I have 2 large oaks 36in diameter by probably 30 feet to the first set of branches that just blue down in resent storm I was trying to thank of uses for it .So i thought maybe i would use it for flooring in a cabin i am building my question is would it b worth my time or would it b better to just buy flooring .also i was thanking about milling 1in thick stacking sticker air drying and then planing down to 3/4in and then put tongue and grove on boards .ore should i just try to find different use fore oak. can i expect much warping and splitting if dried properly

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

oak for flooring

- Thread starter busybeazz

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

would it b worth my time or would it b better to just buy flooring .

Guess that would depend on what your time is worth ? Me, if I needed flooring, I would mill it from your trees.

I wouldnt want a hardwood floor that was only airdried, would want to kiln it too. If you use airdried wood for a floor , it will have cracks between the pieces that you can put a quarter in when you heat it in the winter.

woodshop

Addicted to ArboristSite

Guess that would depend on what your time is worth ? ...

Exactly. Many things, including flooring, are often cheaper if you count your time and tools needed to produce them, but that's not always the point. I've made flooring from scratch from milled wood, and I will tell you it is pretty labor intensive. Do you have or have access to a good woodshop full of machinery? Depending on how many feet of the stuff you intend to put a tongue and groove in, you also may need to upgrade your router or router table (I'm assuming you don't have a shaper, which would be the best way to do it). Not sure I completely agree with the assessment that if it's not kiln dried you will have cracks in the flooring. That's a function of how dry the stuff is when you put it down. The oak flooring I made that I was referring to above has been in somebodies living room for over 10 years and last time I was there was still as good as when it was laid, no cracks, just worn a bit. That was strait from milled red oak lumber that was air dried about 8 months (spring/summer/fall) here in the PA area.

I have a room in my garage i intend to make a kiln out of eventually and as of right now i have nothing but time as i am laid off and heavy equipment operator and with the economy the way it is i don"t know win i will b back to work .i do have a nice little work shop set up and i am always looking fore new tools .I always thank of tools as an investment.

I built my house about 10 years before I decided to build a sawmill < insert sad face here > and I bought my hardwood flooring from the local building supply. It was kiln dried but had been stored in an open shed and was 10-12% when layed. Most of the house is not bad, maybe 1 out of every 100 boards will shrink enough to have a crack that you could put a quarter in. But I use a fireplace insert and most every piece in front of it can hold up coins in the winter time. Most of the year there are no cracks though , they only show up after the heat has run a while. I am guessing if the floor had been 6-8% there would be "no" cracks ?

the westspartan

Addicted to ArboristSite

If you are not in a big hurry to get the cabin done, I would mill the flooring myself. Even if you have a few cracks, there is something nice about knowing you did it yourself from start to finish. I have been milling all of the building lumber and siding for a small workshop I am making out of blown down and dying trees on my land. It would have been easier to just buy the lumber, but there is something to be said for having a personal connection to the material,process, and final product. I don't know but I think that is why a lot of us are here.

Good Luck

Good Luck

Thats exactly how i feal thats y i am building the cabin ,for the pride i know i will have after it is finished . I love hard work and i have always dreamed of living in a log cabin .Now that the kids are all grown up and out i definatly dont nead all the space that i once neaded and am looking forward to living a much simpler life .it really would not hurt my fealling at all to not ever have to leave my little farm and b self suficent.

OK so i need to b on the look out for planer and maybe a shaper i figure i have at least 2 years until ill b ready for flooring any suggestions on model and type i should b looking fore i will probably buy used on the shaper as i sea they are not cheap and kind of a specialty tool that i may never have use fore in the future but you never know ill probably buy new planer as i feel ill use it often any suggestions for what to b on the look out for

ran3465

ArboristSite Operative

You could also contact sawmills. Depending on how much flooring you were planning you might be better off sending the rough cut to them and having them run it through a shaper and kiln drying it. It might be alot cheaper in the long run.

mossywyatt

New Member

I think that the look of air dried wood is better and more rich then kiln dried wood.

