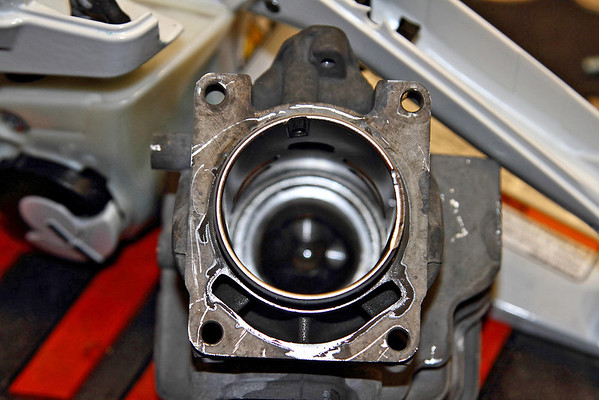

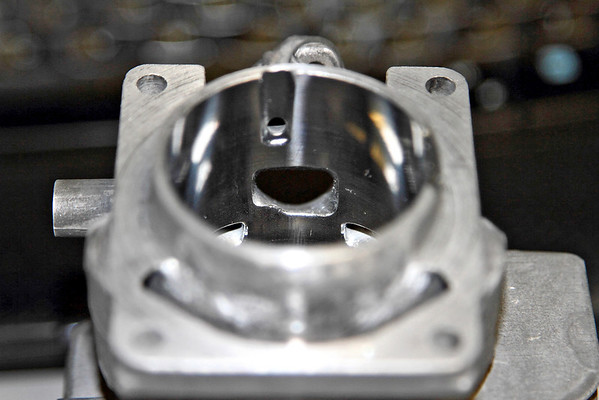

What a fine little saw this is. The design is a cross between a 261C and a 461. The quad transfers are all fed from the front of the cylinder, just like the 461 and 661. The rest of the saw is basically 261C. Quality is very nice. I was disappointed to see several self tapping screws, such as those holding the intake manifold to the cylinder and the coil to cylinder bolts. Not a big deal though.

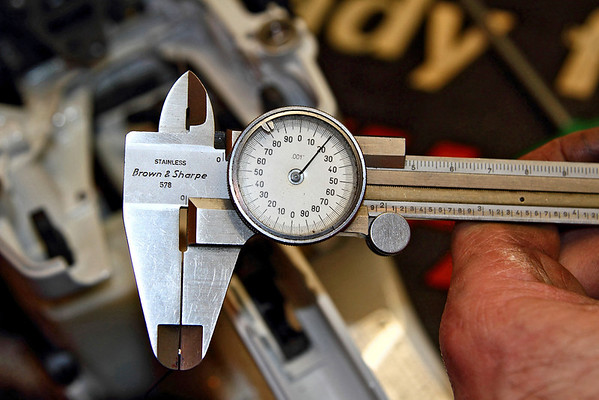

Compression 155

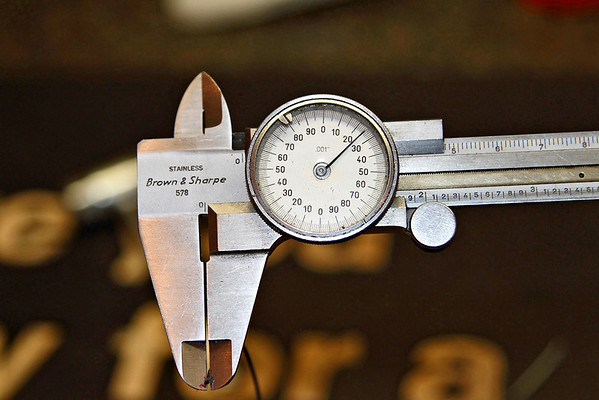

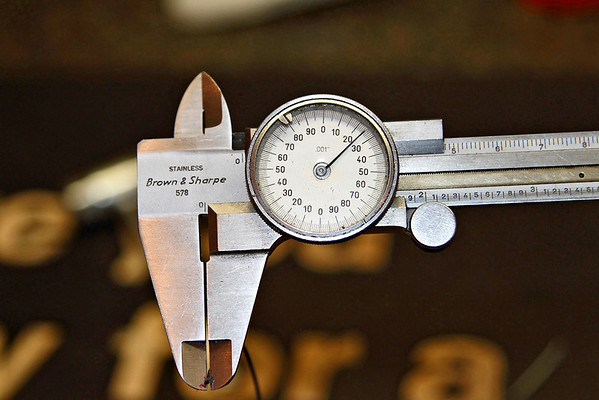

Squish .025"

I'll have another one of these shortly for a side-by-side comparison. I'm looking for a test log, but wanted to get going on this thing tonight.

