Johnsobri's Stihl 028 Super Rebuild

Hello, just wanted to start a thread showing me rebuilding my dream saw.

I know it's not a big 100cc+ saw but that isn't what I wanted to do(yet at least!). I grew up running my fathers 028 AVEQ and fell in love with the "round butt" Stihl's as some people call them. With my father having an 028 I was always on the lookout for the same but I really wanted an 028 Super. Couldn't let my old man show me up so I needed a more powerful saw than him. My fathers saw has always treated us well and to this day is a great runner and looker!

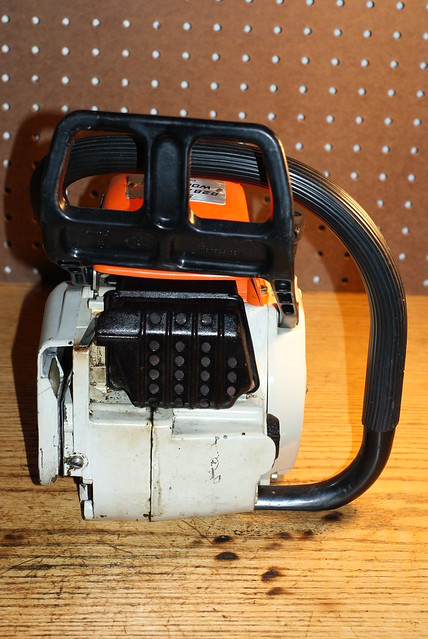

I was selling an 026 that I flipped and as I always do I put that I would trade for chainsaws. A guy called and we worked out a deal to where I got cash and an 028 Super. Sweet! So that's how I came to acquire this:

The good:

Recoil Side by llzebraheadll, on Flickr

Clutch Side by llzebraheadll, on Flickr

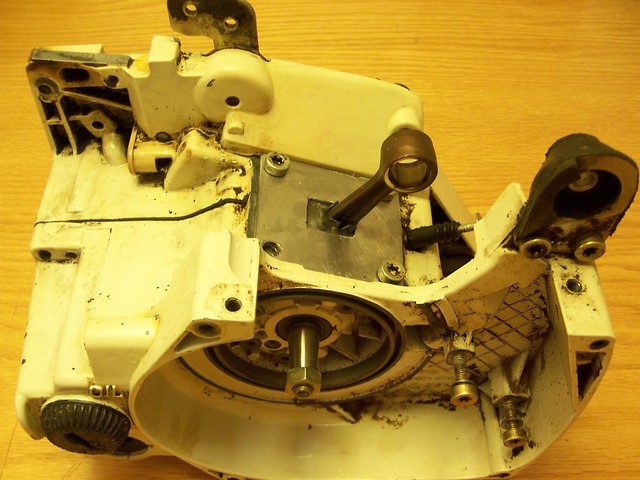

Bottom by llzebraheadll, on Flickr

Top cover by llzebraheadll, on Flickr

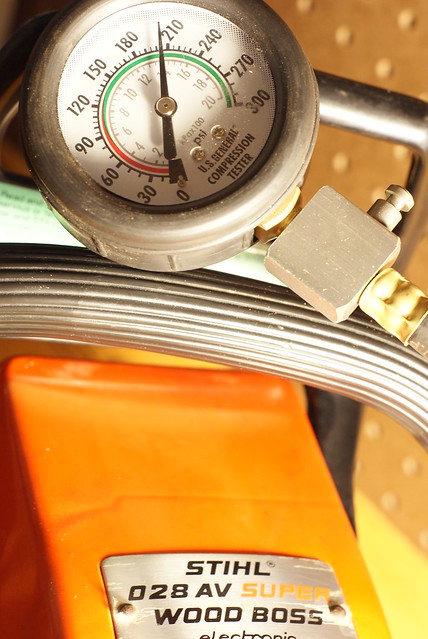

The bad:

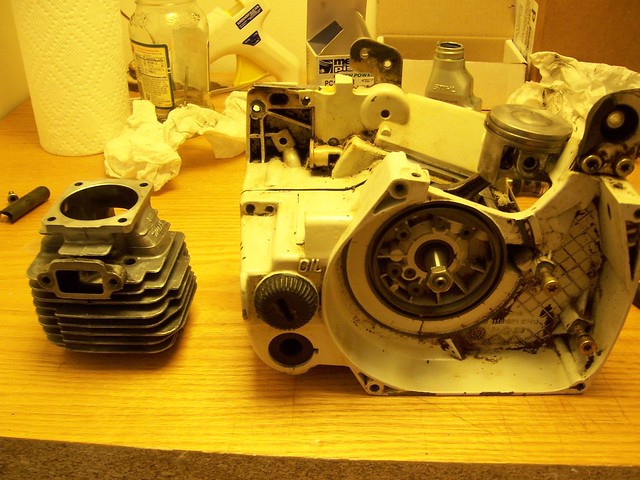

Cylinder by llzebraheadll, on Flickr

I have already torn the saw down and it's waiting to be cleaned.

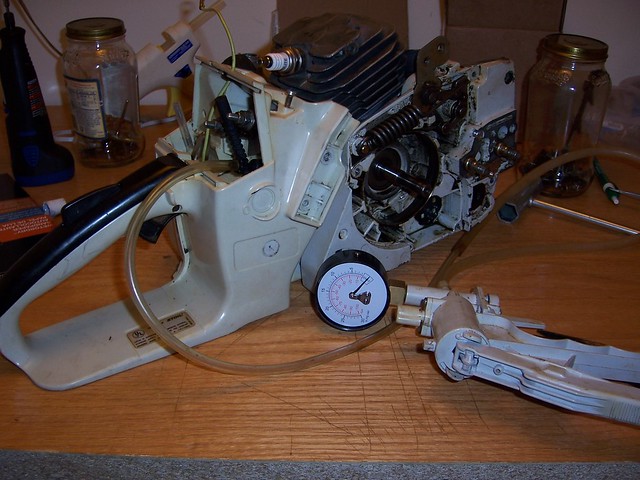

When I was breaking it down I decided to do a vacuum test to see if I could find what caused it to score the piston. Looks like the impulse line was the reason for the lean condition.

I have already ordered some parts. Since I knew I was going to tear it down I went ahead and ordered the fuel & impulse line, intake boot, and oil seals. I did order a meteor piston in hopes that the cylinder can be saved.

I haven't taken the cylinder off yet because I want to clean the crankcase up so I don't have any problems with chips/dirt falling into it.

I don't know if I am going to go the whole painting route just yet. I am going to wait and see how I feel about that a little later.

I hope to detail the process of this rebuild to help keep me going in the right direction and to maybe help some other people out who are doing the same thing.

Hope you enjoy the build!

Hello, just wanted to start a thread showing me rebuilding my dream saw.

I know it's not a big 100cc+ saw but that isn't what I wanted to do(yet at least!). I grew up running my fathers 028 AVEQ and fell in love with the "round butt" Stihl's as some people call them. With my father having an 028 I was always on the lookout for the same but I really wanted an 028 Super. Couldn't let my old man show me up so I needed a more powerful saw than him. My fathers saw has always treated us well and to this day is a great runner and looker!

I was selling an 026 that I flipped and as I always do I put that I would trade for chainsaws. A guy called and we worked out a deal to where I got cash and an 028 Super. Sweet! So that's how I came to acquire this:

The good:

Recoil Side by llzebraheadll, on Flickr

Clutch Side by llzebraheadll, on Flickr

Bottom by llzebraheadll, on Flickr

Top cover by llzebraheadll, on Flickr

The bad:

Cylinder by llzebraheadll, on Flickr

I have already torn the saw down and it's waiting to be cleaned.

When I was breaking it down I decided to do a vacuum test to see if I could find what caused it to score the piston. Looks like the impulse line was the reason for the lean condition.

I have already ordered some parts. Since I knew I was going to tear it down I went ahead and ordered the fuel & impulse line, intake boot, and oil seals. I did order a meteor piston in hopes that the cylinder can be saved.

I haven't taken the cylinder off yet because I want to clean the crankcase up so I don't have any problems with chips/dirt falling into it.

I don't know if I am going to go the whole painting route just yet. I am going to wait and see how I feel about that a little later.

I hope to detail the process of this rebuild to help keep me going in the right direction and to maybe help some other people out who are doing the same thing.

Hope you enjoy the build!