woodshop

Addicted to ArboristSite

OK so i need to b on the look out for planer and maybe a shaper i figure i have at least 2 years until ill b ready for flooring any suggestions on model and type i should b looking fore i will probably buy used on the shaper as i sea they are not cheap and kind of a specialty tool that i may never have use fore in the future but you never know ill probably buy new planer as i feel ill use it often any suggestions for what to b on the look out for

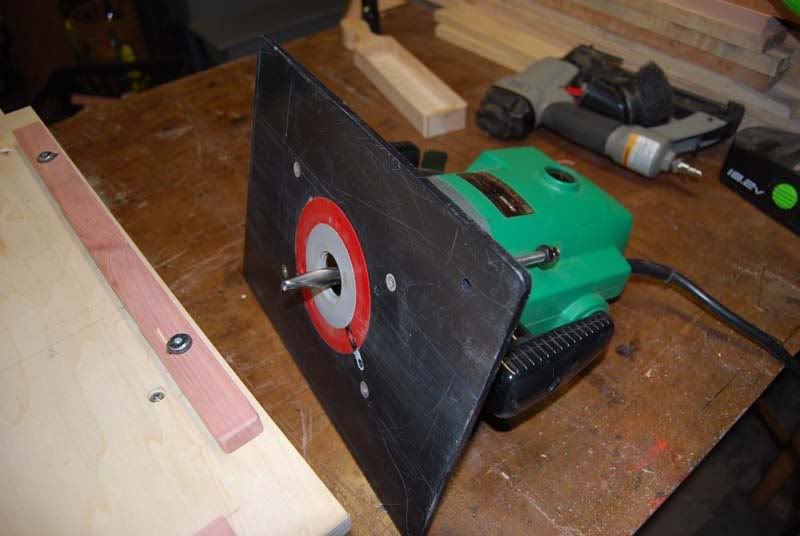

If you're only doing several hundred feet of this stuff, in other words you're not going to be making a career out of manufacturing tongue and groove flooring, then you can do nicely with a router on a router table. A 2-3HP router set up on a table with a fence is a much more versatile piece of machinery than a shaper in the long run. Also, in general even good quality router bits are cheaper than shaper tooling. You can build your own table and buy an insert to mount the router...similar to something like this one I built, but you wouldn't have to go to anywhere near that much trouble. Just a cutout in a plywood topped quick and diryt 2x4 table on which you could clamp a temporary fence would even work. The second pic shows the router attached to the base you would drop into that cutout, with your tongue/groove bit facing up.

rkwelp

ArboristSite Lurker

Another option for the tongue and grooving is to use a tablesaw with a dado blade. I have done this many time for wood projects,

Thanks for the info i was thanking maybe using a router or table saw i have both of them but do not have much experience with the router . I have not dun much fine carpentry . plenty of framing and general construction .

I was thanking about in stead of 1in planks cutting lets saw 3x beams and running through table saw to 1 inch thick i was thanking i would have a lot less waist since i do not own a band saw does this sound reasonable can i let the beams dry with out much warping or checking .

I was thanking about in stead of 1in planks cutting lets saw 3x beams and running through table saw to 1 inch thick i was thanking i would have a lot less waist since i do not own a band saw does this sound reasonable can i let the beams dry with out much warping or checking .

IndyIan

ArboristSite Operative

You are right about the waste with a chainsaw mill, but 3" thick planks will almost surely split and crack if you just air dry outside. It takes a well controlled kiln to dry thick stuff well.

I have an alaskan mill but for big jobs or nice hardwood I hire a portable band milller. Ask for a quote, to break down 3 big logs like that, into 1x4's or whatever width you want. 4 hours at $35/hour + bands(if needed) might be the best deal going for you.

I'd think too, if you have any kind of sub floor, 7/8" thick 4" wide white oak, doesn't need to be t&g anyways so you could just do a plank floor with brass screws, predrill the holes of course.

I have a cheap delta 12.5" planer that does 4" white oak just fine, I think you can find them new for $150. So for $300 you have a ton of your own white oak flooring, and a planer.