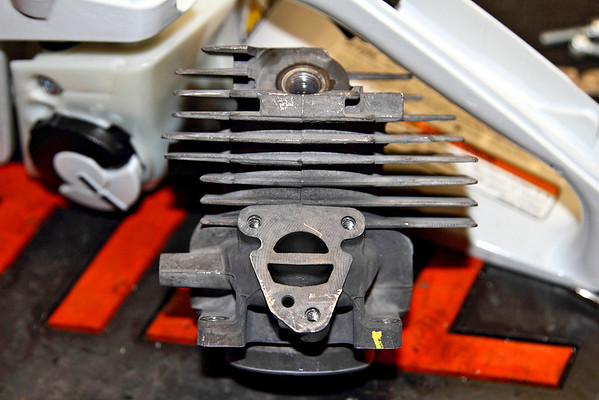

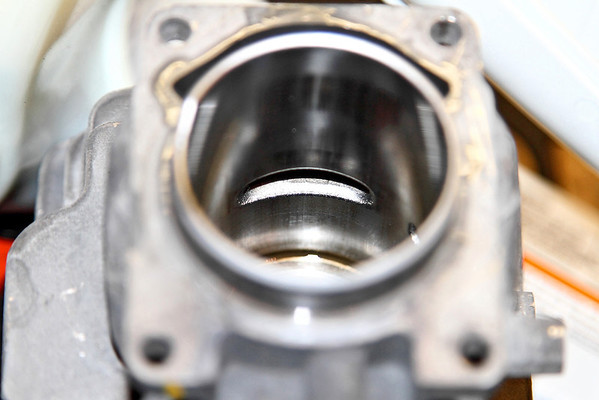

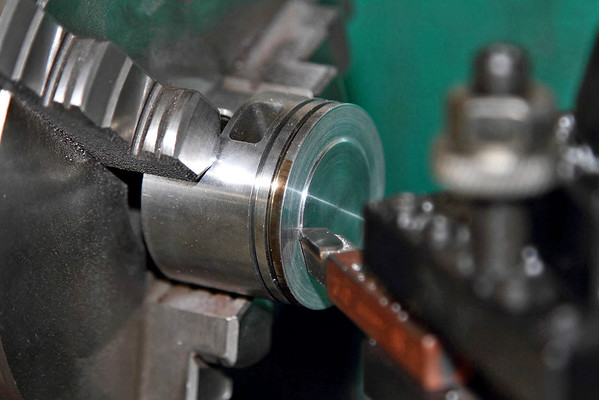

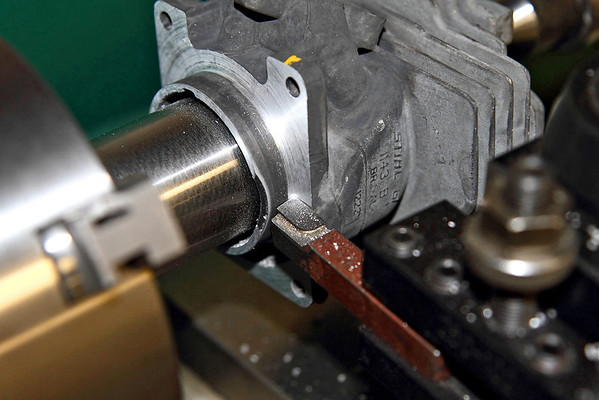

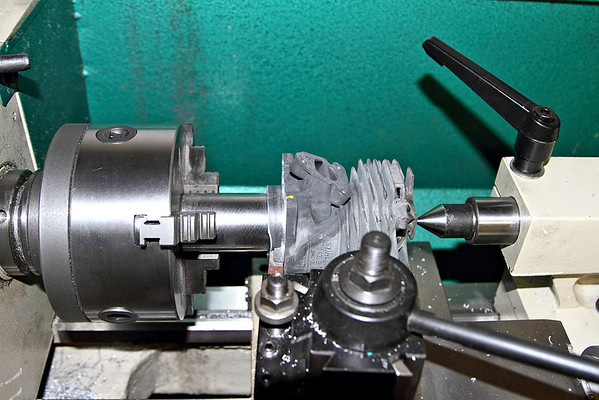

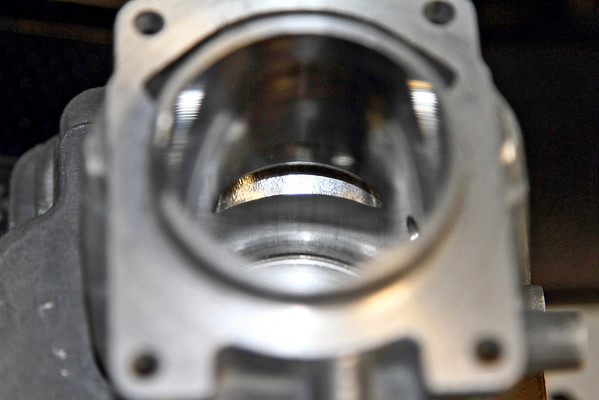

Before measuring port timing, I first cut a .020" popup on the piston and set the squish to .020". The crown was not thick enough for a taller popup.

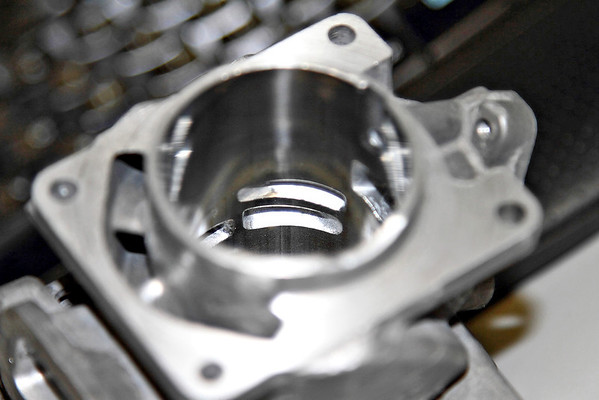

Before porting

Exhaust - 110°

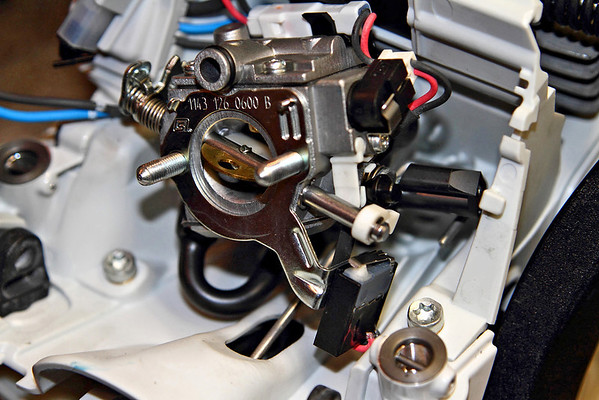

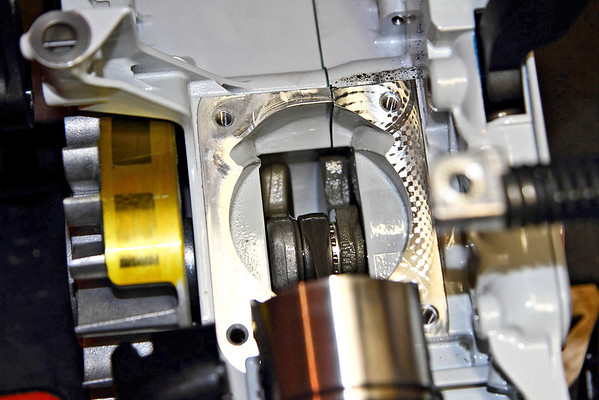

Transfers - 123° (angled significantly)

Intake - 71°

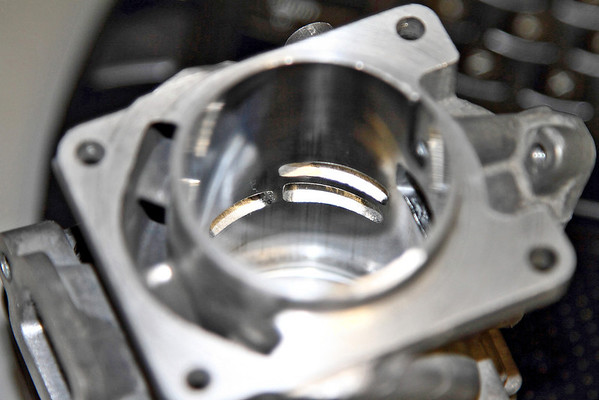

After porting

Exhaust - 107°

Transfers - 123° (flat)

Intake - 77°

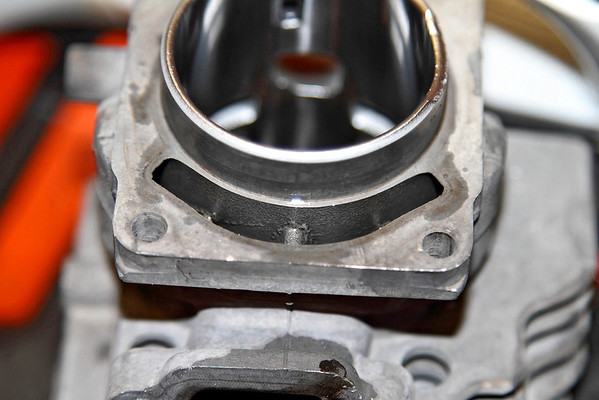

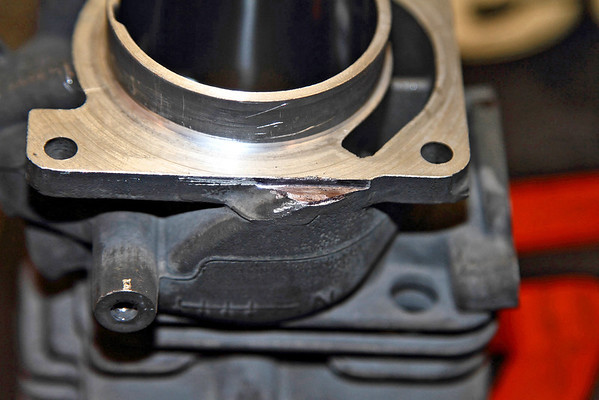

The exhaust was widened significantly to 70% of the bore.

The intake was widened slightly, limited by the narrow skirt found on most strato saws.

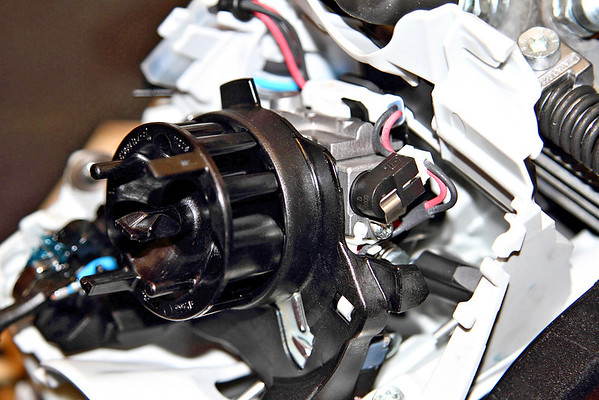

The transfers are angled significantly from the factory. I made them flat and slightly widened them. This significantly increases the time and area.

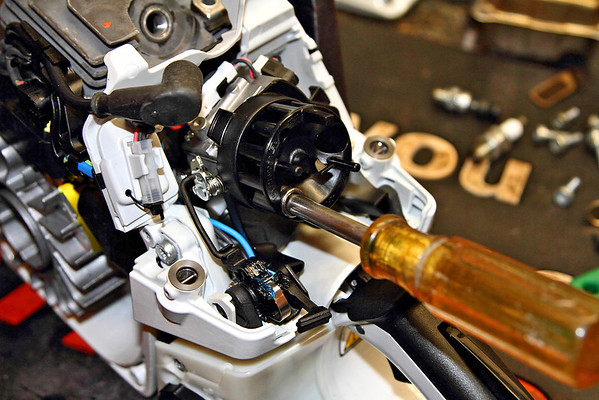

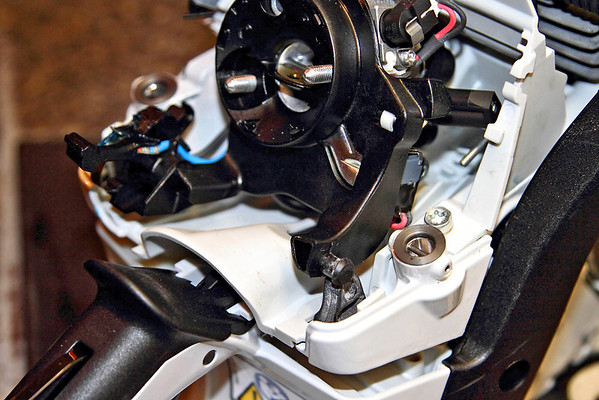

The strato ports were widened slightly.

A large lip at the entrance to the transfer intake duct was removed.

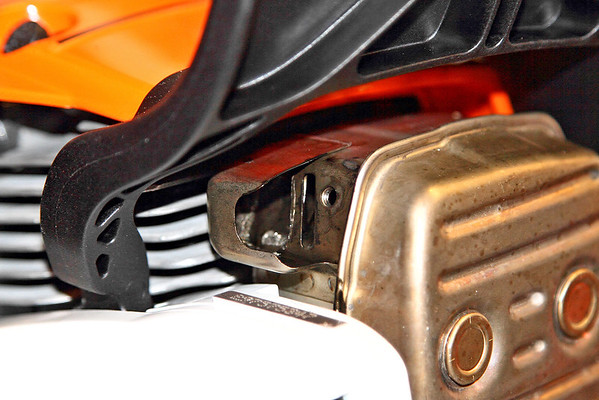

I opened the original exhaust opening on the muffler as much as could be covered by the deflector. I added a second port, using the gills I have on most 261s that I've done.

I removed the baffles from the filter adapter.

It idles perfectly, hits WOT instantly, and returns to idle fast. The saw feels like a little monster. I can't wait to cut with it.

I HOPE TO MAKE A VIDEO TOMORROW!!!

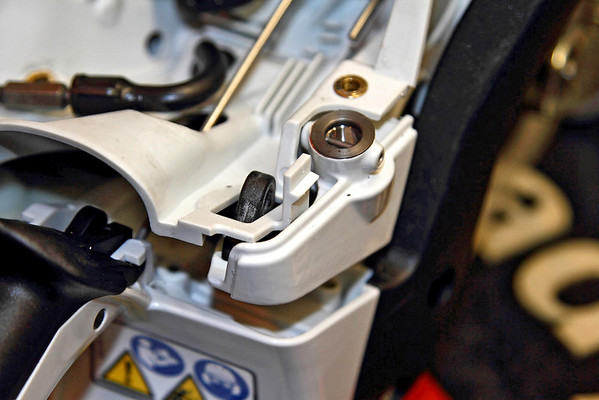

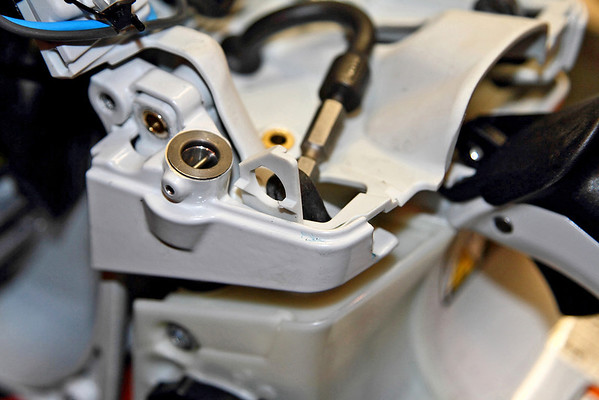

Plastic bar cover.

New style plugs. I like them.

Compression 155

Squish .025"

I'll have another one of these shortly for a side-by-side comparison. I'm looking for a test log, but wanted to get going on this thing tonight.

Before measuring port timing, I first cut a .020" popup on the piston and set the squish to .020". The crown was not thick enough for a taller popup.

Before porting

Exhaust - 110°

Transfers - 123° (angled significantly)

Intake - 71°

After porting

Exhaust - 107°

Transfers - 123° (flat)

Intake - 77°

The exhaust was widened significantly to 70% of the bore.

The intake was widened slightly, limited by the narrow skirt found on most strato saws.

The transfers are angled significantly from the factory. I made them flat and slightly widened them. This significantly increases the time and area.

The strato ports were widened slightly.

A large lip at the entrance to the transfer intake duct was removed.

I opened the original exhaust opening on the muffler as much as could be covered by the deflector. I added a second port, using the gills I have on most 261s that I've done.

I removed the baffles from the filter adapter.

It idles perfectly, hits WOT instantly, and returns to idle fast. The saw feels like a little monster. I can't wait to cut with it.

I HOPE TO MAKE A VIDEO TOMORROW!!!

Plastic bar cover.

New style plugs. I like them.

. A true lil pro saw! A little pricey for 40cc's but the service life makes them great value. Quality is remembered well after price is forgotten. Stihl really thought about this one and hit the nail on the head. It's easy to fall in love with this lil cutey, since getting one the ms261 takes back seat... Nice pics btw Brad! Thanks 4 sharing and feeding our CAD.

. A true lil pro saw! A little pricey for 40cc's but the service life makes them great value. Quality is remembered well after price is forgotten. Stihl really thought about this one and hit the nail on the head. It's easy to fall in love with this lil cutey, since getting one the ms261 takes back seat... Nice pics btw Brad! Thanks 4 sharing and feeding our CAD.