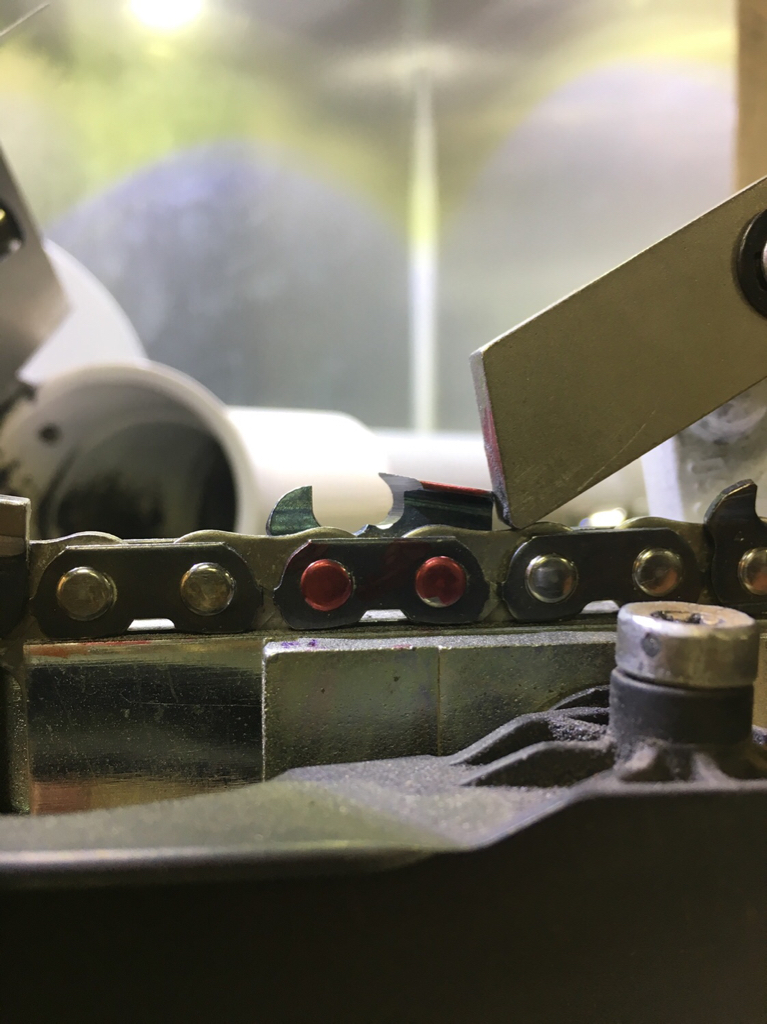

I've been reading this thread and wondered why some guys are experiencing burned cutters using CBN. I have to really crank down on mine to cause that issue. But I can see from some of the pics in the recent thread posts that the CBN wheels are from solid steel blanks. Mine is made from steel blank as well but has multiple cutouts near the edges with gaps machined through the edge of the wheel from each cutout hole, which breaks contact between the abrasive CBN finish and the cutter as the wheel turns. It also whips up quite a breeze due to the cutouts, which contributes more cooling. It is similar to a dinasaw cyclone in concept. This might explain the difference.

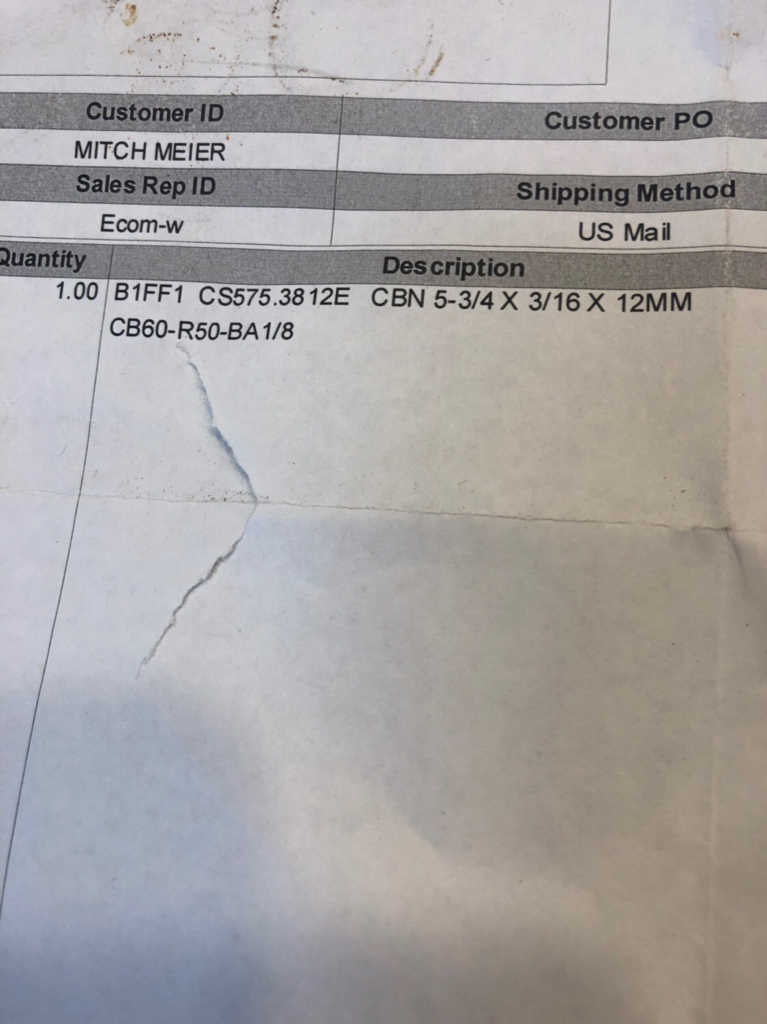

My wheel came from US Diamond. I think it is 80 grit with the 1FF1 profile. I never have needed to dress it which is a good thing because it did not come with a dressing stick.

I've used the CBN and hand filing as well for several years on 3/8 pitch and don't see a real difference between them in the field. You need a little experience with either one to get consistently good results. The difference in my experience is that a grinder with a CBN wheel will shape up a rocked chain in a hurry. I use a pink wheel for my .325 stuff, and dress it before each use to get the wheel profile correct. It's fine but slower and tends to burn the cutters if I'm too aggressive with it. I've never upgraded this one to CBN because I do not use .325 that much.

For touch up work I now mostly file a chain on a filing vise. But if the chain needs more than that, it sees a grinder first, then it's filed if I think it needs a finishing touch or to check and adjust depth gauges, which I always do with a file.