Ian

I have an alaskan mill but for big jobs or nice hardwood I hire a portable band milller. Ask for a quote, to break down 3 big logs like that, into 1x4's or whatever width you want. 4 hours at $35/hour + bands(if needed) might be the best deal going for you.

I'd think too, if you have any kind of sub floor, 7/8" thick 4" wide white oak, doesn't need to be t&g anyways so you could just do a plank floor with brass screws, predrill the holes of course.

I have a cheap delta 12.5" planer that does 4" white oak just fine, I think you can find them new for $150. So for $300 you have a ton of your own white oak flooring, and a planer.

Ian

I have a question about solid oak flooring. I have gotten several opinions on a few things.

1. What kind of end joints? Tongue and groove, Butt joint, or 45 each end?

2. What underlayment to use? Red paper, Thin foam insulation or nothing at all?

3. Nailing? Every row, every 2nd row or less?

I milled 500 feet of chestnut oak for a much needed living room with 60's shag carpet. Looking forward to the new floor.

1. What kind of end joints? Tongue and groove, Butt joint, or 45 each end?

2. What underlayment to use? Red paper, Thin foam insulation or nothing at all?

3. Nailing? Every row, every 2nd row or less?

I milled 500 feet of chestnut oak for a much needed living room with 60's shag carpet. Looking forward to the new floor.

I have a question about solid oak flooring. I have gotten several opinions on a few things.

1. What kind of end joints? Tongue and groove, Butt joint, or 45 each end?

2. What underlayment to use? Red paper, Thin foam insulation or nothing at all?

3. Nailing? Every row, every 2nd row or less?

I milled 500 feet of chestnut oak for a much needed living room with 60's shag carpet. Looking forward to the new floor.

I'm not an expert but my votes go for

1. T&G

2. Red paper

3. Every row

irishcountry

ArboristSite Guru

cant wait!!! Cool

1-T&G

2-not sure what red paper is, its been a few years since I was at a construction site. I used black roofing paper. I remember about 20 years ago I put cabinets in a house that the home owner was doing a lot of the work himself to save money, he used no paper at all and it was the biggest mess I have ever seen. EVERYWHERE you would step the floor squeaked.

3- Every row. I would think not nailing some rows would be giving it a chance to squeak ? ( Thats also why I would T&G the ends )

I have done over a dozen houses over the years ( been a while though ) and used both staples and nails. If I had a choice I would want staples.

2-not sure what red paper is, its been a few years since I was at a construction site. I used black roofing paper. I remember about 20 years ago I put cabinets in a house that the home owner was doing a lot of the work himself to save money, he used no paper at all and it was the biggest mess I have ever seen. EVERYWHERE you would step the floor squeaked.

3- Every row. I would think not nailing some rows would be giving it a chance to squeak ? ( Thats also why I would T&G the ends )

I have done over a dozen houses over the years ( been a while though ) and used both staples and nails. If I had a choice I would want staples.

1-T&G

2-not sure what red paper is, its been a few years since I was at a construction site. I used black roofing paper. I remember about 20 years ago I put cabinets in a house that the home owner was doing a lot of the work himself to save money, he used no paper at all and it was the biggest mess I have ever seen. EVERYWHERE you would step the floor squeaked.

3- Every row. I would think not nailing some rows would be giving it a chance to squeak ? ( Thats also why I would T&G the ends )

I have done over a dozen houses over the years ( been a while though ) and used both staples and nails. If I had a choice I would want staples.

Red paper or rosin paper would let the floor move without binding it. If you are over a crawl space or another space that has moisture, you would probably be better off with roofing paper as it has moisture barrier qualities.

Oak is hard and is more prone to splitting than some other flooring types. I can't remember which fastner type was more likely to split the tongue, staple or nail. It does not happen often, but if you are doing it yourself from tree to stock, it could add time. I think they generally count on 20% waist when you buy flooring. Since you are cutting your own, I would think you will have less waist but I don't know how much.

Similar threads

- Replies

- 66

- Views

- 3K

- Replies

- 11

- Views

- 1K

- Replies

- 54

- Views

- 3K

- Replies

- 4

- Views

- 762