Stihlman441

Addicted to ArboristSite

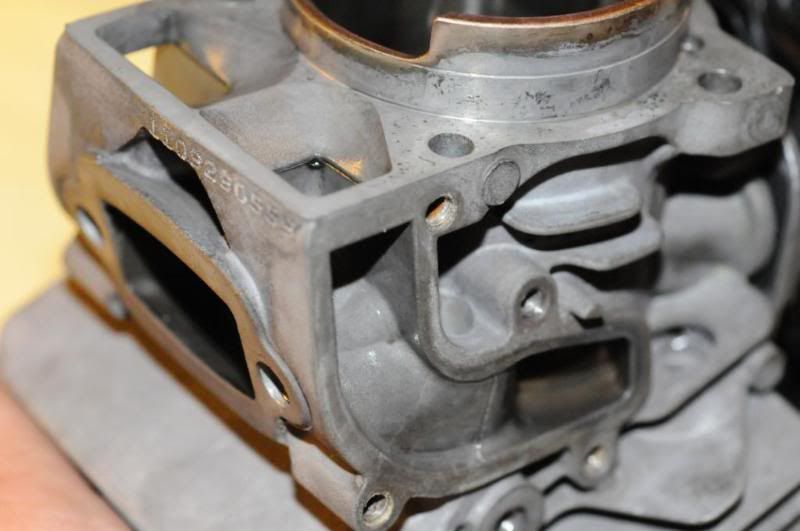

Brad, all these various stratos are a bit different and take a slightly different approach to each of them. As I said 'on my saw' I couldn't make the strato ports any bigger. This is a Husky 450 that is based upon the 445 - the engineers had trimmed every bit of port work they could to open it up. In fact, the strato butterfly was a big 16mm, but the manifold was only 13.5mm. It became clear why it was only 13.5mm after I calculated the area of the strato ports in the cylinder, that's all it needed.

However, the piston did partially block the ports in the cylinder, so I reworked the piston so that the whole system could flow like it was designed to. I even trimmed back the ends of the pin boss so that the air could get past it.

Back to the fuel issue. It is real easy to get more fuel in a engine, just richen the mixture. The real trick is to get more air in the engine in order to burn the fuel - think super or turbo charging as a case on point.

The strato port is part of the intake cycle. If you can improve upon the flow of the strato system, you can increase the amount of air available for combustion. As I stated, there appears to be complete mixing of whatever is available in the cylinder by the time of combustion.

With the richen the mixture and get more fuel into the saw what about the MTronic and Auto tune saws ?,has anyone worked out how to adjust the electronics to acheave this ?.