marshall

ArboristSite Lurker

I've killed a saw or two, but not sure about the blow up. I have had an issue with vapor lock when pushing a saw really hard on a hot summer's day. August in Arkansas seems like it could be toasty.

Basically as the saw heats up, the gas starts to boil and isn't delivered to the engine correctly. Since the engine is gas starved, it doesn't get oil, further causing the engine to heat up and the piston will score.

Impossible to diagnose from the description above but if it fires up tomorrow okay that may be your problem.

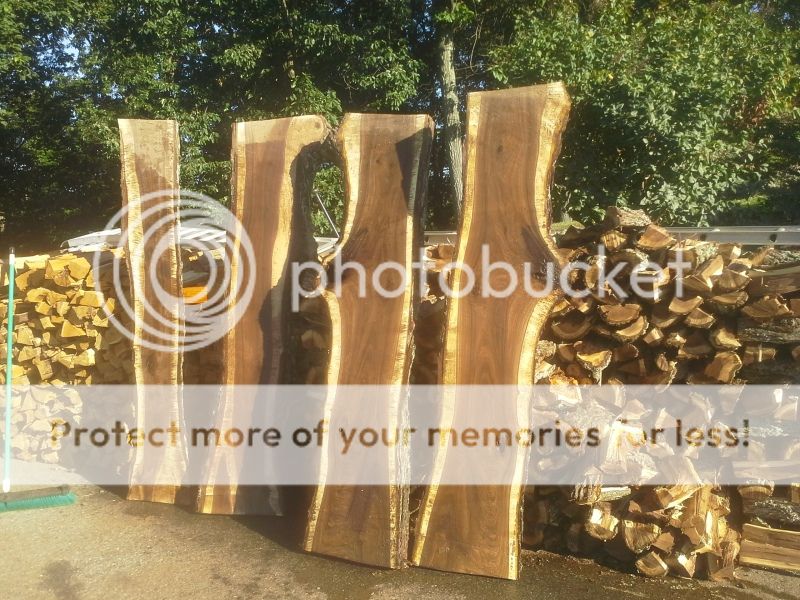

Either way, that is a serious slab.

Basically as the saw heats up, the gas starts to boil and isn't delivered to the engine correctly. Since the engine is gas starved, it doesn't get oil, further causing the engine to heat up and the piston will score.

Impossible to diagnose from the description above but if it fires up tomorrow okay that may be your problem.

Either way, that is a serious slab.