drf255

BAD CAD

Do I run a huge risk if I just put some fuel in the intake boot?

Think I'm wimping out and dissembling it.

Think I'm wimping out and dissembling it.

Do I run a huge risk if I just put some fuel in the intake boot?

Think I'm wimping out and dissembling it.

It's dirko. The one I bought grey.

You will not get an accurate compression test until it has been run to clean the assembly lube out of it.This time I'm testing compression BEFORE I glue the engine back together.

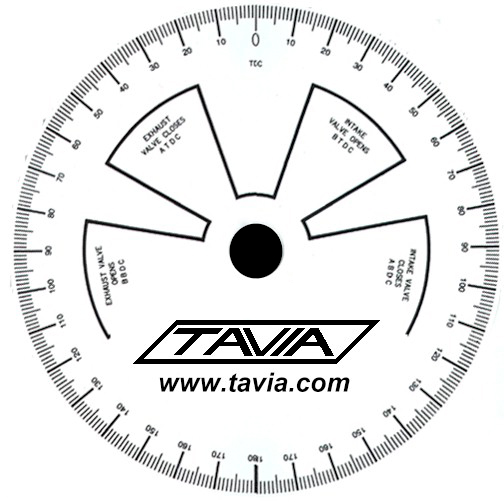

You're missing a very critical part. Until you degree that cylinder, and put the port timing where it should be, you're leaving a huge piece of the pie out of the equation. The transfers likely need raise, and the intake probably needs lowered. You will see gains for your port widening, but not what it could be. You can print out a paper degree wheel, sized to the diameter of your flywheel, and then simply glue it onto the fins. Make sure it's centered and that will be plenty good enough. Let us know what your stock port timing is and we can go from there.The ports have been played with already, just squared, enlarged and blended. I didn't mess with the timing.

I don't have the knowledge you do Brad. I figured I'd worsen whatever the engineers calculated more than I'd help.You're missing a very critical part. Until you degree that cylinder, and put the port timing where it should be, you're leaving a huge piece of the pie out of the equation. The transfers likely need raise, and the intake probably needs lowered. You will see gains for your port widening, but not what it could be. You can print out a paper degree wheel, sized to the diameter of your flywheel, and then simply glue it onto the fins. Make sure it's centered and that will be plenty good enough. Let us know what your stock port timing is and we can go from there.

Enter your email address to join: