Ironworker

Addicted to ArboristSite

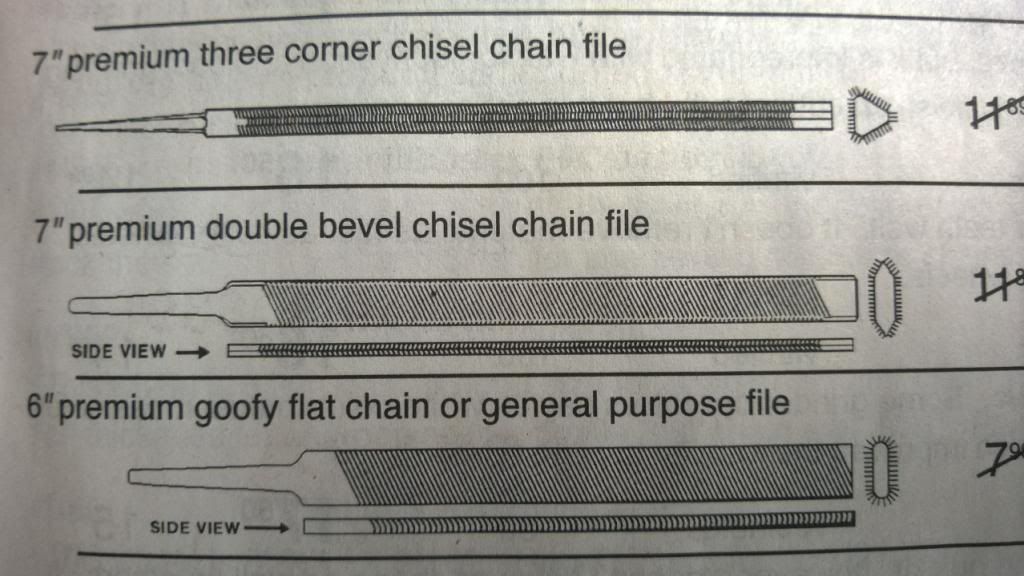

Bought a square chisel to see what they're about and would like some info on hand sharpening. Do those triangle shaped files work?

Bought a square chisel to see what they're about and would like some info on hand sharpening. Do those triangle shaped files work?

I started off using the "triangular" Pferd file, and like it. I've tried the flat file a bit and it seems awkward, but I plan on giving it a real chance the next time I have to dress the chain. I suspect there is a large element of being more comfortable with what you got used to first.Bought a square chisel to see what they're about and would like some info on hand sharpening. Do those triangle shaped files work?

Why is that called a 6 side when I only see 4. Are you sharpening both sides of the cutter with each stroke.this is a cutter done with a 6 sided file View attachment 353427

this is rough angle i use to hold the flat file ,the bottom of the file is lightly grazing the tie strap to get my angles ,and with square you file outside in to get the corner lined up View attachment 353428

Thanks, hope you didn't smash your thumb getting a good pic.having a hard time getting a close up ,can kind of see the 6 sides here View attachment 353438 View attachment 353438 View attachment 353440

Why is that called a 6 side when I only see 4. Are you sharpening both sides of the cutter with each stroke.

What happened to your thumb Brian. I bet that hurt.

opcorn:

There's folks around here that have forgot more than I know about these fancy fast chains...Come on ,show us that top secret magic chain you hoard .........

I think you'll enjoy playing with it John...I had to order a piston from Bailys so I ordered a couple of those files, yesterday I sat down with a .325 on a 16" bar that had been round filed and changed it to square, I thought it was easyer than rnd fileing, I haven't put it to wood yet tho.

John

you know how to fix thatAnd all muh files are dull...

There's folks around here that have forgot more than I know about these fancy fast chains...

I'd just call mine serviceable...

And all muh files are dull...

Enter your email address to join: