Welcome to the AS group.

- That is a nice looking pile of logs, fairly clean.

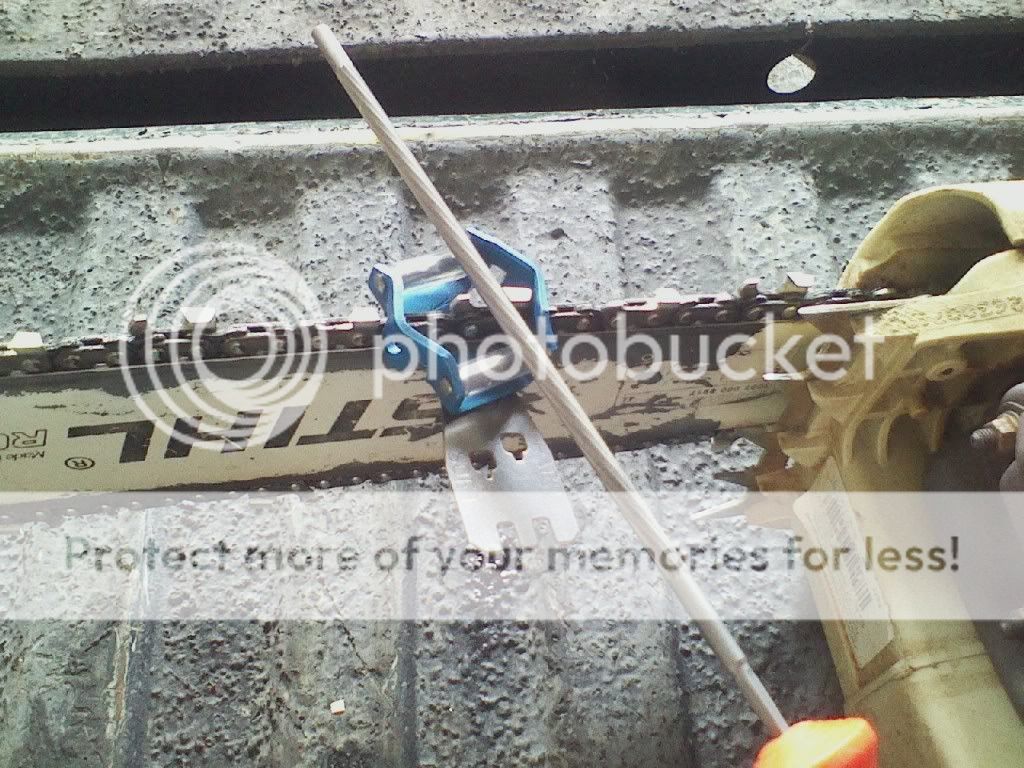

- In regards to chain: Stihl semi chisel chain is indeed set at a 30 degree angle, however the full chisel chain in set at 20 degrees. With dirty wood use semi chisel, with clean wood full chisel will cut faster & hold an sharp edge longer.

- Does your saw have a roller tipped bar or is it hard nosed. The hard nose bars are great with real dirty work but are said to use 20% more power to operate.

- Who will be feeding the OWB? My wife lets me harvest & prepare the wood, but does the majority of the stove feeding. Therefore I size the wood not by what the stove can handle but what my wife wants to handle.

- I have worked up a handout using MS Word for folks who are interested in buying or building a hydraulic wood splitter. It shows different styles & briefly covers pros & cons of each. If you would like a copy private mail me:

[email protected] & I would be happy to send you a copy.

- Even with using smaller logs, I still will split them at least once to speed up the drying time. I have learned over the years that if I cut & split the rounds right away, the wood cures much faster, it is easier to handle, & it is easier to not get overwhelmed. Working with fire wood should be a way to relax instead of stressing.

- If the person you purchased the saw from is knowledgeable about using one, PLEASE have him/her give you some instructions.

- When using a splitter always keep your hands on the sides of the rounds to where you can not end up with your hand/fingers caught between the round & the wedge or press plate.

- If using a dedicated horizontal splitter with the wedge fasted to the beam & the wood should get stuck on the wedge, do not try to wrestle it off. Take a 6-8' length of 1/4" chain & with the push slide/pressure plate up against the round, wrap the chain around the slide & piece of wood (But not the wedge) & retract the slide & pull the wood off the wedge using the power of the hydraulic cylinder. Most of injuries to hands/fingers while using splitters can be be avoided keeping these things in mind.

Hope burning wood become a pleasure for you & not just a chore!:smile2: John