Jakers

Owner - Arbor Jake's Tree Service, LLC

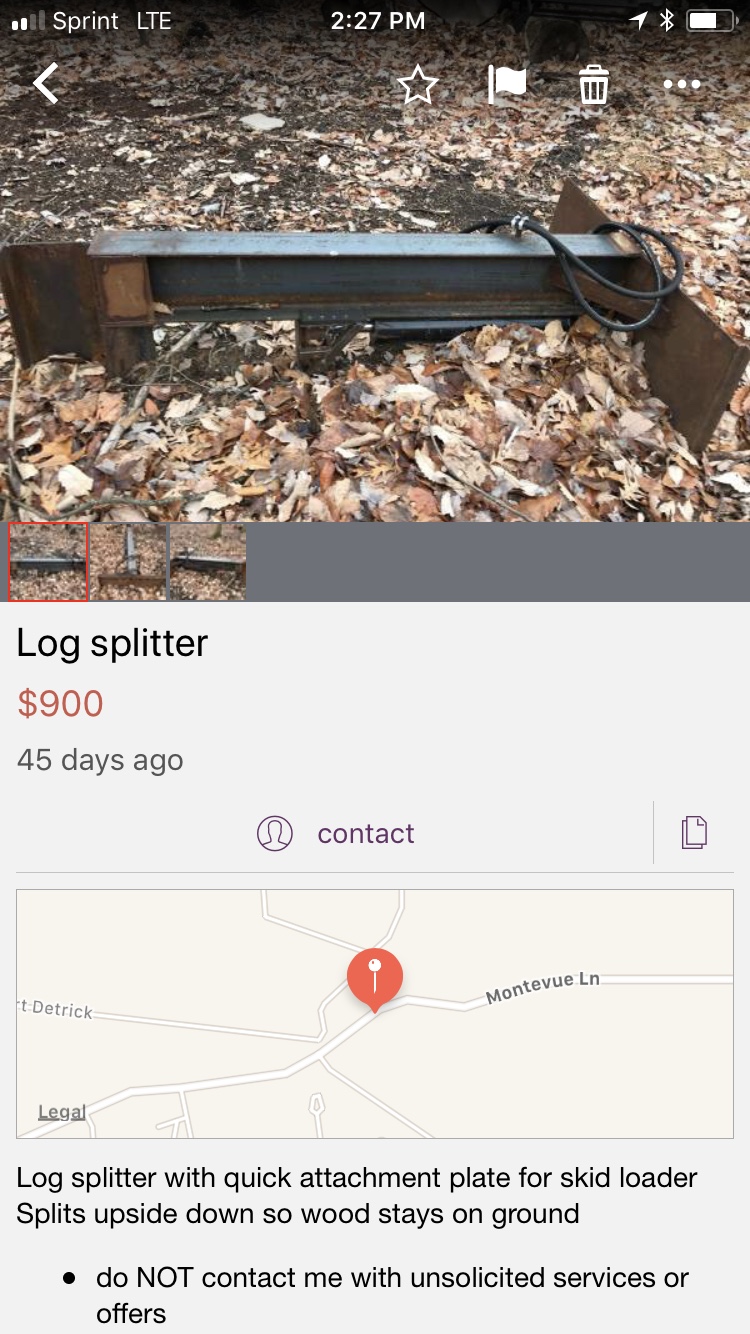

Just cruising the local craigslist ads and came across this (picture below). in all reality it's exactly what I've been looking for but I'm a little over-spent at the moment. Any way, on closer inspection I realized the cylinder was mounted backwards from most and that the whole beam and wedge moved while the cylinder and push plate stayed put. I know it seems like a complicated way to make a moving wedge splitter but this fixes one of the biggest problems I've always seen with the moving wedge design. The wedge can be as thin as a standard fixed wedge for cutting through the crotches and stringy stuff or designed however the user desires. I think having an adjustable 4 way on this design would be difficult but for a tall, single split in this configuration it is perfect. I've been considering building a skidsteer splitter for some time now but the biggest reasons I haven't are the wedge designs that are common are either too wide for big nasty tree service wood or push the wood away requiring so much extra moving around and tearing up the ground. I have always known i wanted a horizontal splitter as this one is designed, the long ones seem like they would be extremely twitchy and hard to feather softly to be efficient. I don't believe this idea is will replace the standard designs for production splitters but none the less, useful in the right situation. At any rate, I just thought I'd throw this out there for others to view and place in the old knowledge bank of ideas.